Organic bacterium fertilizer taking sludge as raw material and preparation method thereof

A technology of organic bacteria and sludge, applied in organic fertilizers, sewage/sludge fertilizers, fertilization devices, etc., can solve the problems of small consumption, uneven technology, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The preparation of embodiment 1 decomposed straw

[0073] 1. Main raw materials

[0074] 1. The first microbial agent, by weight:

[0075]

[0076] Requirements for the prepared compound bacterial agent: acid protease ≥ 2000u / g, neutral protease ≥ 10000u / g, cellulase ≥ 10000u / g, and the corresponding enzyme preparation is added to the insufficient part.

[0077] Bacillus subtilis KX-1 can survive and reproduce at 2-8°C.

[0078] 2. Volcanic rock biological agents

[0079] Volcanic rock biological preparations are made of porous and large surface area structural properties of volcanic rocks, containing a large amount of silicon, potassium, sodium, iron, magnesium, aluminum, silicon, calcium, titanium, manganese, iron, nickel, cobalt and other dozens of minerals and trace elements, as well as the chelation of heavy metals, using it as a carrier, implanting a variety of beneficial microbial flora that has been verified to be harmless to humans, animals and other orga...

Embodiment 2

[0140] The preparation of embodiment 2 biofloc

[0141] Biofloc preparation includes the following steps:

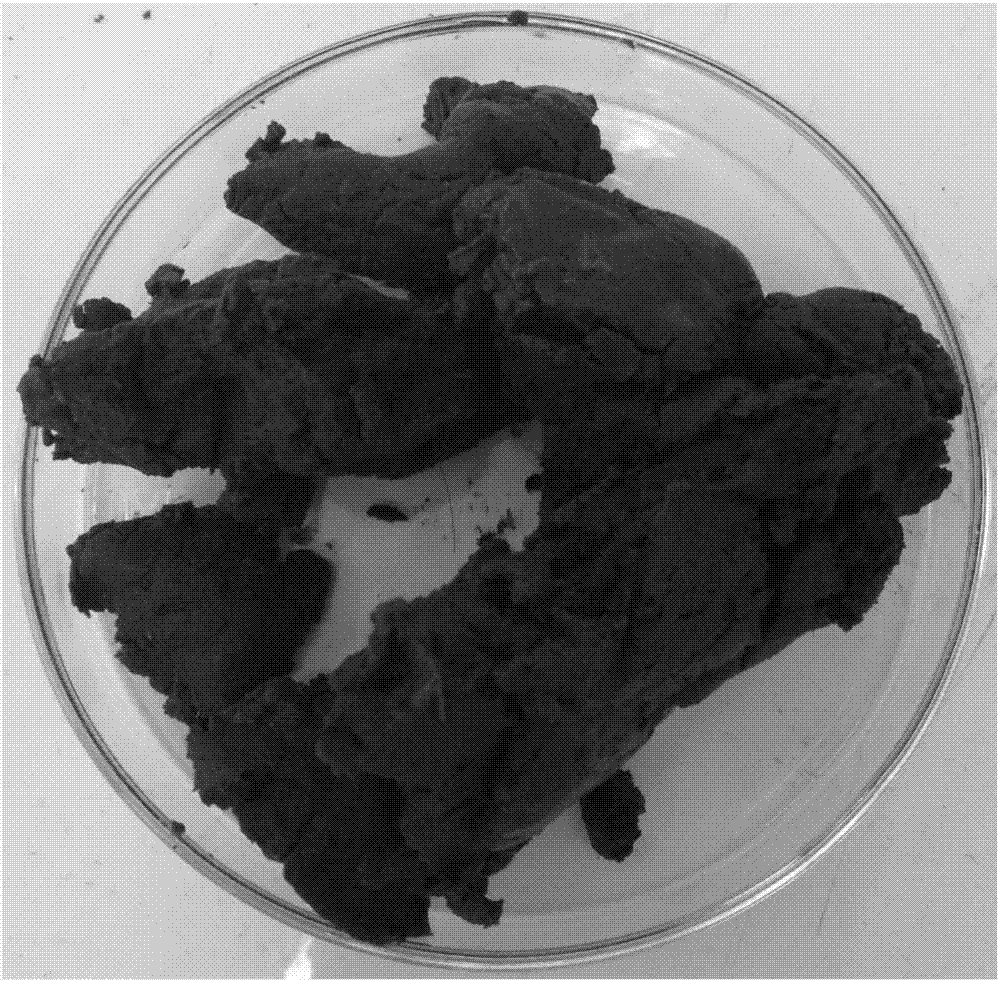

[0142] (1) The decomposed stalks obtained according to the method of Example 1 are pulverized into about 80 orders with a pulverizer to obtain decomposed stalk powder (such as figure 1 );

[0143] (2) Add 200 grams of the first microbial bacterial agent per kilogram of decomposed straw powder Add the first microbial bacterial agent to the decomposed straw powder, and then spray nitrifying bacteria and denitrifying bacteria in turn, the addition of nitrifying bacteria and denitrifying bacteria is 100ml Every kilogram of decomposed straw powder can get biofloc.

[0144] For a picture of the resulting biofloc see figure 2 .

[0145] The organic indicators of the biofloc obtained in this example and the biofloc produced by a foreign company were tested, and the results are shown in Table 4. In addition, the trace elements of the biofloc in this example were tested, and...

Embodiment 3

[0150] The preparation of embodiment 3 organic fertilizer

[0151] This example provides an organic bacterial fertilizer, in parts by weight, whose raw material formula includes 1 part of biofloc; 5 parts of sludge and 0.25 part of fermentation bacteria, wherein the biofloc is prepared according to the method in Example 2; the sludge is taken from The basic requirements for the activated sludge of the aged sludge in the urban domestic sewage treatment plant (the domestic sewage should be mainly treated by the urban sewage treatment plant (> 70%): 1. The activated sludge is selected from the aeration tank and discharged Aged sludge, and no PAC, PAM and other coagulants and flocculants were added before the filter press drying; 2. The sludge was tested for heavy metals, and the content of various heavy metals could not exceed the national standard: NY884-2012; the fermentation bacteria were A mixture composed of Bacillus subtilis KX-1 with the preservation number CCTCC NoM208057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com