A kind of high-performance polycarboxylate slump-retaining agent and preparation method thereof

A technology of polycarboxylic acid and slump retaining agent, which is applied in the field of high-performance polycarboxylate slump retaining agent and its preparation, can solve the problems of unfavorable environmental protection, energy saving, large resource consumption, etc., and achieve good slump retaining ability and high water reducing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

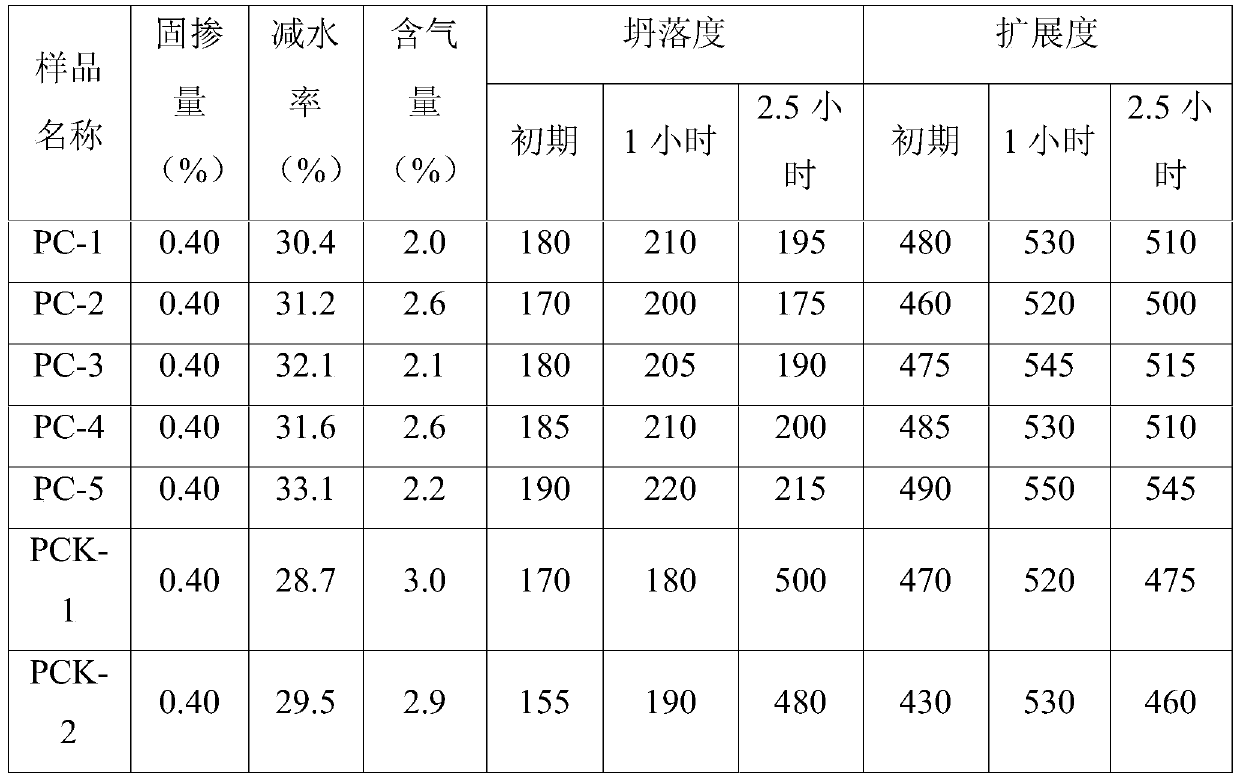

Examples

Embodiment 1

[0026] Add 300g prenol polyoxyethylene ether and 250g deionized water into a four-necked flask with a capacity of 1L, stir and dissolve, and directly add liquid C to the bottom of the reaction kettle after the dissolution is complete (the liquid C consists of 3.0g ammonium persulfate and 3.0 Concentration is 27.5% hydrogen peroxide), after ten minutes, drip A liquid and B liquid simultaneously (the described A liquid is made up of 25g acrylic acid, 35g hydroxyethyl acrylate and 30g deionized water; Described B liquid is made up of 1.6g vitamin C, 2.8g thioglycolic acid and 80g deionized water). Add liquid A dropwise for 4 hours, and add liquid B dropwise for 4.5 hours. If the system temperature exceeds 45°C during the dropwise addition, you need to turn on the cooling system to keep the temperature in the reactor at 42-45°C. After the dropwise addition, mature for 2 hours, add 169g of deionized water to adjust the obtained product to 40% solid content. That is, the finished p...

Embodiment 2

[0028] Add 300g of prenol polyoxyethylene ether, 5g of acrylic acid and 250g of deionized water into a four-neck flask with a capacity of 1L, stir and dissolve, add 3.5g of ammonium persulfate after the dissolution is complete, and add A liquid and B dropwise at the same time after ten minutes Liquid and C liquid (the A liquid is made up of 20g acrylic acid, 35g hydroxyethyl acrylate and 30g deionized water; The B liquid is made up of 1.6g vitamin C, 2.8g thioglycolic acid and 80g deionized water; C liquid is made up of 3.0g g concentration is 27.5% hydrogen peroxide and 86g deionized water). Add liquid A dropwise for 4 hours, and add liquid B and C dropwise for 4.5 hours. If the system temperature exceeds 45°C during the dropwise addition, you need to turn on the cooling system to keep the temperature in the reactor at 42-45°C. After the dropwise addition, mature for 2 hours, add 76g of deionized water to adjust the obtained product to 40% solid content. That is, the finishe...

Embodiment 3

[0030] Add 300g of prenol polyoxyethylene ether and 250g of deionized water into a four-neck flask with a capacity of 1L, stir to dissolve, add 3.5g of ammonium persulfate after the dissolution is complete, and drop A liquid, B liquid and C at the same time ten minutes later Liquid (the A liquid is made up of 25g acrylic acid, 20g hydroxyethyl acrylate, 15g methyl acrylate and 30g deionized water; the B liquid is made up of 1.6g vitamin C, 2.8g mercaptoacetic acid and 80g deionized water; C liquid Consists of 3.5g of 27.5% hydrogen peroxide and 86g of deionized water). Add liquid A dropwise for 4 hours, and add liquid B and C dropwise for 4.5 hours. If the system temperature exceeds 45°C during the dropwise addition, you need to turn on the cooling system to keep the temperature in the reactor at 42-45°C. After the dropwise addition, mature for 1.5 hours, add 83g of deionized water to adjust the obtained product to 40% solid content. That is to obtain the finished product PC-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com