Photocurable composition and uses of photocurable composition as varnish and colored paint

A composition and light-curing technology, applied in the field of light-curing composition and its application, polyisocyanate and polymercapto compound composition, can solve the problems of long exposure time and lack of practicability, achieve fast alkali catalysis speed, and improve curing Efficiency, does not affect the effect of the pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

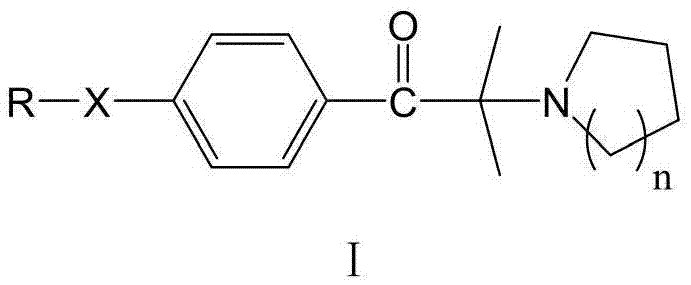

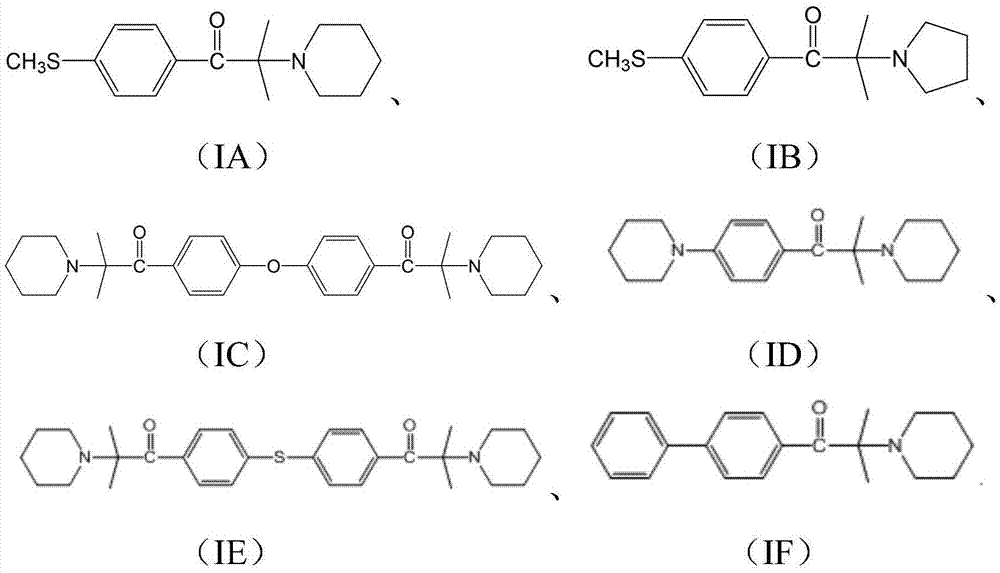

[0031] Example 1 Preparation of Photobase Generator

[0032] Compounds IA and IB were prepared according to the method described in patent EP88050; referring to this method, diphenyl ether was used as raw material instead of sulfide anisole to prepare compound IC. The H NMR spectrum data proved that the structure was correct and the melting point was 93-95°C.

Embodiment 2

[0033] Example 2 Preparation of photocurable composition

[0034] Prepare photocurable composition according to table 1 composition:

[0035] Table 1

[0036]

[0037] According to the corresponding relationship in Table 2, 5 parts of photocurable compositions were prepared

[0038] Table 2

[0039]

[0040] Among them, IHT-PI907 is a high-efficiency free radical (I) type solid photoinitiator, which is mainly used for unsaturated prepolymers (such as: acrylate) together with mono- or polyfunctional vinyl monomers and oligomers. UV curing, especially suitable for colored UV curing systems. The chemical structural formula is:

[0041] Chemical name: 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone; PLA-2 is 2-benzyl-2-dimethyl Amino-1-(3,4-dimethoxyphenyl)-1-butanone.

Embodiment 3

[0042] Embodiment 3 coating curing test

[0043] a. Prepare component A and component B respectively;

[0044] b. Mix component A and component B in proportion;

[0045] c. 100μm wire rod coating film;

[0046] d. Dry at room temperature for 3 minutes;

[0047] e. Mercury lamp, double lamp (power: 2kw) irradiation for 5s or 3s;

[0048] f. Record the time required for the paint film to fully cure after irradiation.

[0049] The test results are recorded in Table 3.

[0050] table 3

[0051]

[0052] Conclusion: the post-curing time of the composition of the present invention is significantly shorter than that of the prior art solution, and can be used in practical use completely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com