A kind of sealing tape for double-glass photovoltaic module and preparation method thereof

A sealing tape and double-glass photovoltaic technology, applied in the field of sealants, can solve the problems of glue liquid prone to defects, waste, weak sealing, etc., and achieve the effect of blocking moisture penetration, reducing production costs, and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

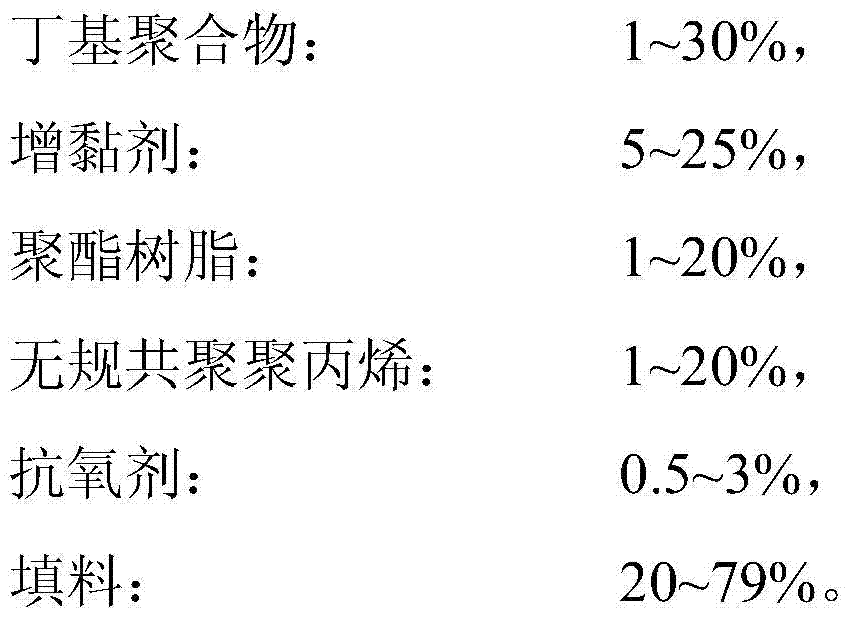

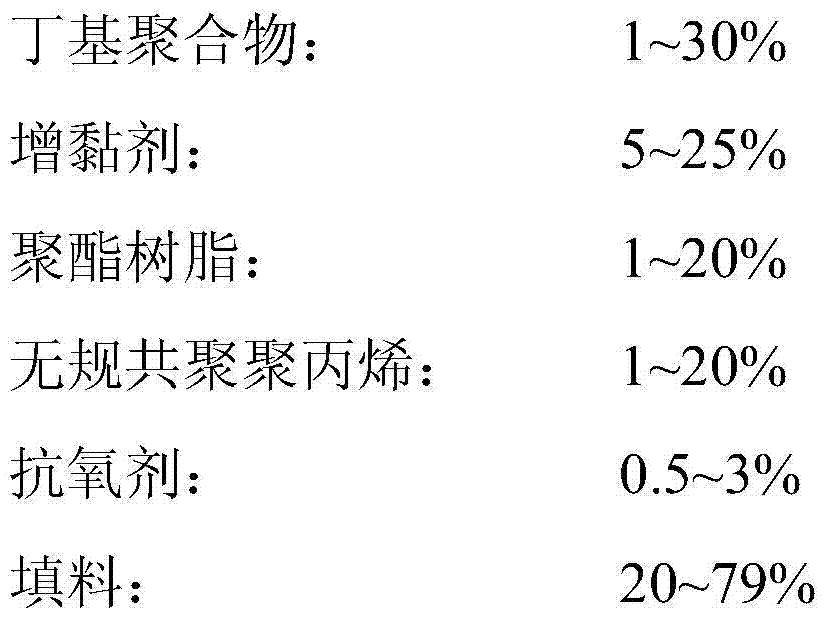

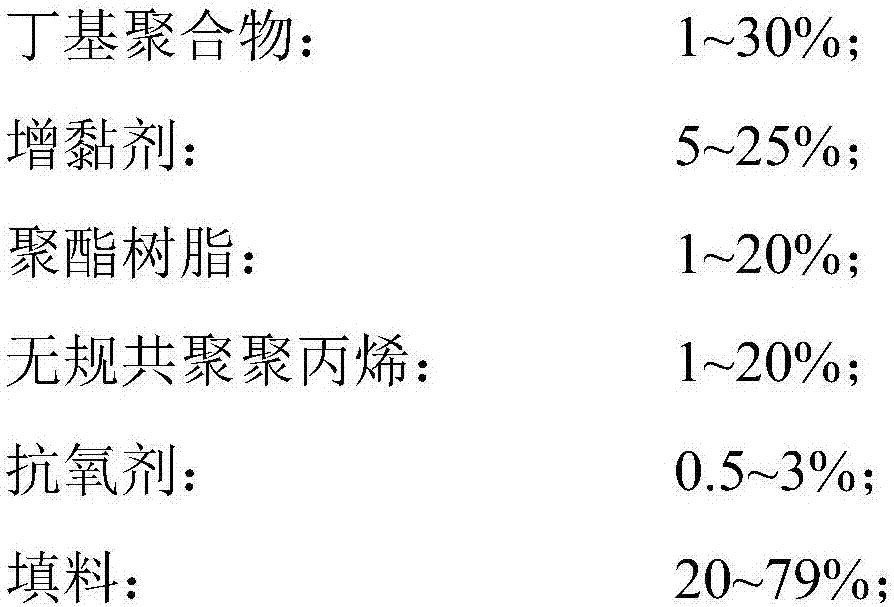

[0054] A kind of preparation method as aforementioned sealing tape, it comprises the steps:

[0055] The butyl polymer is successively carried out rubber mixing;

[0056] Adding polyester resin, tackifier, filler, antioxidant, random copolymerized polypropylene, no requirement for the order of addition, mixing the rubber to obtain the primary material of the sealing tape, and then extruding and calendering to make a rubber strip.

[0057] The mixing temperature is less than 180°C, and the extrusion temperature is controlled at less than 180°C.

[0058] The polyester resin in the present invention can choose DYNACOLL 7000 for use.

Embodiment 1

[0060] Butyl rubber 10%, polyisobutylene 10%, phenolic resin 20%, polyester resin 10%, random copolymer polypropylene 10%, antioxidant 264 1%, ground calcium carbonate 25%, talc 9%, carbon Black 5%.

Embodiment 2

[0062] Butyl rubber 10%, polybutadiene rubber 5%, polyisobutylene 5%, phenolic resin 20%, petroleum resin 5%, polyester resin 5%, random copolymer polypropylene 10%, antioxidant 2246 1%, Antioxidant 1010 1%, ground calcium carbonate 30%, talcum powder 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com