A kind of coloring method of iron-based galvanized layer or galvanized layer color metallography

A technology of color metallography and galvanized layer, which is applied in the preparation of test samples, etc., can solve the problems of grain boundary display clarity, phase distinction, degree of accuracy and poor display result accuracy, and achieve good coloring effect, simple steps and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

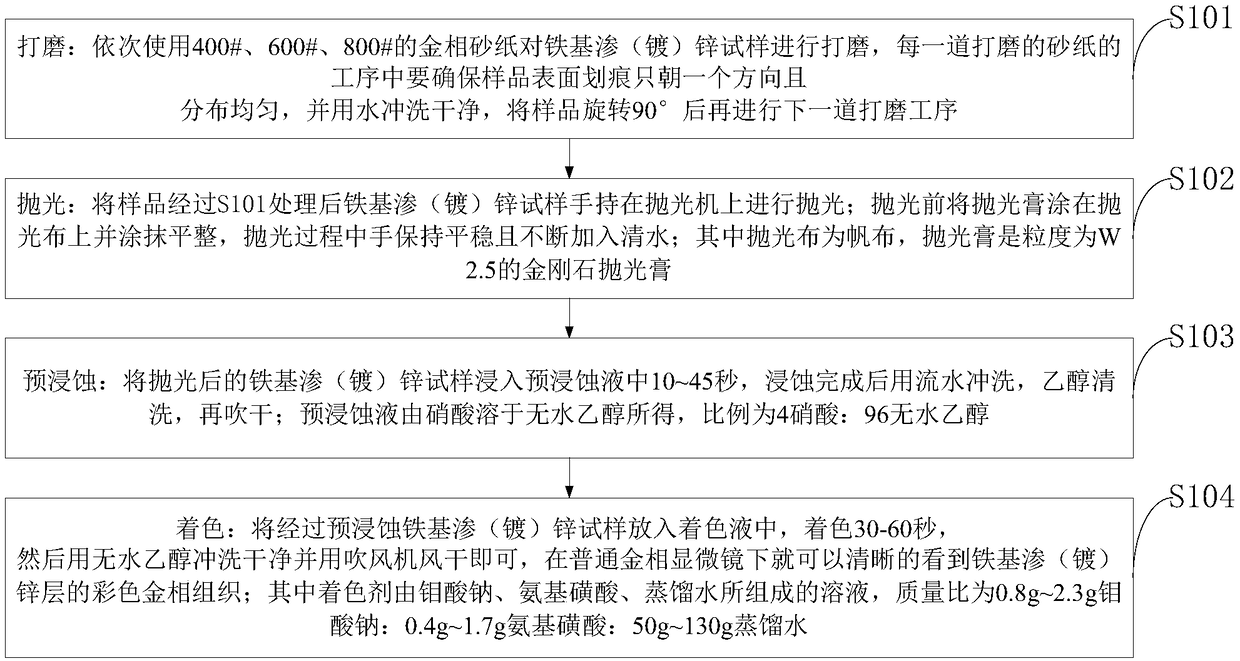

[0030] The iron-based galvanizing layer or the coloring method of the color metallography of the galvanized layer provided by the embodiment of the present invention comprises the following steps:

[0031] Grinding: use 400#, 600#, 800# metallographic sandpaper to polish the iron-based galvanized (galvanized) sample in sequence, and ensure that the scratches on the surface of the sample only face one direction and are evenly distributed in each grinding process , and rinse with water, rotate the sample 90° before proceeding to the next grinding process;

[0032] Polishing: After the sample is polished, the iron-based galvanized (plated) galvanized sample is held on a polishing machine for polishing; before polishing, the polishing paste is applied to the polishing cloth and smoothed, and the hand is kept steady during the polishing process and water is continuously added; among them The polishing cloth is canvas, and the polishing paste is diamond polishing paste with a partic...

Embodiment 2

[0036] The iron-based galvanizing layer or the coloring method of the color metallography of the galvanized layer provided by the embodiment of the present invention comprises the following steps:

[0037] Grinding: use 400#, 600#, 800# metallographic sandpaper to polish the iron-based galvanized (galvanized) sample in sequence, and ensure that the scratches on the surface of the sample only face one direction and are evenly distributed in each grinding process , and rinse with water, rotate the sample 90° before proceeding to the next grinding process;

[0038] Polishing: After the sample is polished, the iron-based galvanized (plated) galvanized sample is held on a polishing machine for polishing; before polishing, the polishing paste is applied to the polishing cloth and smoothed, and the hand is kept steady during the polishing process and water is continuously added; among them The polishing cloth is canvas, and the polishing paste is diamond polishing paste with a partic...

Embodiment 3

[0042] The iron-based galvanizing layer or the coloring method of the color metallography of the galvanized layer provided by the embodiment of the present invention comprises the following steps:

[0043] Grinding: use 400#, 600#, 800# metallographic sandpaper to polish the iron-based galvanized (galvanized) sample in sequence, and ensure that the scratches on the surface of the sample only face one direction and are evenly distributed in each grinding process , and rinse with water, rotate the sample 90° before proceeding to the next grinding process;

[0044] Polishing: After the sample is polished, the iron-based galvanized (plated) galvanized sample is held on a polishing machine for polishing; before polishing, the polishing paste is applied to the polishing cloth and smoothed, and the hand is kept steady during the polishing process and water is continuously added; among them The polishing cloth is canvas, and the polishing paste is diamond polishing paste with a partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com