A kind of microbial fermented cold granulated feed

A technology of microbial fermentation and cold granulation, which is applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problems of great influence on feed quality, difficulty in environmental friendly feed, and difficulty in improving feed quality. To achieve the effect of improving the quality of feces, the meat is delicious and tender, and reducing the smell and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

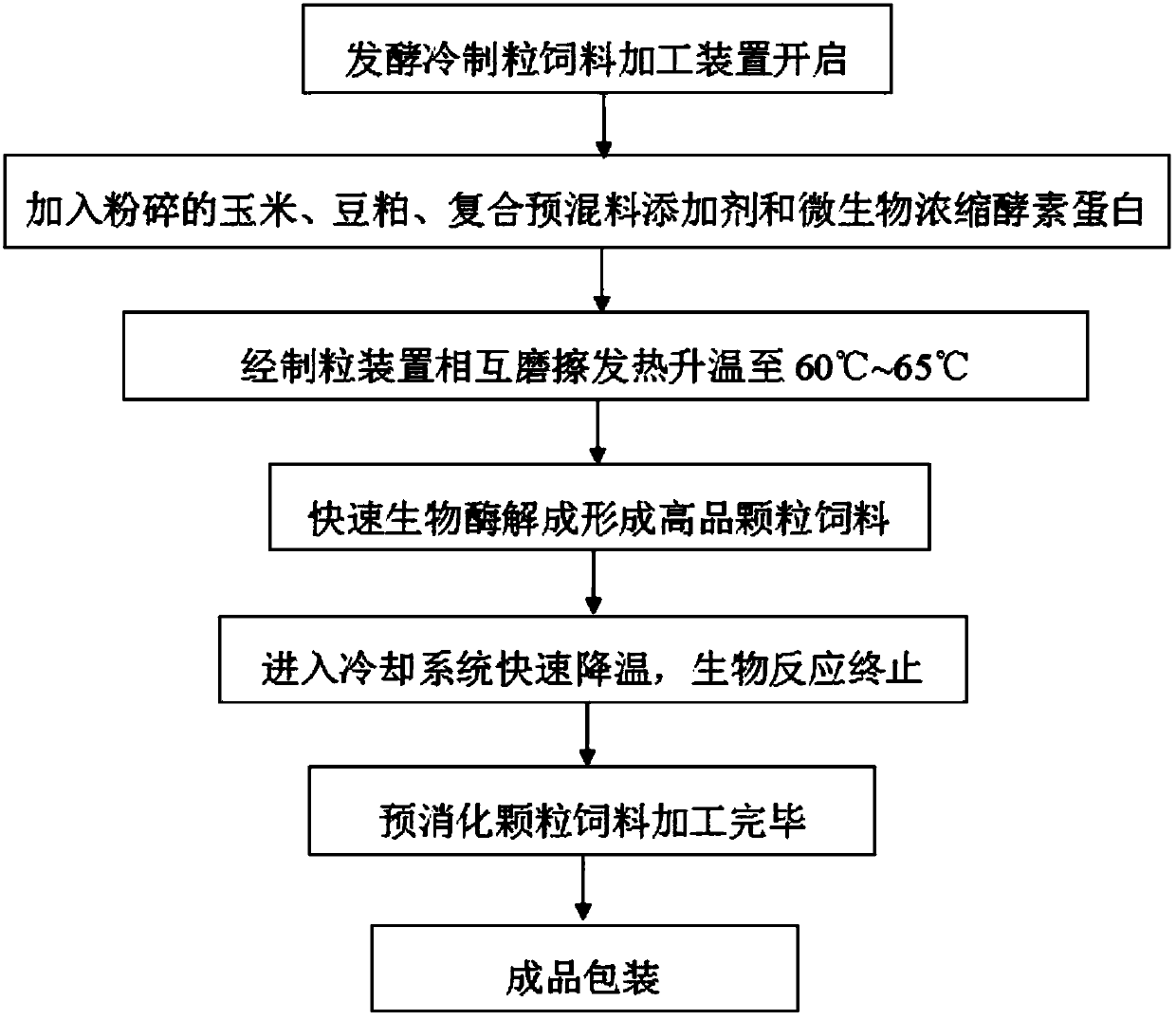

Method used

Image

Examples

Embodiment 1

[0049] Bacillus subtilis and Bacillus coagulans were multiplied and cultured at a ratio of 1:1. Add bean curd powder and diatomaceous earth to the cultured liquid bacteria, and dry at 35°C for 50 minutes at a low temperature to prepare a microbial bacterial agent. The microbial inoculum contains 10% soybean hull powder and 90% diatomaceous earth by weight ratio, and the total content of Bacillus subtilis and Bacillus coagulans contained therein is 1*10 8 CFU / g.

[0050] The feed raw material is fermented in a feed fermentation mixer by using a microbial agent to prepare microbial concentrated enzyme protein. The specific process is as follows:

[0051] Put 1000kg of soybean meal into the feed fermentation mixer that has been started, add 700kg of filtered water and stir for 3 minutes, so that the moisture content of the feed raw materials in the feed fermentation mixer is 50%; add 7.5kg of microbial agents into the above feed fermentation mixer. The frequency is 50HZ, the r...

Embodiment 2

[0055] Bacillus subtilis, Bacillus coagulans and yeast were multiplied and cultured at a ratio of 1:1:1. Add bean curd powder and diatomaceous earth to the cultured liquid bacteria, and dry at 37° C. for 45 minutes at a low temperature to prepare the first microbial agent. The first microbial agent contains 15% bean curd powder and 85% diatomaceous earth by weight ratio, and the total content of Bacillus subtilis, Bacillus coagulans and yeast contained therein is 1*10 9 CFU / g.

[0056]Bacillus subtilis and Bacillus coagulans were multiplied and cultured at a ratio of 1:3:1. Soybean skin powder and diatomaceous earth were added to the cultured liquid bacteria and dried at a low temperature of 37° C. for 45 minutes to prepare the second microbial bacterial agent. The second microbial inoculant contains 15% bean curd powder and 85% diatomaceous earth by weight ratio, and the total content of Bacillus subtilis, Bacillus coagulans and yeast contained therein is 1*10 9 CFU / g.

...

Embodiment 3

[0062] Soybean skin powder and diatomaceous earth were added to the bacterial solution containing Bacillus subtilis and dried at a low temperature of 40° C. for 50 minutes to prepare the first microbial bacterial agent. The first microbial agent contains 10% bean curd powder and 90% diatomaceous earth by weight ratio, wherein the total content of Bacillus subtilis is 1*10 8 CFU / g.

[0063] Add soybean hull powder and diatomaceous earth to the bacterial solution containing Bacillus coagulans, and dry at 40° C. for 50 minutes at low temperature to prepare the second microbial bacterial agent. The second microbial agent contains 10% bean curd powder and 90% diatomaceous earth by weight ratio, and the total content of Bacillus coagulans contained therein is 1*10 8 CFU / g.

[0064] The feed raw material is fermented in a feed fermentation mixer by using a microbial agent to prepare microbial concentrated enzyme protein. The specific process is as follows:

[0065] Put 500kg of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com