A kind of 3D printer that recycles the plastic used for 3D printing and printing method thereof

A 3D printer, 3D printing technology, applied in the direction of processing and recycling, 3D object support structure, manufacturing tools, etc., can solve the problems of unrealistic equipment, inconvenient use, uneconomical, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

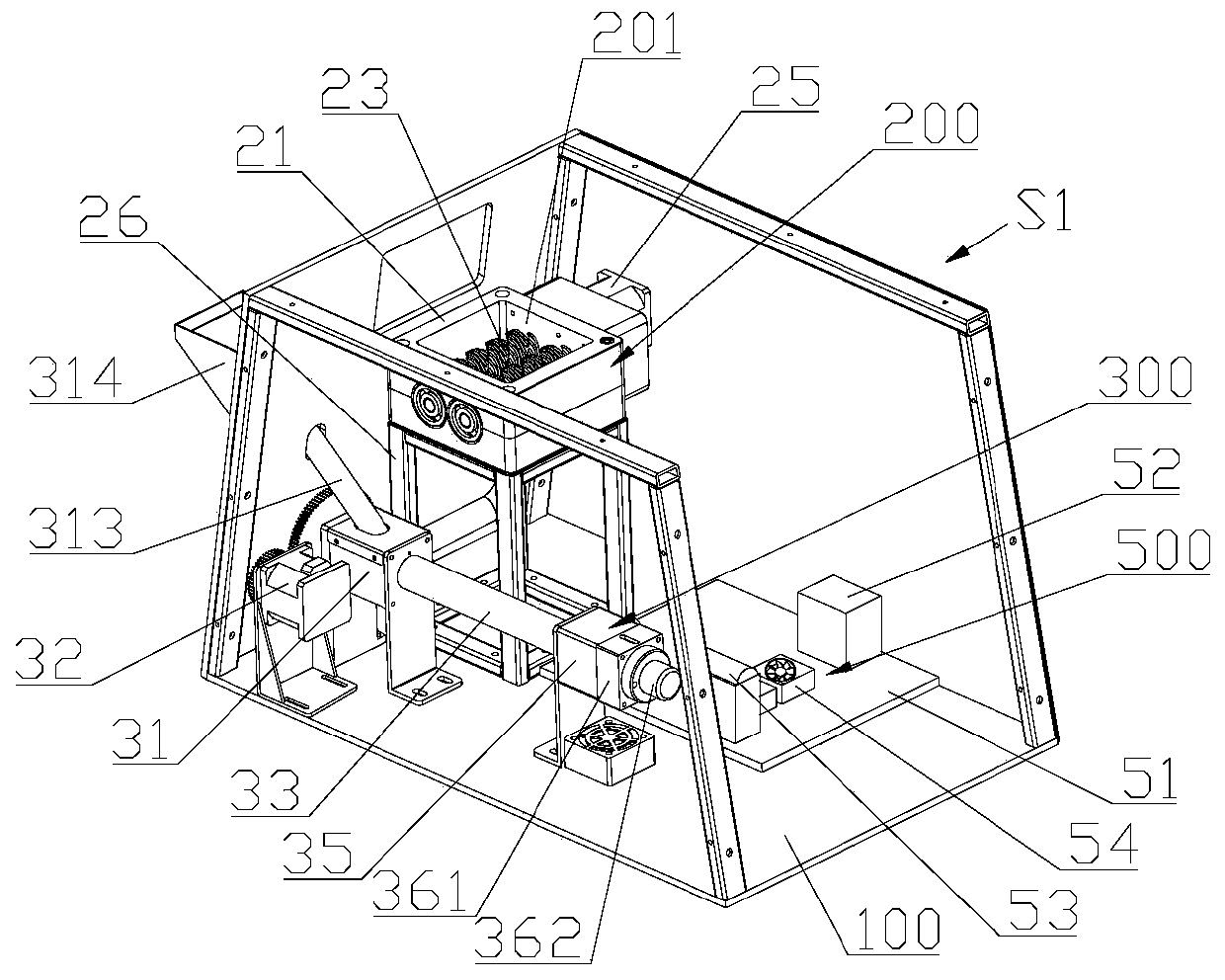

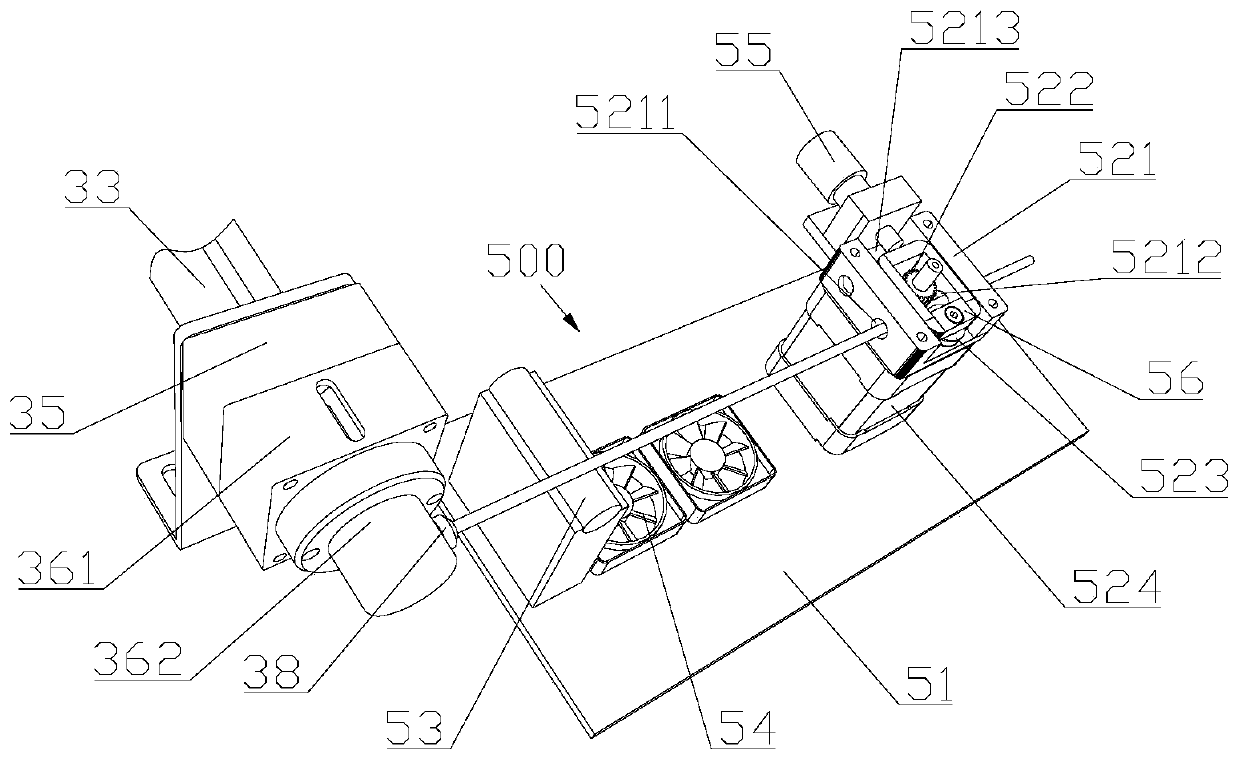

[0049] First, combine Figure 2 to Figure 4 See cooling traction assembly 500.

[0050] The cooling traction assembly 500 includes a support base plate 51 and a conveyor 52 arranged on the support base plate 51. The support base plate 51 is detachably connected to the main frame 100, so that the modular installation of the cooling traction assembly 500 can be realized. The conveyor 52 has a wire passage, The extrusion nozzle 38 is located on the same straight line as the wire passage.

[0051] Conveyor 52 comprises conveying seat 521, conveying driving wheel 522, conveying driven wheel 523 and conveying motor 524, the output shaft of conveying motor 524 passes conveying seat 521, and conveying driving wheel 522 can be directly installed on the output shaft of conveying motor 524, The conveying motor 524 drives the conveying driving wheel 522, and the conveying driven wheel 523 is rotatably connected to the conveying seat 521. A conveying gap is formed between the conveying dr...

Embodiment 2

[0071] In order to improve the heat insulation effect, this embodiment adds a cooling element on the basis of Embodiment 1, specifically as Figure 11 and Figure 12 As shown, a cooling element 37 is provided between the heat insulating element 35 and the downstream end of the feeding cylinder 33, the cooling element 37 is provided with a cooling pipe 371, and the cooling pipe 371 communicates with a water pump 372 and a water tank 373 to form a cooling cycle, and the heat insulating element 35 passes The cooling element 37 is connected with the feeding cylinder, and the cooling element 37 is provided with a cooling passage 370, and the downstream end of the feeding cylinder 33, the cooling passage 370, and the heat-insulating passage 351 communicate with the hot melt chamber in sequence. Because the cooling element 37 adopts the mode of circulating cooling, the cooling effect is relatively good, and the melting of the plastic in the feeding cylinder 33 can be avoided better. ...

Embodiment 3

[0075] The present invention also provides a printing method of the 3D printer in the above embodiment, such as figure 1 As shown, the printing device includes a printing nozzle S21, and the specific printing method includes the following steps:

[0076] Step 1, parameter preparation, input the model data file into the controller, and the controller obtains the theoretical printing speed of the printing nozzle S21 in each unit time, and the theoretical extrusion speed V of the melt extrusion component in each unit time 0 and with V 0 Real-time corresponding theoretical wire diameter D 0 ;

[0077] Step 2, put the recycled plastic into the crushed material component, and the crushed material component crushes the recycled plastic into plastic granules and transports them to the melt extrusion component;

[0078] Step 3, the printing device is preheated;

[0079] Step 4, the melting extrusion component melts the plastic particles through the melting cavity and extrudes the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com