Installation and construction technology of large-diameter hdpe plastic-steel winding pipe

A construction technology and large diameter technology, applied in pipeline laying and maintenance, pipeline heating/cooling, pipes/pipe joints/pipe fittings, etc., can solve problems such as uneven heating, achieve complete melting, good adhesion effect, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

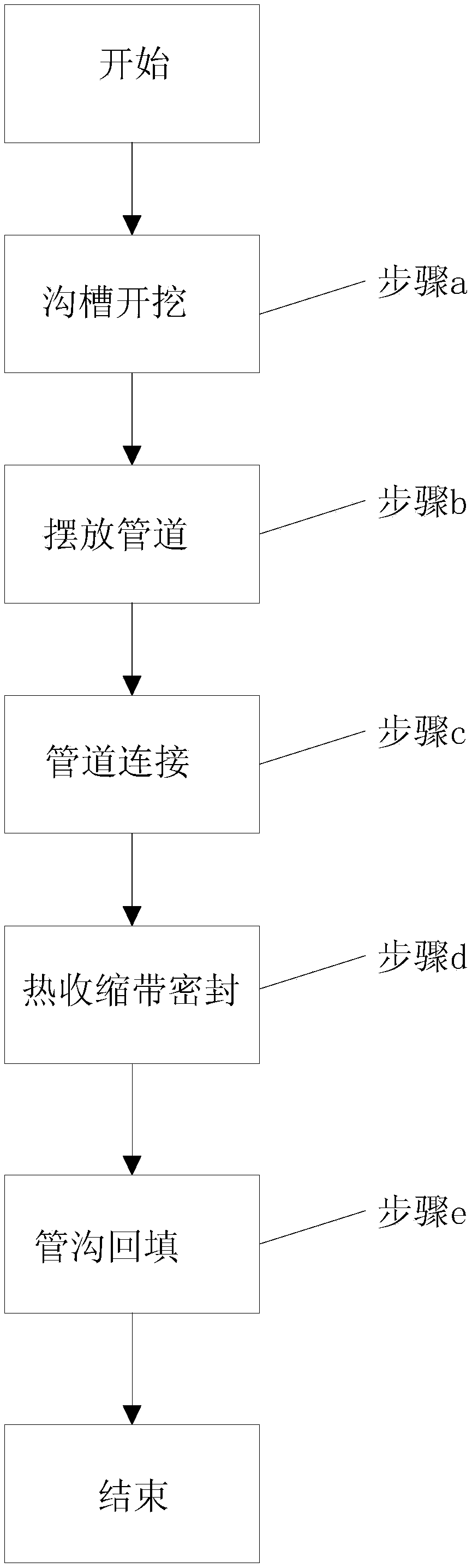

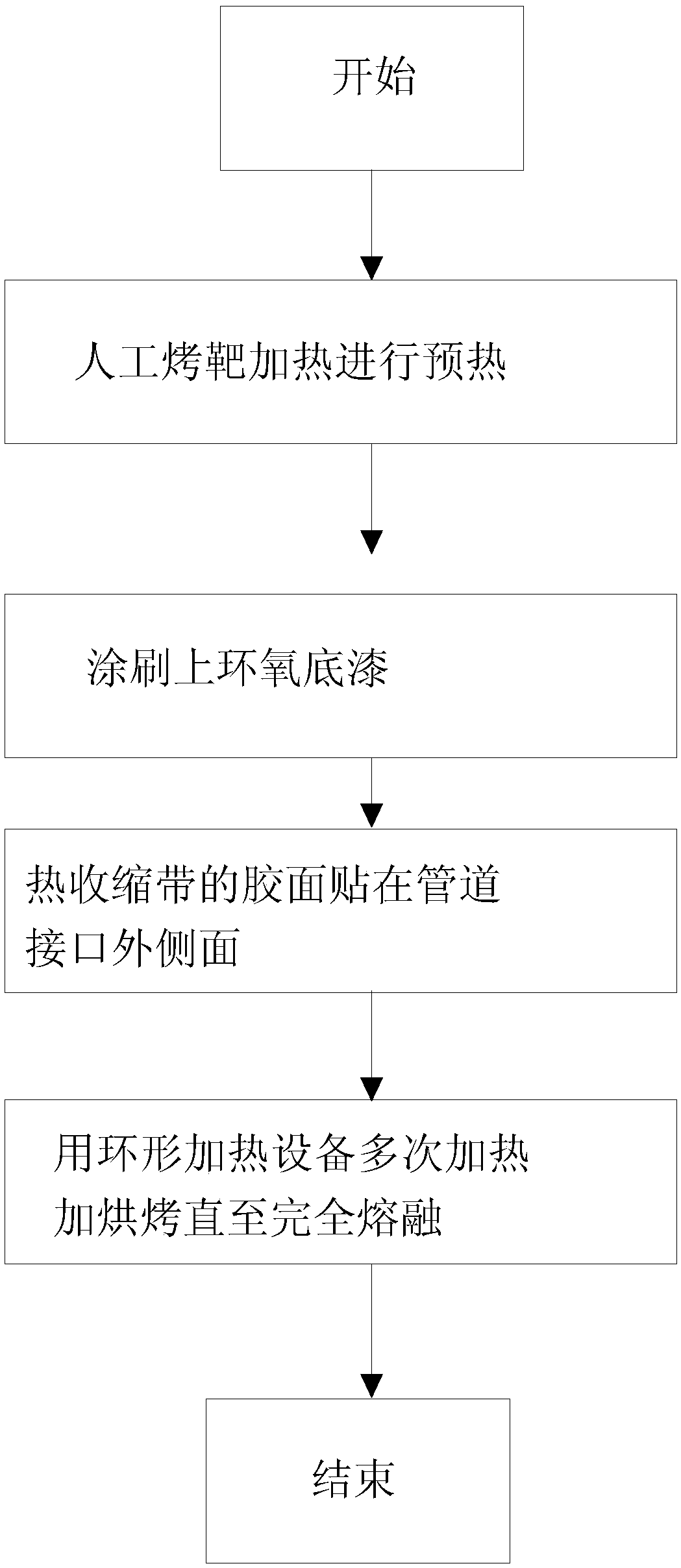

[0031] A large-diameter HDPE plastic-steel winding pipe 1 installation and construction process includes the following steps:

[0032] Such as figure 2 As shown, step a: trench excavation, excavate the pipe trench according to the layered combination groove, the deepest excavation of the pipe trench is more than 3m, and the soil condition is poor, excavate according to the layered combination groove, tamp the pipe foundation and lay the bedding 150mm natural graded sand or medium and coarse sand and compacted to increase the contact area between the bottom of the pipeline 1 and the foundation, protect the pipeline 1, and remove debris in the trench;

[0033] Step b: Place the pipeline 1 in the trench, which can be done manually or by a crane, keep parallel to prevent it from entering the trench, and cut the corresponding length according to the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com