Processing method for repairing titanium alloy plate deformation damage

A treatment method and titanium alloy technology, which is applied in the field of titanium alloy plate processing technology, can solve the problems of large plasticity and toughness decline, internal cracks, deformation, etc. of the plate, and achieve the effect of improving the treatment effect and improving the plastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

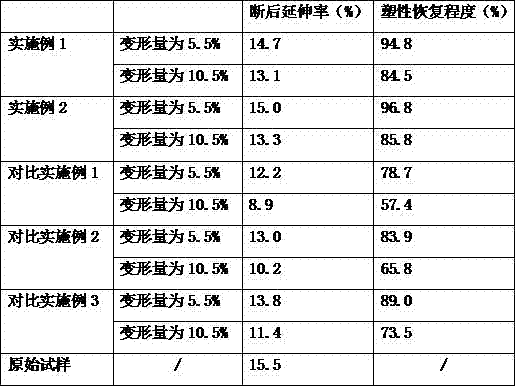

Embodiment 1

[0029] A method for repairing deformation damage of a titanium alloy plate, comprising the following steps:

[0030] (1) Surface blasting treatment:

[0031] Put the titanium alloy plate to be processed into the sandblasting machine for processing, specifically use 0.3mm stainless steel shot blasting for 10 minutes, and take out the titanium alloy plate for later use;

[0032] (2) Pickling treatment:

[0033] Soak the titanium alloy plate treated in step (1) in a hydrofluoric acid solution with a mass concentration of 3% for 8 minutes. After completion, take it out, rinse it with deionized water, and dry it for later use;

[0034] (3) Polishing treatment:

[0035] First use 100-mesh sandpaper to rough polish the titanium alloy plate after step (2), and then use 150-mesh sandpaper to fine-polish it. After completion, rinse it with deionized water and dry it for later use;

[0036] (4) Primary pulse current processing:

[0037] Apply pulse current treatment to the titanium a...

Embodiment 2

[0048] A method for repairing deformation damage of a titanium alloy plate, comprising the following steps:

[0049] (1) Surface blasting treatment:

[0050] Put the titanium alloy plate to be processed into the sandblasting machine for processing, specifically use 0.4mm stainless steel shot blasting for 14 minutes, and take out the titanium alloy plate for later use;

[0051] (2) Pickling treatment:

[0052] Soak the titanium alloy plate treated in step (1) in a hydrofluoric acid solution with a mass concentration of 3% for 12 minutes. After completion, take it out, rinse it with deionized water, and dry it for later use;

[0053] (3) Polishing treatment:

[0054] First use 100-mesh sandpaper to rough polish the titanium alloy plate after step (2), and then use 150-mesh sandpaper to fine-polish it. After completion, rinse it with deionized water and dry it for later use;

[0055] (4) Primary pulse current processing:

[0056] Apply pulse current treatment to the titanium al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com