A nanotube-based nanopore detection system and its preparation method and application

A detection system and nanotube technology are applied to a nanopore detection system for detecting long-chain polymers and the field of preparation thereof, which can solve the problems of poor mechanical stability of two-dimensional material films, reduced signal-to-noise ratio, and low spatial resolution, etc. The effect of good mechanical stability, improved resolution and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

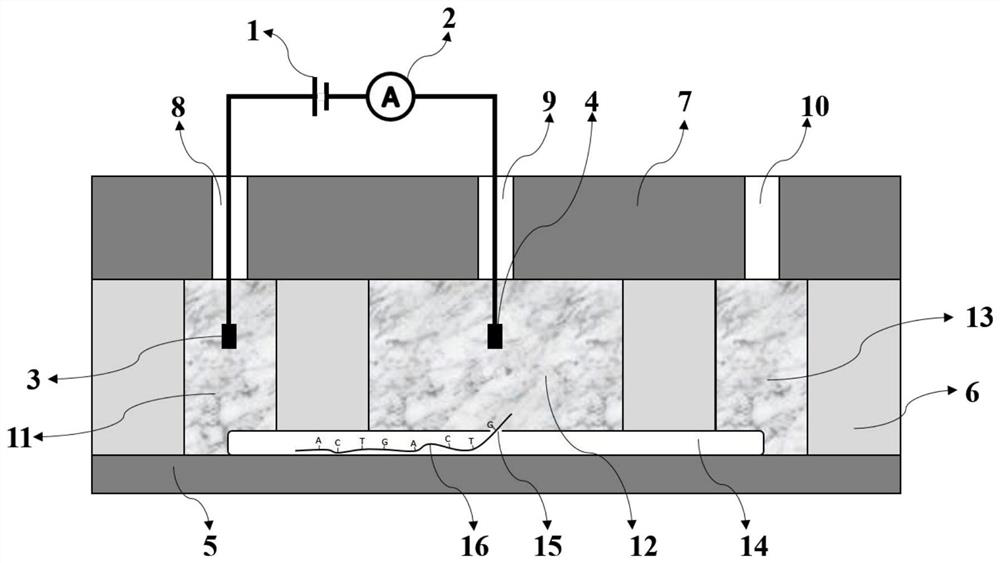

[0044] This embodiment provides a nanopore detection system based on single-walled carbon nanotubes. The specific implementation is as follows:

[0045] It is 1-10nm to grow diameter on the substrate 5 surface that has silicon dioxide thin film, and length is 500-1000 μm nanotube 14, on above-mentioned substrate 5 with nanotube 14, spin-coat negative photoresist, use light The engraving processing method is to process a negative photoresist microchannel structure 6 with a thickness of 20 μm and a width of 7 μm on the selected nanotube 14 with a diameter of 2 nm and a length of 500 μm to form the first chamber 11 and the second chamber. Chamber 12 and third chamber 13.

[0046]There is no communication between the first chamber 11 and the second chamber 12 , and between the second chamber 12 and the third chamber 13 , and the communication between the first chamber 11 and the third chamber 13 is only through the nanotube 14 . The two ends of the nanotube 14 are treated with a...

Embodiment 2

[0051] This embodiment provides a nanopore detection system based on boron nitride nanotubes. The specific implementation manner is as follows:

[0052] Dispersed on the surface of the substrate 5 with a diameter of 300-500nm and a length of 10-90 μm nanotubes 14, spin-coat positive photoresist on the above-mentioned substrate with nanotubes. A positive photoresist microchannel structure 6 with a thickness of 15 μm and a width of 8 μm is processed on the nanotube 14 with a thickness of 400 nm and a length of 20 μm to form a first chamber 11 , a second chamber 12 and a third chamber 13 .

[0053] There is no communication between the first chamber 11 and the second chamber 12, the second chamber 12 and the third chamber 13, and only the selected nanotubes 14 communicate between the first chamber 11 and the third chamber 13 . The two ends of the nanotube 14 are treated with a focused ion beam to ensure that the two ends of the nanotube 14 are not blocked. The part of the nano...

Embodiment 3

[0058] This embodiment provides a nanopore detection system based on multi-walled carbon nanotubes. The specific implementation manner is as follows:

[0059] Growth diameter is 10-90nm on the surface of substrate 5, and length is 100-500 μm nanotube, on above-mentioned substrate 5 with nanotube, spin coating negative photoresist, with the method for photolithographic processing, in selected A negative photoresist microchannel structure 6 with a thickness of 25 μm and a width of 5 μm is processed on the nanotube 14 to form a first chamber 11 , a second chamber 12 and a third chamber 13 .

[0060] There is no communication between the first chamber 11 and the second chamber 12 , and between the second chamber 12 and the third chamber 13 , and the communication between the first chamber 11 and the third chamber 13 is only through the nanotube 14 . The two ends of the nanotube 14 are treated with a focused ion beam to ensure that the two ends of the nanotube 14 are not blocked. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com