A device for reusing crushed soap

A soap and rotating rack technology, used in the field of household appliances, can solve problems such as breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

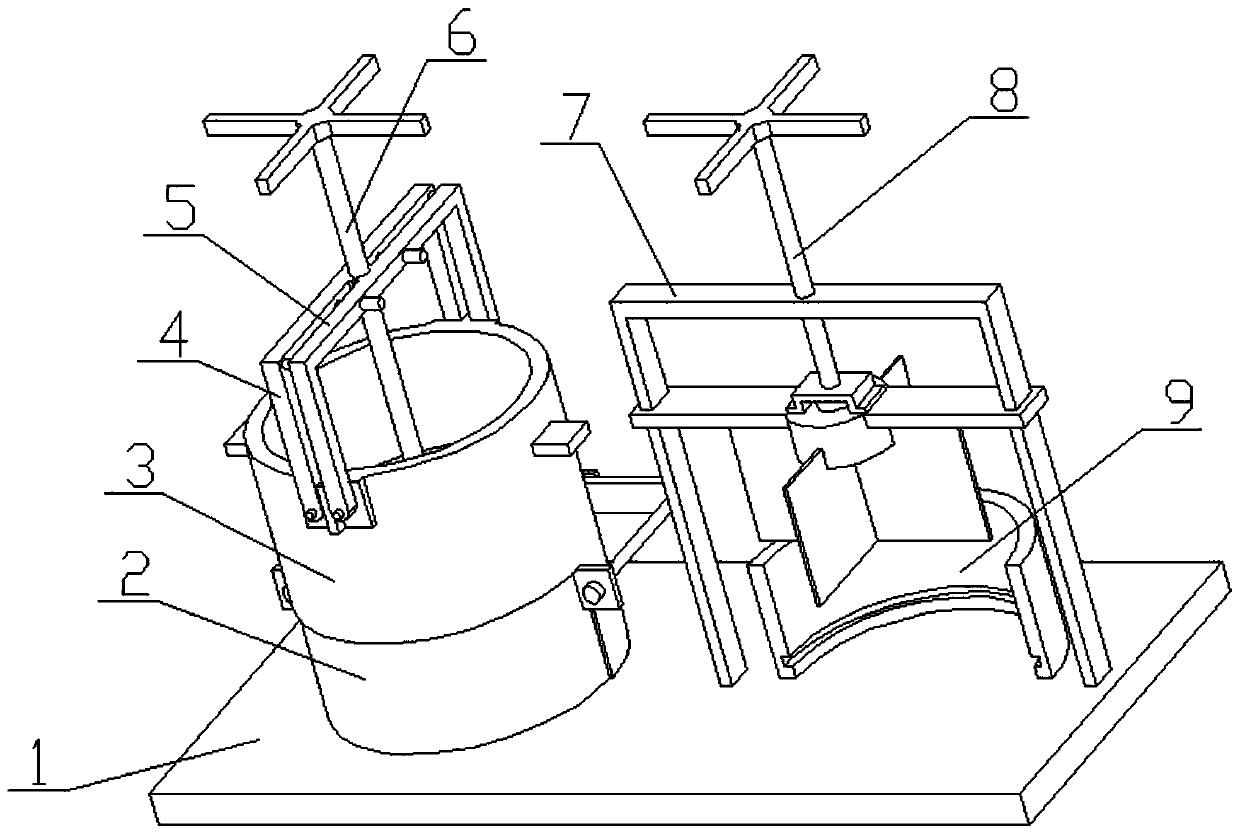

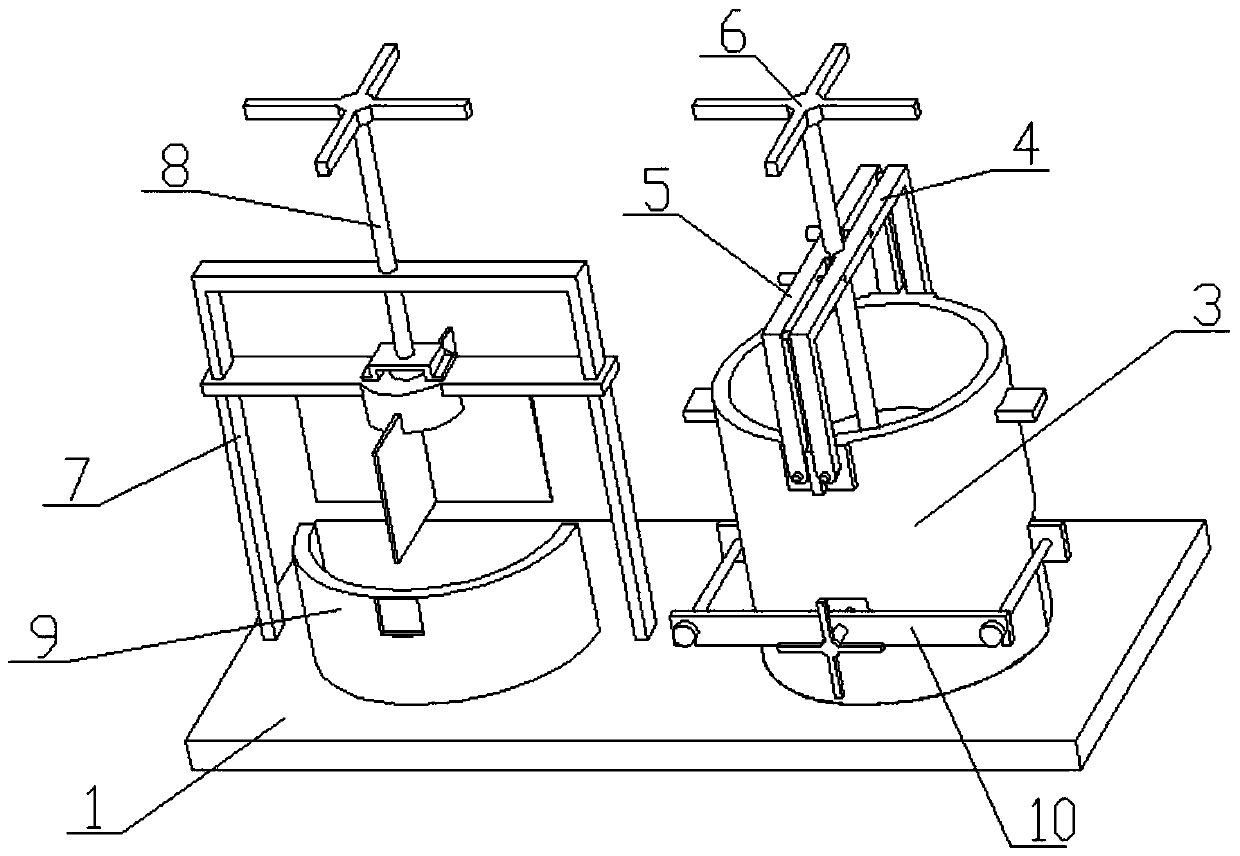

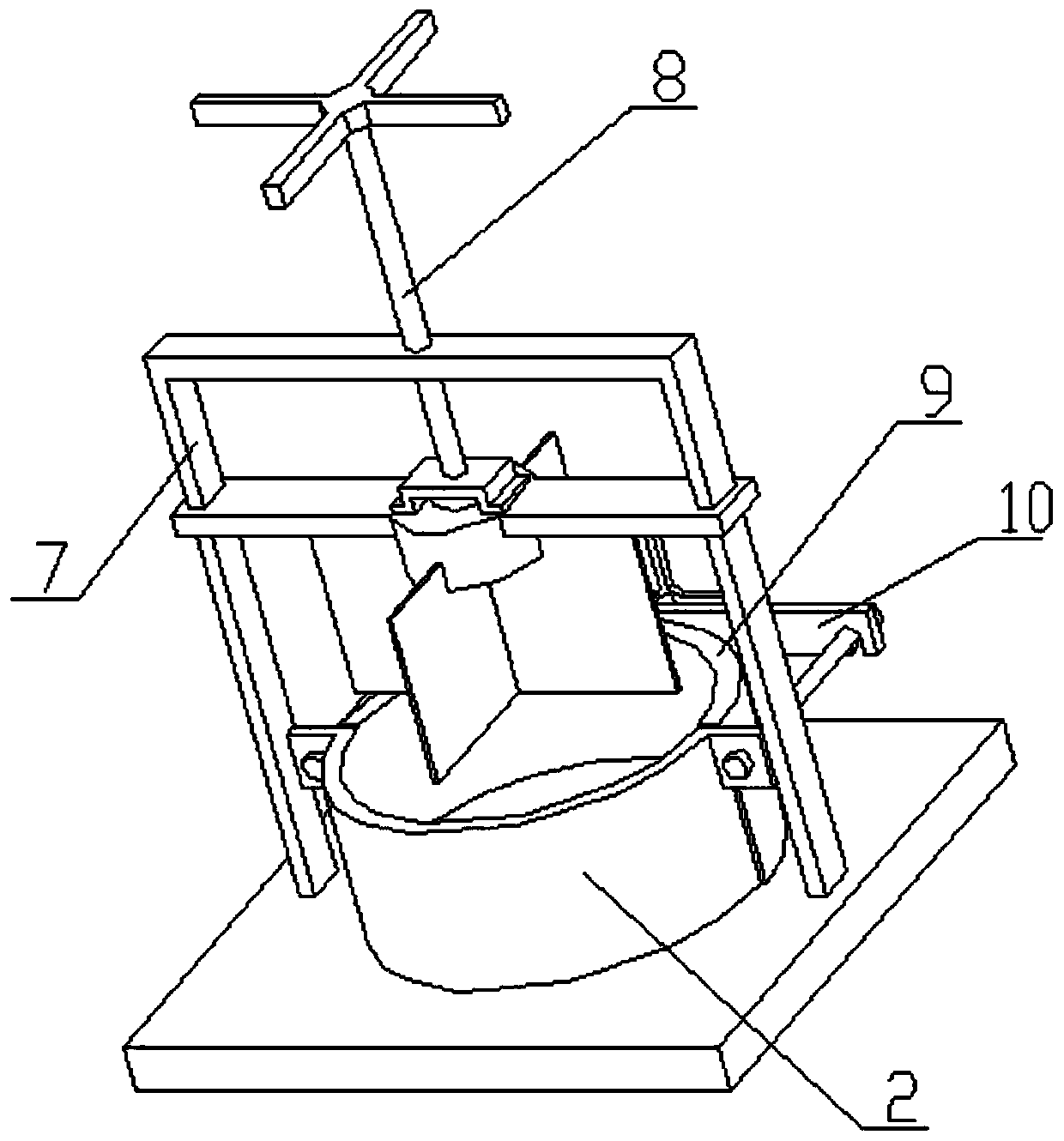

[0047] Combine below Figure 1-24 To illustrate this embodiment, the present invention relates to a living appliance, more specifically a broken soap recycling device, including a bottom plate 1, a soap base 2, a pressing cylinder 3, a rotating frame I4, a rotating frame II5, a pressing Device 6, screw hole plate 7, cutting device 8, cutting cylinder 9 and soap base fastening device 10, the device can compact and cut the leftover broken soap to achieve the effect of waste reuse.

[0048] The soap bottom bracket 2 includes an arc side baffle 2-1, a baffle I 2-2, an ear plate 2-3, a stretch bar 2-4, a baffle II 2-5, a circular bottom bracket 2-6, a convex Circle 2-7, card rib 2-8, pressure ring 2-9 and card rib groove 2-10, the cross section of arc side baffle 2-1 is semicircle, the lower end of arc side baffle 2-1 A circular bottom support 2-6 is welded, and a convex circle 2-7 is welded in the middle of the circular bottom support 2-6, and a card edge 2-8 is symmetrically wel...

specific Embodiment approach 2

[0060] Combine below Figure 1-24 This embodiment will be described, and this embodiment will further describe Embodiment 1. The threaded hole III 7 - 1 is coaxial with the cutting cylinder 9 .

[0061] Specific implementation mode two:

[0062] Combine below Figure 1-24 This embodiment will be described. This embodiment will further describe the first embodiment. The length of the spacer 4-2 is equal to the width of the middle rib 3-5.

[0063] The working principle of a broken soap recycling device of the present invention: the rotating frame I4 and the rotating frame II5 are usually placed on the rotating frame placing plate 3-3, and when the crushed soap is pressed, the pressing ring 2-9 is removed, and the Place the net cloth on the circle 2-7, install the pressure ring 2-9 on the convex circle 2-7, and insert the card edge groove 2-10 quasi-card edge 2-8 on the pressure ring 2-9 into the convex circle 2 -7, then stagger the card edge 2-8 and the card edge groove 2-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com