Method for preparing enzyme powder

A technology of enzyme powder and ultrafine pulverization, applied in the direction of food science, etc., can solve the problems of increasing the cost of sewage discharge, harmful microbial pollution, high cost, etc., achieve high nutritional value and health care, improve antioxidant capacity, and shorten the production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

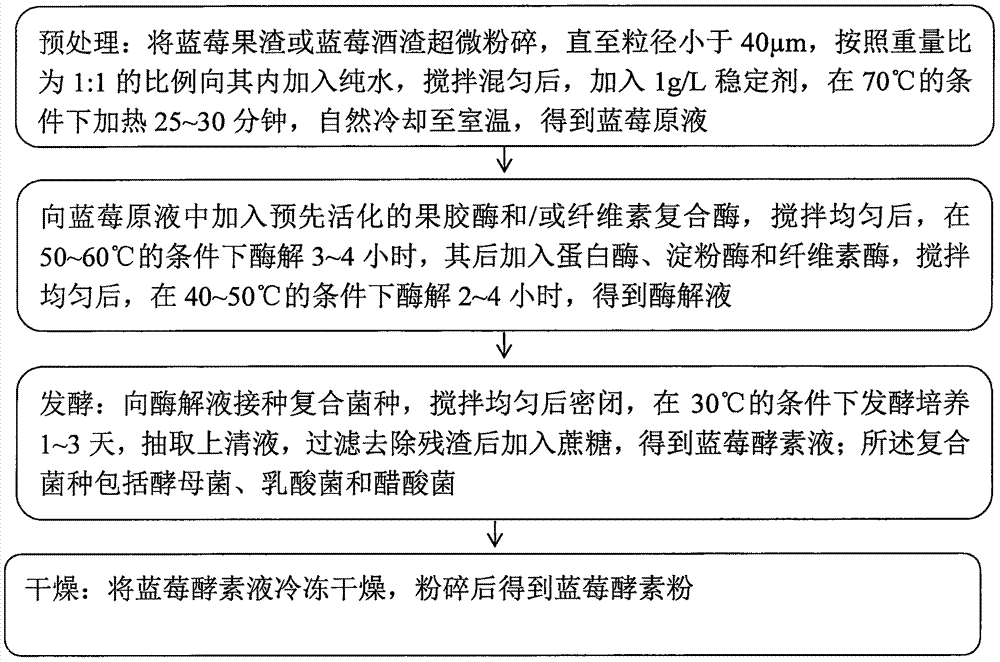

[0027] The method for preparing ferment powder that the present invention proposes, comprises the following steps:

[0028] (1) Pretreatment: Superfinely pulverize blueberry pomace or blueberry wine residue until the particle size is less than 40 μm, add pure water into it according to the ratio of 1:1 by weight, stir and mix well, add 1g / L to stabilize agent,; heated under the condition of 70 ℃ for 25 minutes, naturally cooled to room temperature, to obtain the blueberry stock solution; the stabilizer is any of sodium citrate, potassium citrate, sodium erythorbate, potassium erythorbate, chitosan A sort of;

[0029] (2) Enzymolysis: Add pre-activated pectinase and / or cellulose compound enzyme to the blueberry stock solution obtained in step (1), stir evenly, enzymolyze at 50°C for 3 hours, and then add protease , amylase and cellulase, after stirring evenly, enzymolyze at 40°C for 2 hours to obtain an enzymatic solution; the pectinase is polygalacturonase, pectin lyase and p...

Embodiment 2

[0033] The method for preparing ferment powder that the present invention proposes, comprises the following steps:

[0034] (1) Pretreatment: Superfinely pulverize blueberry pomace or blueberry wine residue until the particle size is less than 40 μm, add pure water into it according to the ratio of 1:1 by weight, stir and mix well, add 1g / L to stabilize agent,; heated at 70°C for 30 minutes, cooled naturally to room temperature to obtain blueberry stock solution; the stabilizer is any of sodium citrate, potassium citrate, sodium erythorbate, potassium erythorbate, chitosan A sort of;

[0035] (2) Enzymolysis: Add pre-activated pectinase and / or cellulose compound enzyme to the blueberry stock solution obtained in step (1), stir evenly, enzymolyze at 60°C for 4 hours, and then add protease , amylase and cellulase, after stirring evenly, enzymolyze under the condition of 50 ℃ for 4 hours to obtain the enzymolysis solution; the pectinase is polygalacturonase, pectin lyase and pec...

Embodiment 3

[0039] The method for preparing ferment powder that the present invention proposes, comprises the following steps:

[0040] (1) Pretreatment: Superfinely pulverize blueberry pomace or blueberry wine residue until the particle size is less than 40 μm, add pure water into it according to the ratio of 1:1 by weight, stir and mix well, add 1g / L to stabilize agent,; heated at 70°C for 30 minutes, cooled naturally to room temperature to obtain blueberry stock solution; the stabilizer is any of sodium citrate, potassium citrate, sodium erythorbate, potassium erythorbate, chitosan A sort of;

[0041] (2) Enzymolysis: Add pre-activated pectinase and / or cellulose compound enzyme to the blueberry stock solution obtained in step (1), stir evenly, enzymolyze at 60°C for 3 hours, and then add protease , amylase and cellulase, after stirring evenly, enzymolyze under the condition of 50 ℃ for 3 hours to obtain the enzymolysis solution; the pectinase is polygalacturonase, pectin lyase and pec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com