Internal and external double microring resonator structure

A micro-ring resonator, outer ring technology, applied in the direction of instruments, optical waveguides, optics, etc., to achieve flat resonance peaks, easy to implement, and improve the effect of resonance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

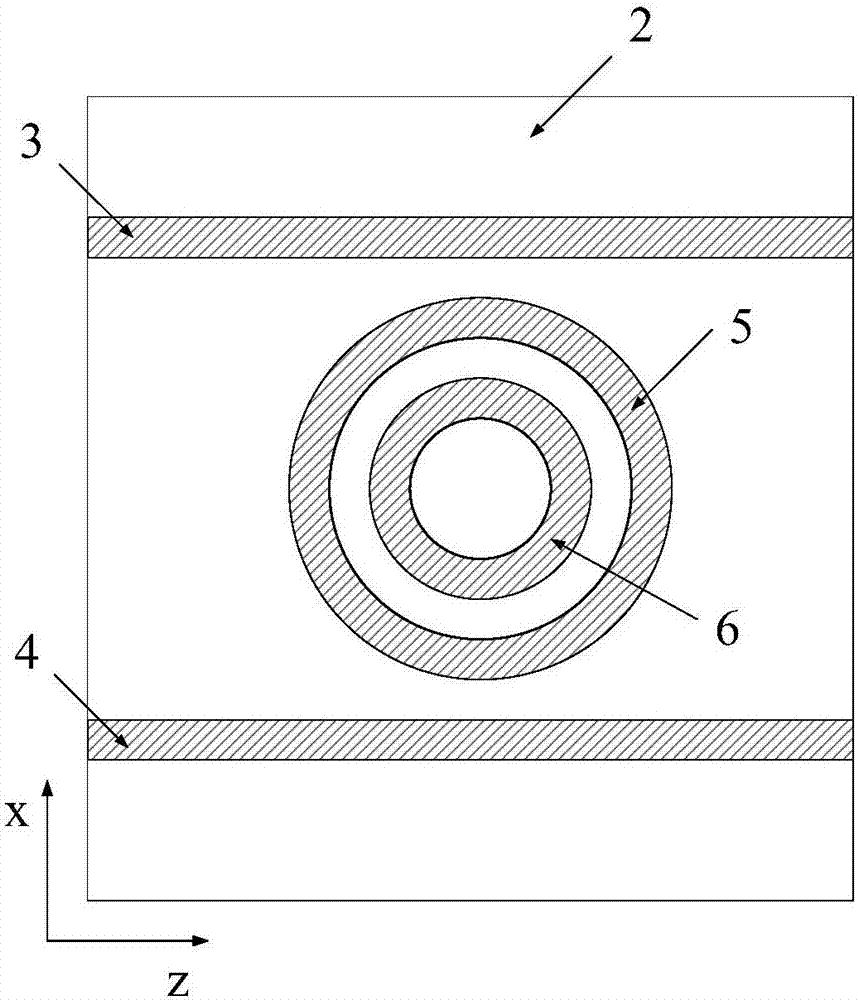

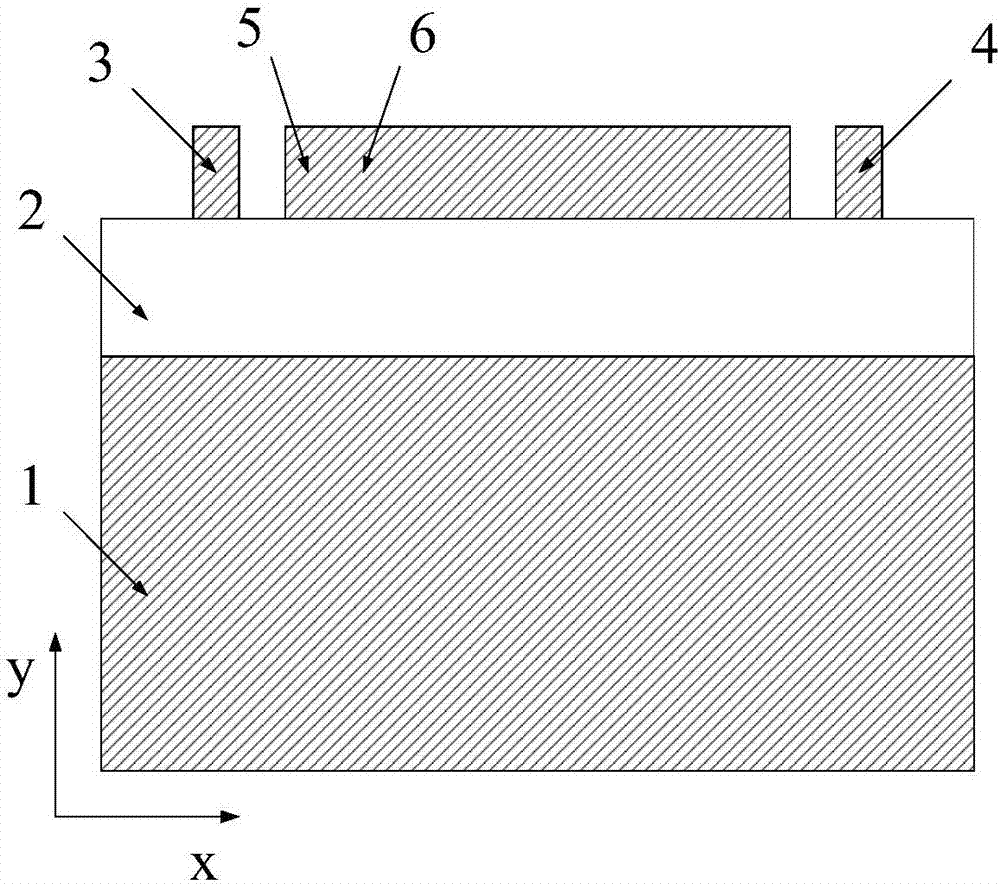

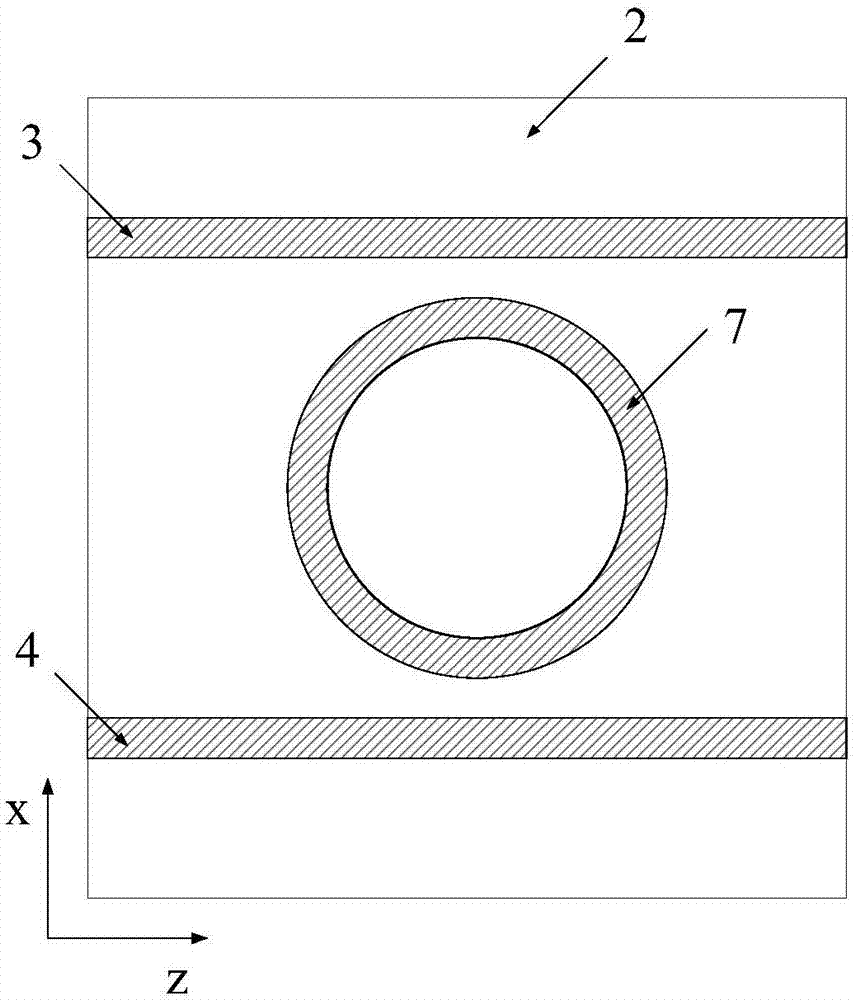

[0026] The present invention has an inner and outer double microring resonator structure, such as figure 1 with figure 2 As shown, including N-Sub type substrate 1, the top of N-Sub type substrate 1 is provided with SiO 2 Buried layer 2, in SiO 2 The two sides of the top of the buried layer are respectively provided with an upper straight waveguide 3 and a lower straight waveguide 4, and the SiO 2 An outer ring waveguide 5 and an inner ring waveguide 6 are respectively arranged in the middle of the top of the buried layer.

[0027] An inner and outer double microring resonator structure of the present invention is mainly composed of silicon material:

[0028] The doping concentration of N-Sub substrate 1 is 1×10 14 cm -3 ~1×10 15 cm -3 , the dopant is P ions; the height of the N-Sub substrate 1 is 100 μm˜300 μm, and the width is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com