Lower portion laminate prefabricated hybrid tower frame of wind power generator

A technology for wind turbines and hybrid towers, which is used in wind power generation, engine manufacturing, and assembly of wind turbines, can solve problems such as affecting the normal operation of the unit, large tower vibration, and poor economy, achieving good fatigue life and reducing hoisting. requirements, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

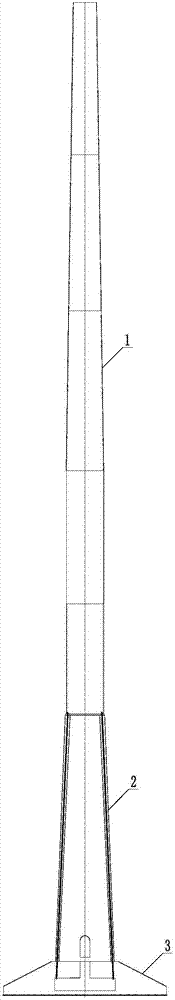

[0022] Example 1, Figure 1-Figure 6 As shown, the lower part of the wind turbine unit proposed by the present invention is a prefabricated hybrid tower.

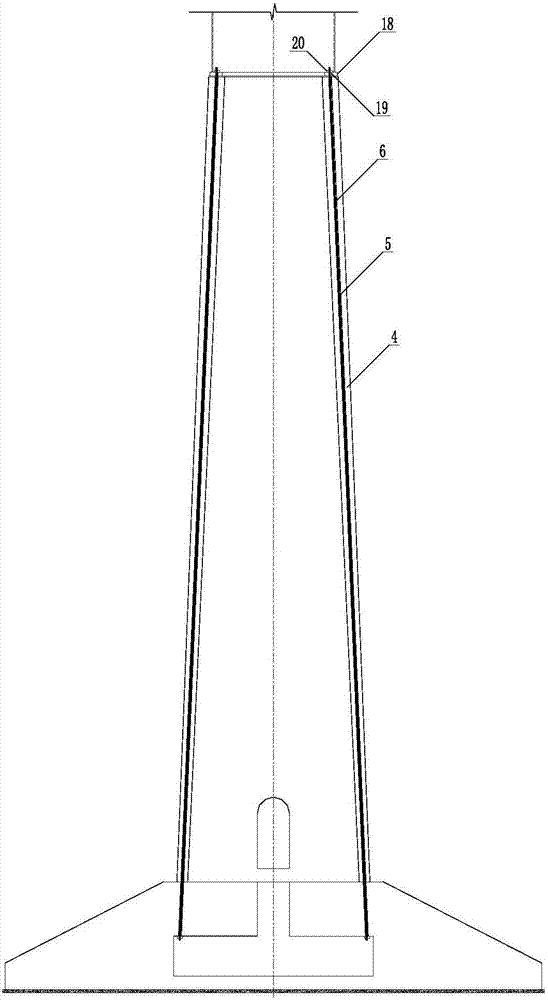

[0023] The present invention proposes a prefabricated hybrid tower in the lower section of the wind turbine, and the mixed tower is composed of an upper steel cylinder section 1, a lower section prefabricated prestressed concrete section 2 and a foundation 3, wherein:

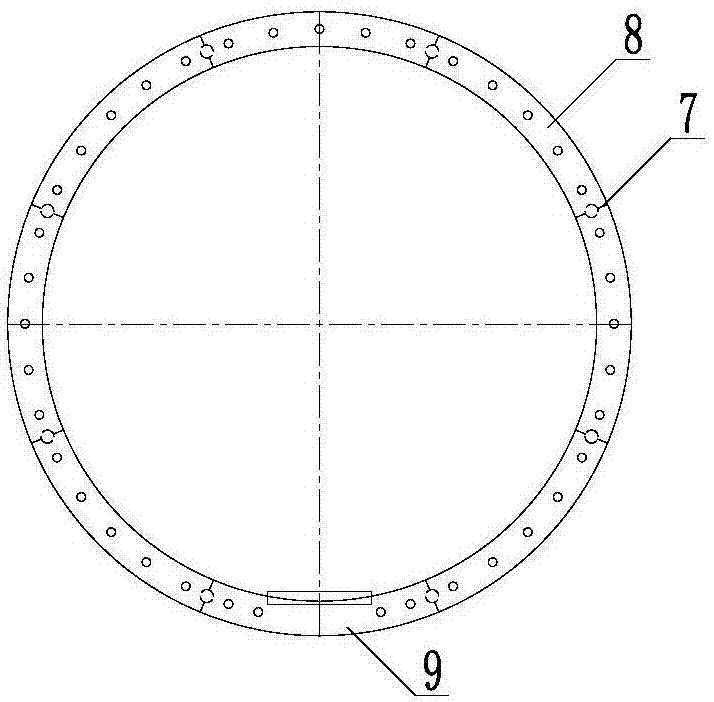

[0024] The prefabricated prestressed concrete section 2 of the lower part is composed of a reinforced concrete cylinder wall 4 , reserved tunnels 5 and vertical prestressed cables 6 . The reinforced concrete cylinder wall 4 is prefabricated in pieces, and the reinforced concrete cylinder wall 4 is equally divided into several standard units 8 and a door frame unit 9 by longitudinal joints 7 .

[0025] The inner wall of the reinforced concrete cylinder wall 4 and the edges of the longitudinal joints 7 are embedded with flanges 10 at regular intervals, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com