Vehicle laminated glass with low-resistance region in heating region

A laminated glass, low-resistance technology, used in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as low busbar height, heating, and uneven heating, reduce the risk of burnout, and solve uneven heating. , the effect of reducing the chance of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

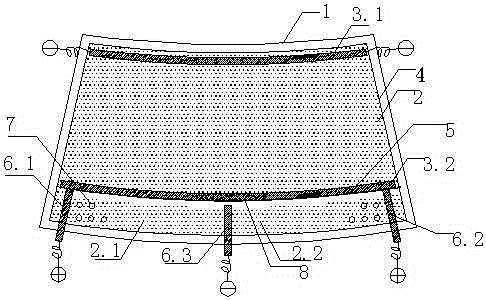

[0068] As shown in the figure, the solution includes a glass substrate 1, which includes an electrothermal film layer 2 that removes the film around the periphery to prevent oxidation and forms the film removal boundary 4, and the wiper rest position heating zones 2.1, 2.2 for auxiliary heating; Two roughly parallel upper busbars 3.1 and lower busbars 3.2 are arranged on the film layer 2; a non-conductive partition bar 5 is arranged under the lower busbar, so that the heating area at the rest position of the wiper is not connected to the lower busbar, and at the same time extends to the surrounding film removal area, The non-conductive dividing strip can be formed by methods such as laser film removal, physical masking before coating, or chemical etching, and is preferably cut by laser; the non-conductive dividing strip 5 can have a certain width, or can be a thin line. At least one second busbar 6.1 or 6.2 is drawn out from the heating zone at the rest position of the wiper to...

Embodiment 2

[0071] figure 2 for similar figure 1 structure, when the distance between the upper and lower busbars is less than or equal to 800mm, it is preferable to use a similar figure 2 The structure does not apply a low-resistance area at the position of the glass bulk. Others are with embodiment 1.

Embodiment 3

[0073] image 3 for similar figure 2 structure, when the distance between the upper and lower busbars is less than or equal to 700mm, it is preferable to use a similar image 3 The structure of the busbar under the glass does not need to set a mesh structure. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com