Thin silicon rubber and fabric composite product and mold pressing vulcanizing forming process thereof

A composite product, molded vulcanization technology, which is applied in the field of thin silicon rubber-fabric composite products and its molded vulcanization process, which can solve the problems that it is difficult to ensure that the fabric is evenly placed in the middle of the rubber material, and achieve strict size control and consistent shrinkage , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

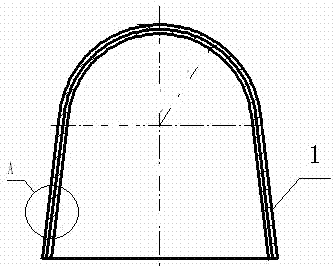

[0038] like image 3 , Figure 4 The silicone rubber-fabric composite finger cot product shown has an inner diameter of Φ26±0.1mm, a height of 28.1±0.1mm, a thickness of 1.1±0.1mm, and a fingertip spherical radius of 11±0.1mm. The skeleton fabric is placed between the inner and outer layers of silicone. The production process is as follows (1) Fabric degreasing: Soak the fabric in a stainless steel bucket filled with ethyl acetate solution for 24 hours and then take it out to dry; (2) Surface treatment: Configure 12% VTPS- Ethyl acetate solution, soak the degreased fabric in it for 2 hours and then take it out to dry; (3) Mucilage configuration: Weigh 200g of silicone rubber compound and soak it in 1000ml of gasoline for 12 hours, then stir it with a high-speed mixer , until the rubber is completely dissolved in gasoline; (4) Glue application: use a glass rod to evenly apply the glue on the fabric, dry it, cut it into a square skeleton fabric 4 of 80×80mm, and set aside; (5) ...

Embodiment 2

[0040] like Figure 5The silicon rubber-fabric composite finger cot product shown above requires an inner diameter of Φ21±0.1mm, a height of 25.8±0.1mm, a thickness of 0.8±0.1mm, and a fingertip spherical radius of 9±0.1mm. The process method is as follows (1) Fabric degreasing: Soak the fabric in a stainless steel bucket filled with ethyl acetate solution for 24 hours, then take the fabric out to dry; (2) Surface treatment: prepare 15% VTPS-ethyl acetate solution, soak the degreased fabric in it for 2 hours Take out the fabric to dry after 1 hour; (3) Glue configuration: Weigh 200g of silicone rubber compound and soak it in 1000ml of gasoline for 12 hours, then stir it with a high-speed mixer until the rubber is completely dissolved in gasoline; (4) Glue application: apply the glue evenly on the fabric with a glass rod, dry it, cut it into 70×70mm squares, and set it aside; (5) Silica gel preforming: weigh 1.6g of silica gel compound, place it at a height of 0.15 Put two pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com