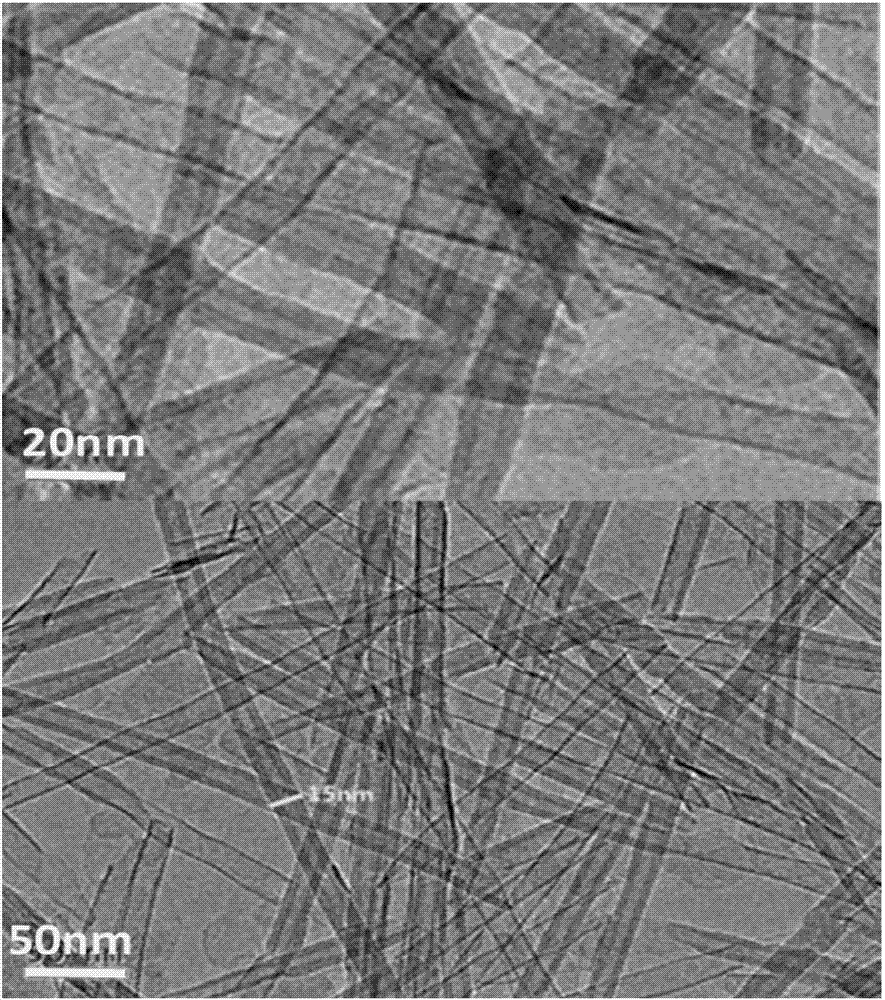

Oil-soluble nano-magnesium silicate hydroxide and preparation method thereof

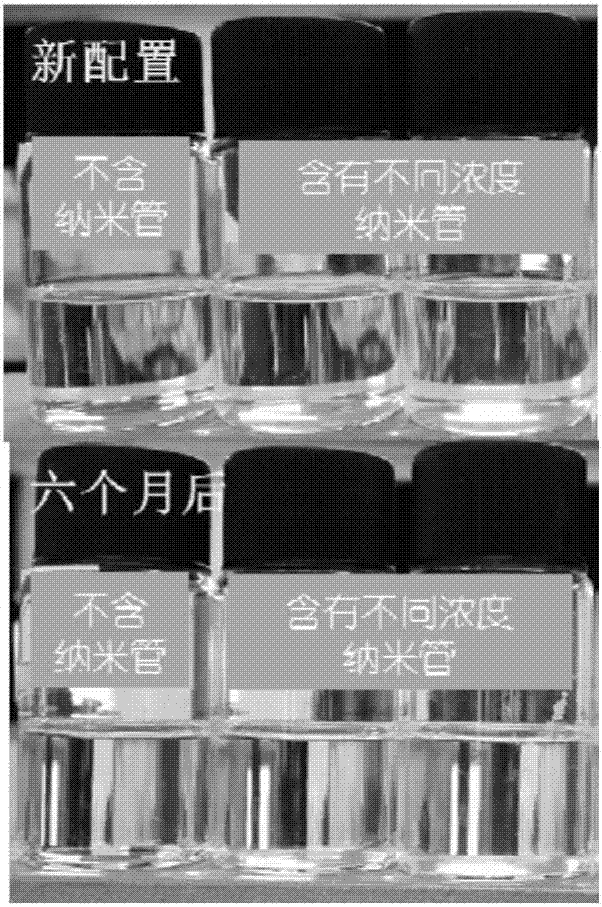

A hydroxy magnesium silicate, oil-soluble technology, applied in the field of chemistry, can solve the problem that natural serpentine powder cannot stably disperse base oil, etc., and achieve the effects of easy industrial scale-up production, uniform scale and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Utilize the method for the embodiment of the present invention to synthesize oil-soluble nano-hydroxy magnesium silicate, the specific process is as follows:

[0050] 1) Weigh 2.05g of sodium nitrate, 0.41g of sodium silicate, and 10.3g of sodium hydroxide and dissolve them in 200ml of water, and stir evenly;

[0051] 2) The above mixed solution was heated to 180 degrees and kept for 24 hours, then cooled to room temperature to obtain a white liquid;

[0052] 3) Centrifuge the above white liquid to obtain a white precipitate, which is dissolved in water and ethanol to wash the white precipitate alternately;

[0053] 4) Weigh 2.0 g of the white precipitate and dissolve it in 15 ml of ethanol, heat to 70 degrees, add 0.1 g of SG-SiF17 silane coupling agent dropwise, stir, react for 2 hours, cool to room temperature, and obtain a white liquid;

[0054] 5) centrifuging the white liquid obtained in step 4) to obtain a white precipitate;

[0055] 6) Washing the white precip...

Embodiment 2

[0057] Utilize the method for the embodiment of the present invention to synthesize oil-soluble nano-hydroxy magnesium silicate, the specific process is as follows:

[0058] 1) Weigh 2.05g of sodium nitrate, 0.82g of sodium silicate, and 20.5g of sodium hydroxide and dissolve them in 200ml of water, and stir evenly;

[0059] 2) The above mixed solution was heated to 200 degrees and kept for 21 hours, then cooled to room temperature to obtain a white liquid;

[0060] 3) Centrifuge the above white liquid to obtain a white precipitate, which is dissolved in water and ethanol to wash the white precipitate alternately;

[0061] 4) Weigh 2.0 g of the white precipitate and dissolve it in 15 ml of ethanol, heat to 70 degrees, add 0.4 g of SG-Si187 silane coupling agent dropwise, stir, react for 1.5 hours, cool to room temperature, and obtain a white liquid;

[0062] 5) centrifuging the white liquid obtained in step 4) to obtain a white precipitate;

[0063] 6) Washing the white prec...

Embodiment 3

[0065] Utilize the method for the embodiment of the present invention to synthesize oil-soluble nano-hydroxy magnesium silicate, the specific process is as follows:

[0066] 1) Weigh 2.05g of sodium nitrate, 1.23g of sodium silicate, and 30.8g of sodium hydroxide and dissolve them in 200ml of water, and stir evenly;

[0067] 2) The above mixed solution was heated to 210 degrees and kept for 19 hours, then cooled to room temperature to obtain a white liquid;

[0068] 3) Centrifuge the above white liquid to obtain a white precipitate, which is dissolved in water and ethanol to wash the white precipitate alternately;

[0069] 4) Weigh 2.0 g of the white precipitate and dissolve it in 15 ml of ethanol, heat to 70 degrees, add 0.8 g of SG-Si191 silane coupling agent dropwise, stir, react for 1 hour, and cool to room temperature to obtain a white liquid;

[0070] 5) centrifuging the white liquid obtained in step 4) to obtain a white precipitate;

[0071] 6) Washing the white preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com