A kind of metal rolling oil containing modified graphene oxide and preparation method thereof

A technology of metal rolling oil and oxide stone, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of difficult dispersion, weak interaction, strong intermolecular force, etc., achieve glossy surface reflectivity, and ensure cleanliness performance, high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

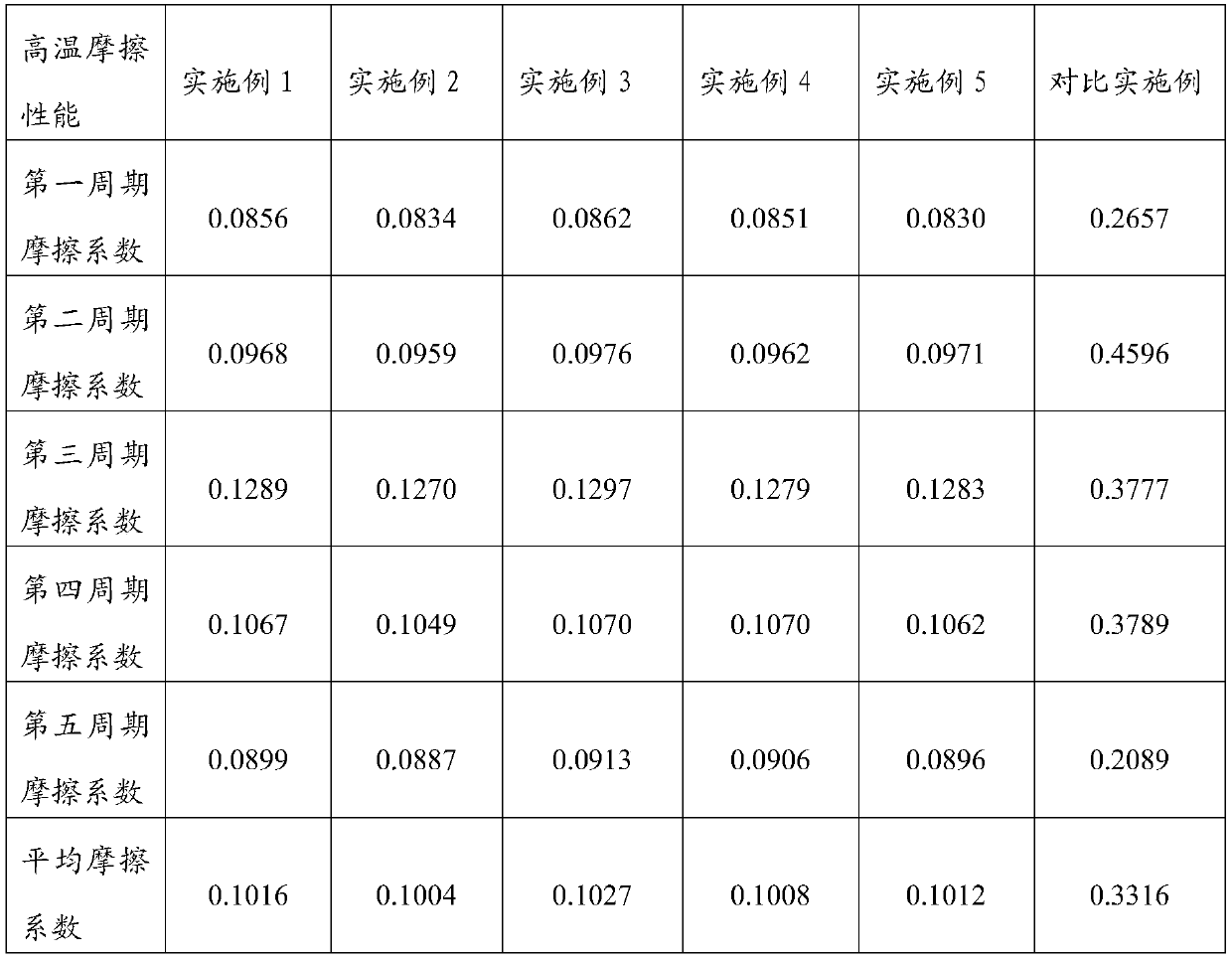

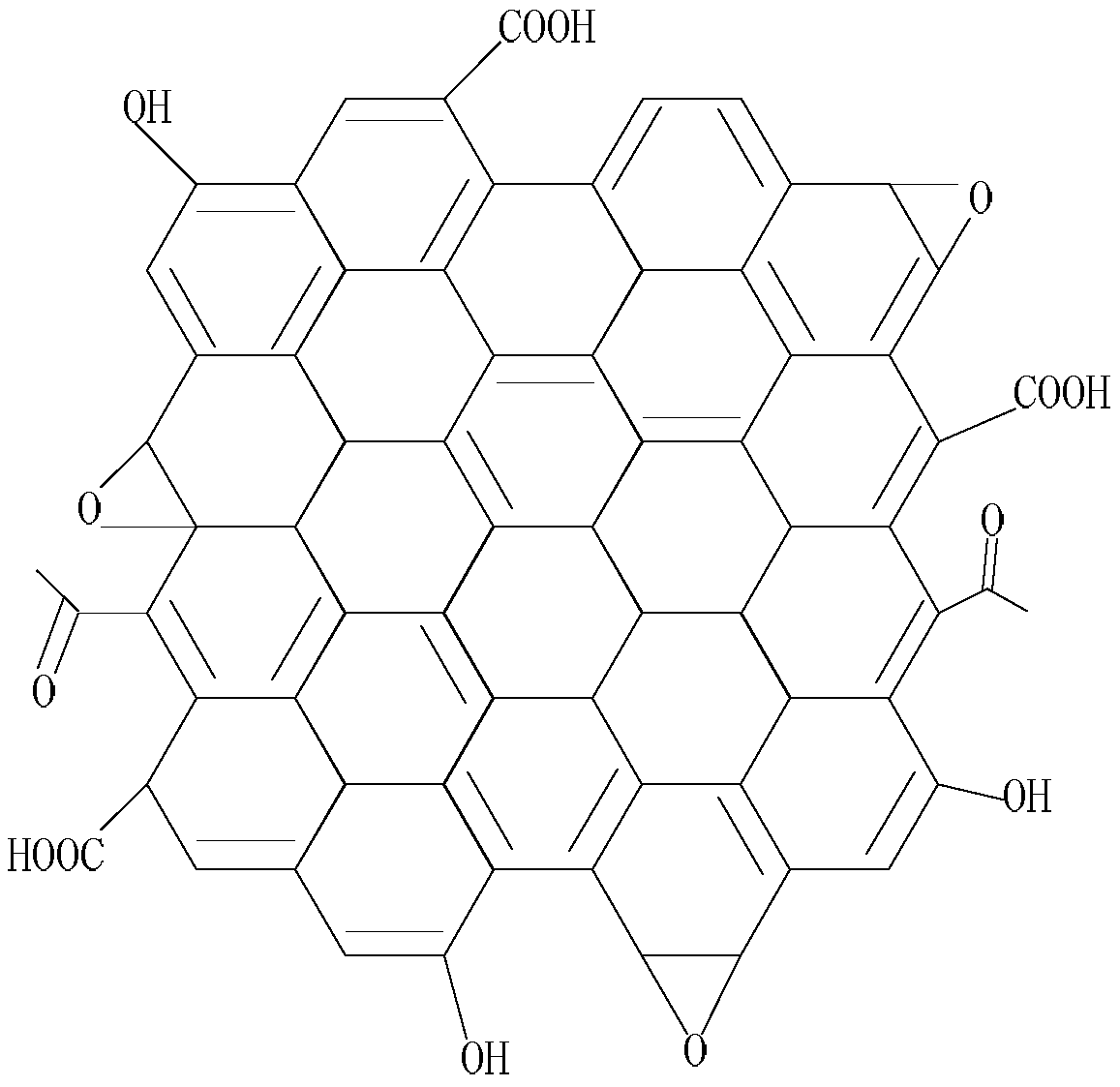

[0028] The preparation method of modified graphene oxide is: first by chemical oxidation, the graphene surface has oxygen-containing polar groups with high reactivity such as hydroxyl, carboxyl and epoxy groups, to obtain unmodified graphene oxide. Then, through the reaction of organic substances with C12-C22 alkyl groups and oxygen-containing polar groups, C12-C22 alkyl groups are grafted on the surface of unmodified graphene oxide, thereby introducing C12-C22 on the surface of graphene oxide. The grafting of alkyl groups yields modified graphene oxide. Compared with unmodified graphene oxide, modified graphene oxide has oil solubility and better dispersion in base oil, and can undergo coordination reaction with phosphorus-containing additives in base oil to form coordination compounds. Commonly used organic compounds with C12-C22 alkyl groups include oleic acid, castor oil, lauric acid, etc.

[0029] A metal rolling oil containing modified graphene oxide of the present inve...

Embodiment 1

[0045] Base oil: 51.0 parts by weight of trimethylolpropane oleate and 38.3 parts by weight of natural palm oil;

[0046] Antioxidant: 1.5 parts by weight of 2,6-di-tert-butyl-a-dimethylamino-p-cresol;

[0047] Rust inhibitor: 1.5 parts by weight of benzotriazole:

[0048] Sulfur-containing additive: 2.5 parts by weight of dialkyl polysulfide;

[0049] Auxiliary agent: 0.8 parts by weight of polyethylene glycol with a molecular weight of 1000;

[0050] Emulsifier: 0.9 parts by weight of C16-C18 fatty alcohol polyoxyethylene ether and 0.5 parts by weight of polyoxypropylene oxide glycerol ether;

[0051] Phosphorus-containing additives: 0.5 parts by weight of alkylamine phosphate and 0.5 parts by weight of oleyl alcohol polyoxyethylene phosphate;

[0052] Modified graphene oxide 2.0 parts by weight;

[0053] The weight ratio of the phosphorus-containing additive to the modified graphene oxide is 1:2. Modified graphene oxide surface grafted with castor oil.

Embodiment 2

[0055] Base oil: 45.0 parts by weight of tetraester of pentaerythritol coconut oil / oleic acid and 42.0 parts by weight of defatted lard;

[0056] Antioxidant: 0.8 parts by weight of dioctyl diphenylamine;

[0057] Rust inhibitor: 1.2 parts by weight of tolutriazole;

[0058] Sulfur-containing additive: 2.0 parts by weight of dodecyl polysulfur additive;

[0059] Phosphorus-containing additives: 1.5 parts by weight of alkylamine phosphate and 1.5 parts by weight of fatty alcohol polyoxyethylene phosphate;

[0060] Auxiliary agent: 0.9 parts by weight of hexanediol;

[0061] Emulsifier: α-hydrogen-ω-hydroxyl-polyoxyethylene, 1.3 parts by weight of D-sugar alcohol ether and 0.8 parts by weight of polyoxypropylene oxide ethylene glyceryl ether;

[0062] Modified graphene oxide 3.0 parts by weight.

[0063] The weight ratio of the phosphorus-containing additive to the modified graphene oxide is 1:1. Modified graphene oxide surface grafted with oleic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com