A transmission tower defect analysis device and method based on UAV patrol inspection

A technology for defect analysis and transmission poles and towers, which is applied in the directions of measuring devices, analysis materials, and optical testing for flaws/defects, etc. Safety hazards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The invention will be described in detail below with reference to the accompanying drawings and examples.

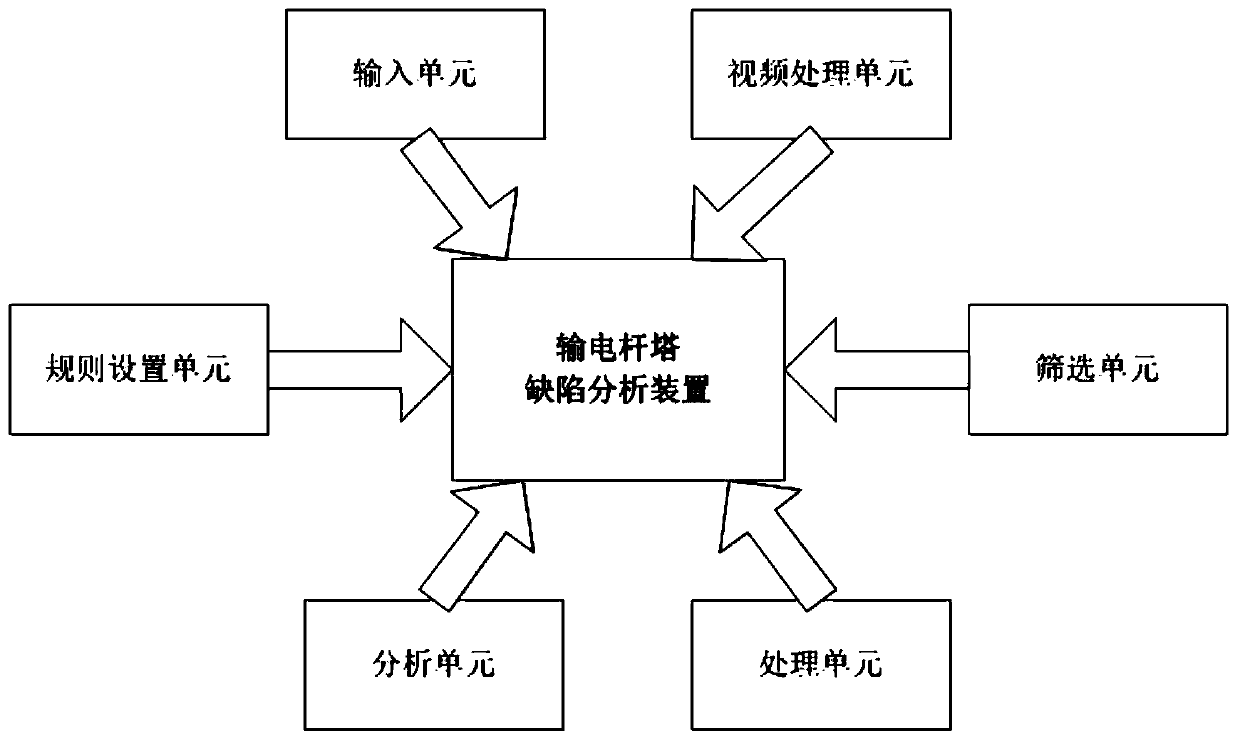

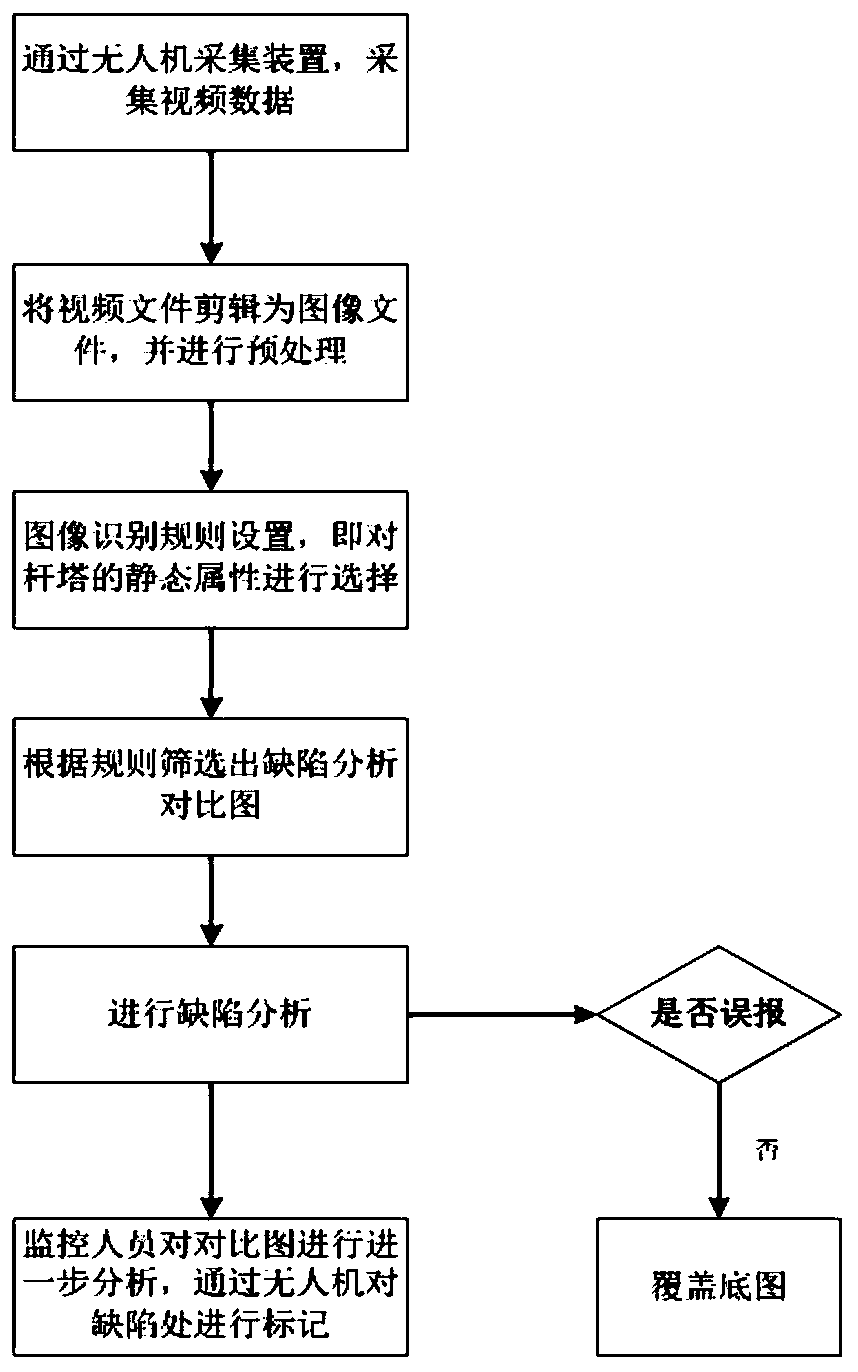

[0038] A transmission tower defect analysis device based on UAV inspection, including a UAV acquisition device and a ground workstation, the UAV acquisition device is connected to the ground workstation, characterized in that: the transmission tower defect analysis device It is mainly connected in sequence by a video acquisition unit, a video processing unit, a rule setting unit, a screening unit, an analysis unit and a processing unit.

[0039] The drone acquisition device should work in a normal weather environment without fog or rain or snow.

[0040] The video acquisition device of the drone is the SJ6000 series aerial camera.

[0041] The video acquisition device of the UAV also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com