Yarn sizing device for spinning

A yarn and height adjustment device technology, which is applied in the direction of processing textile material equipment configuration, processing textile material carriers, processing textile material containers, etc., can solve the problem that the sizing device cannot adjust the degree of sizing and dyeing, the operation is inconvenient, and the yarn sizing is affected effect and other issues, to achieve the effect of improving structural stability, ensuring parallelism, and the overall structural design is compact and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

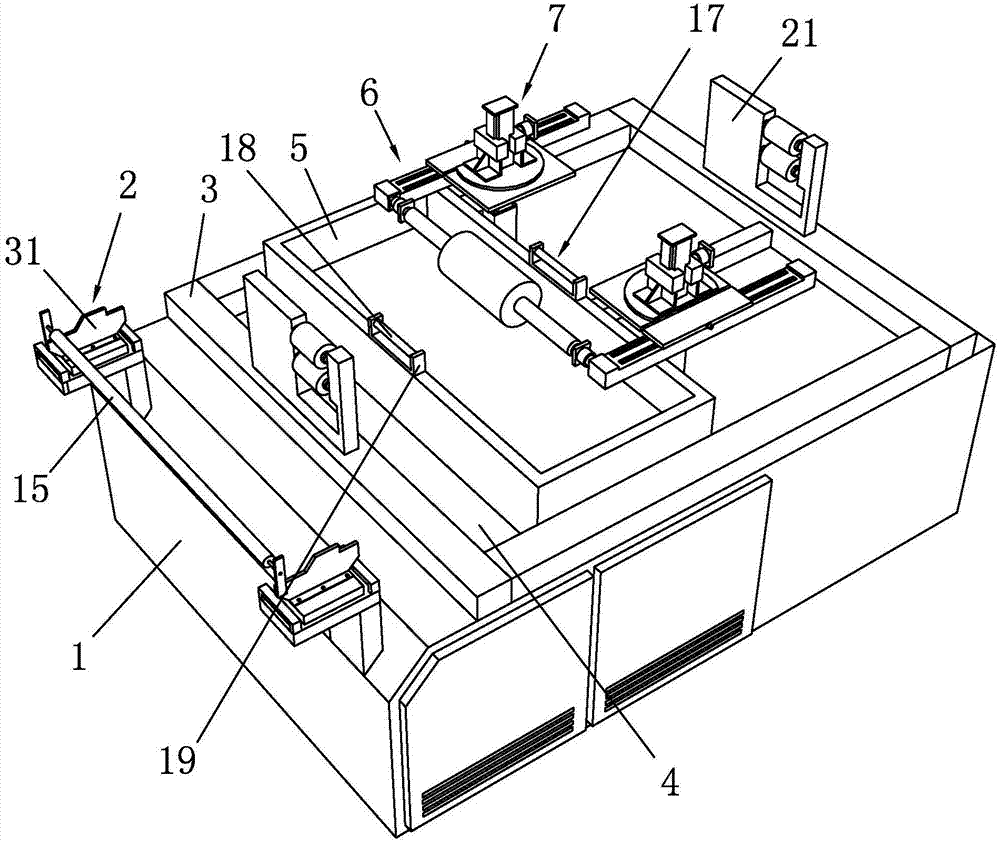

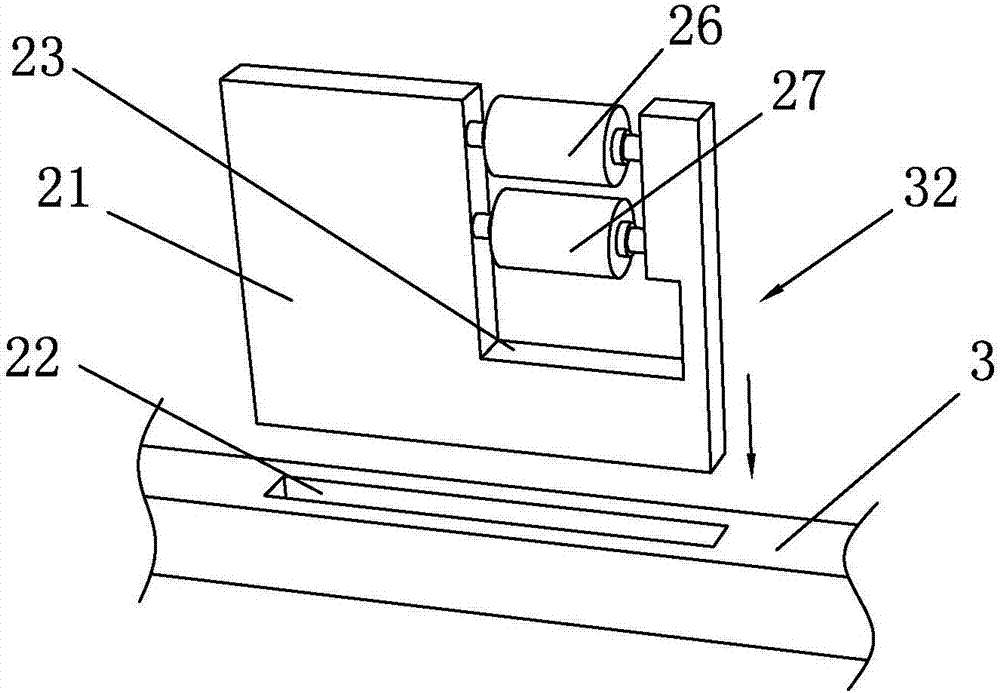

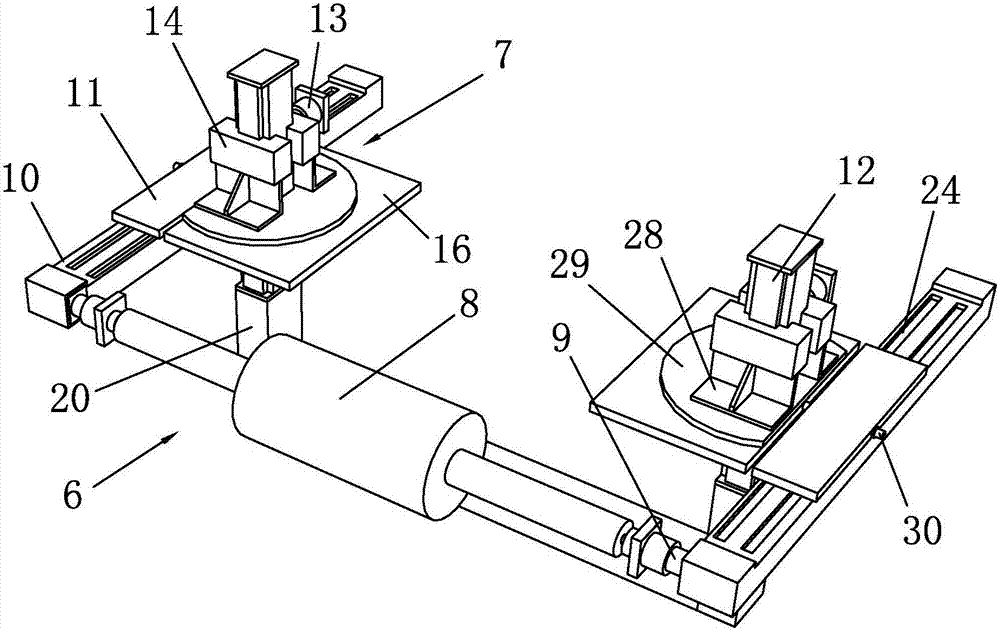

[0028] Such as Figure 1 to Figure 7 As shown, it is a textile yarn sizing device of the present invention, including a workbench 1, a sizing assembly and a material receiving assembly 2, both of which are fixedly connected to the workbench 1, and the workbench 1 is provided with a convex Platform 3, the left and right sides of boss 3 are all provided with guide device 32, and guide device 32 comprises material guide frame 21 and material guide roller, and material guide frame 21 is provided with mounting groove 23, and material guide roller is arranged on In the mounting groove 23, the guide roller comprises a first guide roller 26 and a second guide roller 27, the first guide roller 26 is positioned above the second guide roller 27, and the guide frame 21 can facilitate the installation of the guide device 32. Installed and fixed, the transmission direction of the yarn can be guided by the first material guide roller 26 and the second material guide roller 27, so that the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com