Refrigerator reduced-pressure foaming box clamp

A box and refrigerator technology is applied in the field of refrigerator decompression foam box fixtures, which can solve the problems of leakage pressure, equipment waste, and difficulty in controlling negative pressure closed space, and achieve the advantages of increased adjustability, large flow rate, and reduced flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings.

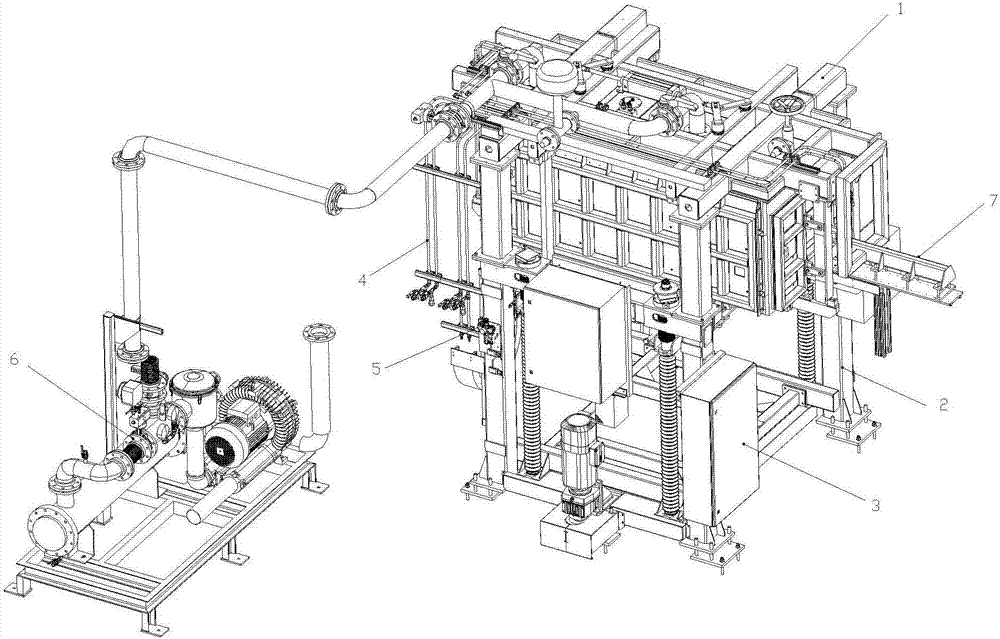

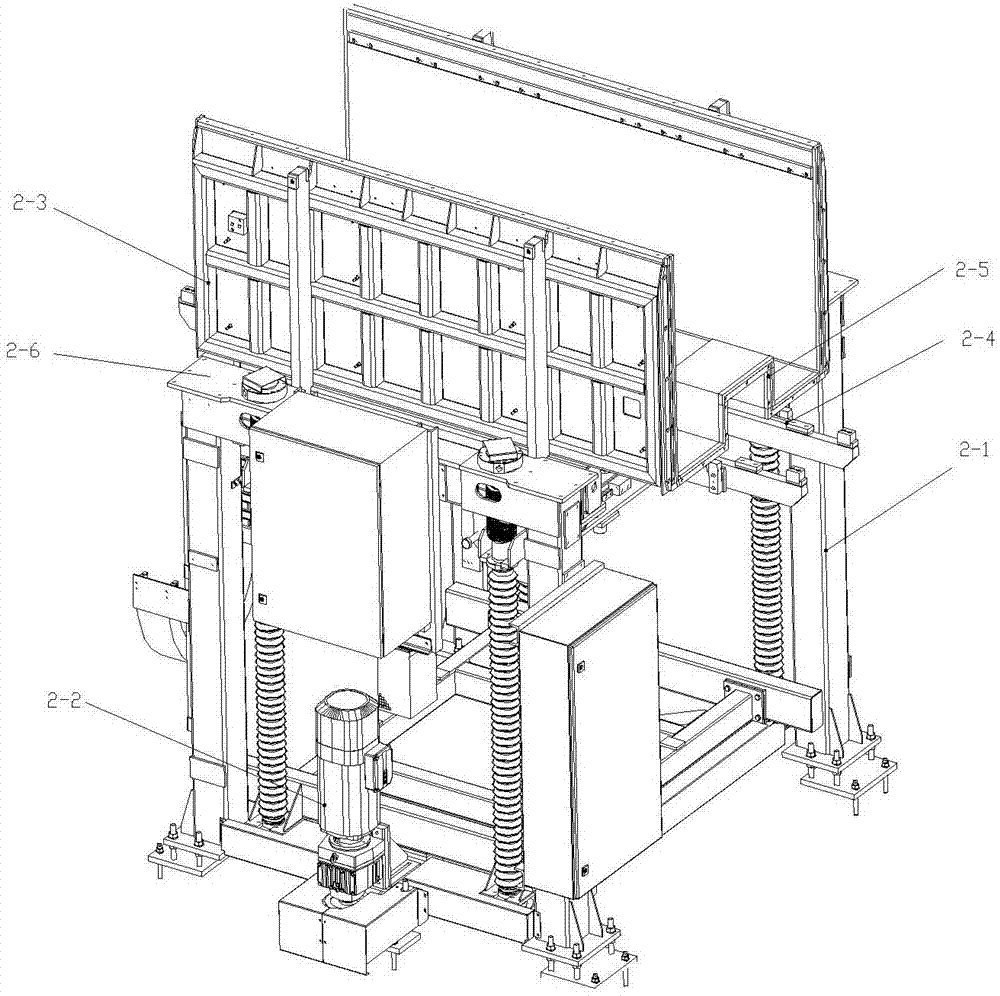

[0025] Such as Figure 1 to Figure 7 As shown, the upper assembly 1 is provided above the lower assembly 2, the pneumatic control system 5 is provided on the left side of the lower assembly 2, the front electrical control system 3 of the lower assembly 2, and the rear of the lower assembly 2 A waterway temperature control system 4 is provided on the side; a decompression and ventilation system 6 is connected above the upper assembly 1 , and a gun tip foaming mechanism 7 is provided on the front side of the upper assembly 1 .

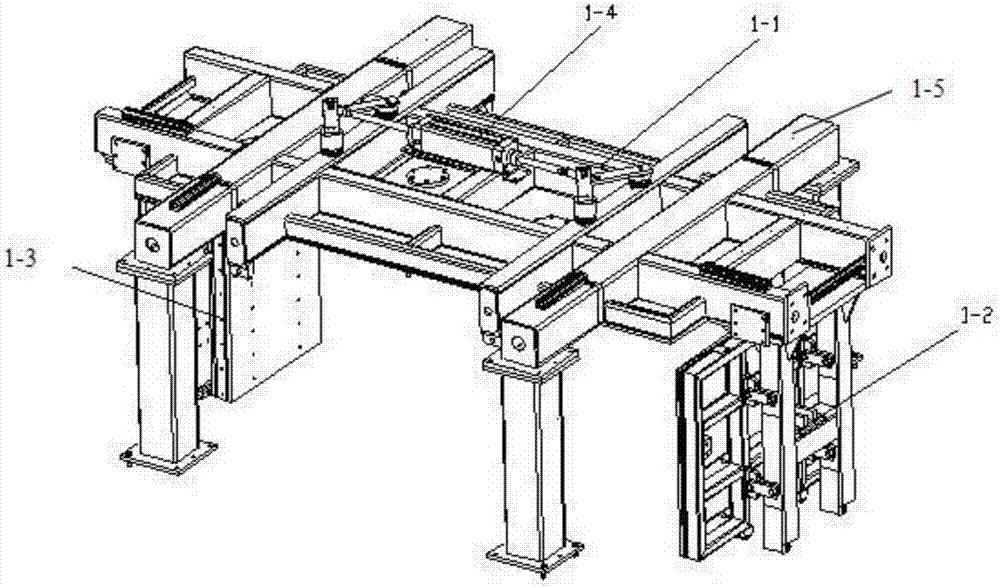

[0026] The upper assembly 1 is composed of a top plate 1-1, a front baffle 1-2, a rear baffle 1-3, a clamping system 1-4 and a top frame 1-5, and the top frame 1-5 consists of two Two door-shaped brackets are placed side by side, front and rear, left and right, a top plate 1-1 is arranged between the two door-shaped brackets, and the left and right end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com