A kind of fragrant cigarette paper, its preparation method and application

A technology for cigarette paper and sheet cigarettes is applied in the field of moisturizing cigarette paper, and in the field of preparation thereof, it can solve the problems such as inability to modify the aroma of cigarettes to enhance the original flavor of tobacco, negative effects on the sensory quality of cigarette smoke, and single application method of moisturizing agent, and the like, To achieve the effect of shortening the crushing time, convenient transportation and use, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: The preparation of flavoring cigarette paper includes the following three steps, which can be carried out in any order or simultaneously.

[0026] (1) C2F sheet tobacco (Yunnan Yuxi tobacco raw material) and HTMOA flue-cured tobacco (Brazilian tobacco raw material) were crushed and ground respectively, and the pulverized powder was extracted by ultrasonic waves, and then extracted with ether and alcohol, and then subjected to low temperature (-30 ° C ~ -40°C) vacuum (2-8 Pa) and freeze-dried to obtain powdered tobacco extract. According to the mass ratio of C2F (Yuxi tobacco raw material in Yunnan) and HTMOA flue-cured tobacco (Brazilian tobacco raw material) extract mass ratio is 0.8kg:0.4kg, then add the tobacco extract into the water and mix evenly, at 0℃~40℃ Spray evenly onto the inner surface of 1t of cigarette paper.

[0027] (2) After dissolving 1 kg of potassium sodium tartrate as a combustion aid, add 1 kg of N-caproylglucosamine and stir evenly, an...

Embodiment 2

[0029] Example 2: The preparation of flavoring cigarette paper includes the following three steps, which can be carried out in any order or simultaneously.

[0030] (1) The sheet tobacco C1F (Yunnan Yuxi tobacco raw material) and HTMOB flue-cured tobacco (Brazilian tobacco raw material) were pulverized and ground respectively, and the pulverized powder was extracted by ultrasonic waves, and then extracted with ether and alcohol, and then subjected to low temperature (-30 ° C ~ -40°C) vacuum (2-8 Pa) and freeze-dried to obtain powdered tobacco extract. Compound according to the mass ratio of C1F (Yunnan Yuxi tobacco raw material) and HTMOB flue-cured tobacco (Brazilian tobacco raw material) extract at a ratio of 0.6kg:0.3kg, then add the tobacco extract to water and mix evenly, at 0℃~40℃ Spray evenly onto the inner surface of 1t of ordinary cigarette paper.

[0031] (2) After dissolving 0.5 kg of potassium sodium tartrate as a combustion enhancer, add 0.5 kg of D-glucuronic ac...

Embodiment 3

[0033] Embodiment 3: Cigarette samples are compared and evaluated for smoking

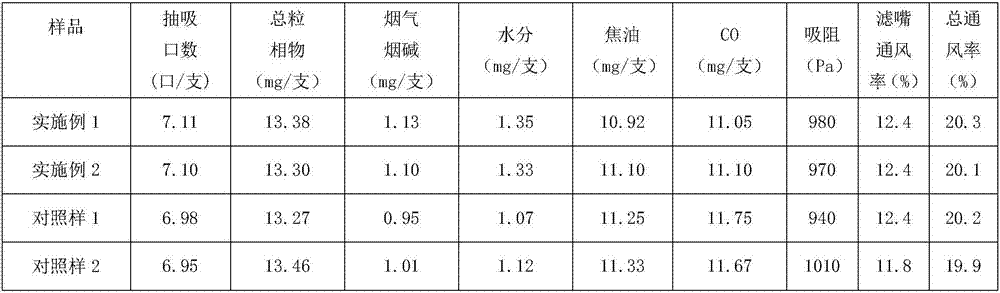

[0034] The flavoring cigarette papers prepared in Examples 1 and 2 were rolled on a cigarette machine to prepare cigarette samples. Simultaneously, conventional cigarette paper (control sample 1) and moisturizing cigarette paper (control sample 2) in the prior art were respectively rolled on the same cigarette machine to prepare cigarette samples respectively. The cigarette samples were compared and smoked, and the smoking results are shown in Table 1:

[0035] Table 1: Smoking results of sensory quality evaluation

[0036]

[0037]The comparative smoking results show that the sensory quality of the cigarette samples made from the fragrant cigarette paper prepared by the method of the present invention is obviously improved (the total score is higher) during the smoking process, especially in aspects such as aroma, pungency, moist feeling, etc. All have been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com