Zero-valent-iron-pillared montmorillonite repairing material, and preparation method and applications thereof

A repair material, a technology of montmorillonite, applied in the field of zero-valent iron pillared montmorillonite repair material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a zero-valent iron pillared montmorillonite restoration material, comprising the following steps:

[0048] Step 1: Weigh 10 g of calcium-based montmorillonite and disperse it in 200 ml of 0.1M NaCl solution, stir thoroughly in a constant temperature water bath at 60°C for 2 h, after standing for 2 h, place the sodium product in a centrifuge and centrifuge Separate, discard the supernatant, add 100 ml of 0.1M NaCl solution, stir thoroughly in a constant temperature water bath at 60°C for 2 h, let it stand for 2 h, put the sodiumized product in a centrifuge for centrifugation, discard the supernatant, and then Add 50 ml of 0.1M NaCl solution, stir thoroughly in a constant temperature water bath at 60°C for 2 h, and after standing for 24 h, place the sodiumized product in a centrifuge for centrifugation, discard the clear liquid, wash 5 times with distilled water, and finally remove the sodium The chemical product was dried at 60°C, and then ground t...

Embodiment 2

[0054] A zero-valent iron pillared montmorillonite repair material prepared in Example 1 is used to efficiently activate permonosulfate (PMS) to remove refractory organic matter, including the following steps:

[0055] Step 1: Accurately weigh 0.4 g NaOH and 0.4 g TBBPA in turn, add water to a 100 ml volumetric flask to prepare a 4 g / L TBBPA stock solution, and accurately measure 5 mL of 4 g / L TBBPA stock solution in a 2000 mL volumetric flask Dilute to 10 mg / L TBBPA solution in the volumetric flask;

[0056] Step 2: Prepare to measure 250mL of 10 mg / L TBBPA solution in a 500mL beaker, and then accurately weigh 0.0154 g of PMS and 0.0125 g of Fe in sequence 0 -Mt in a 500 mL beaker, extract the TBBPA solution in the 5 ml beaker with a syringe every 5 min, and measure the UV-vis spectrum of TBBPA in the solution with a UV spectrophotometer; the relevant results are as follows Figure 5 As shown, the complete degradation of TBBPA can be realized within 15min;

[0057] Step 3: ...

Embodiment 3

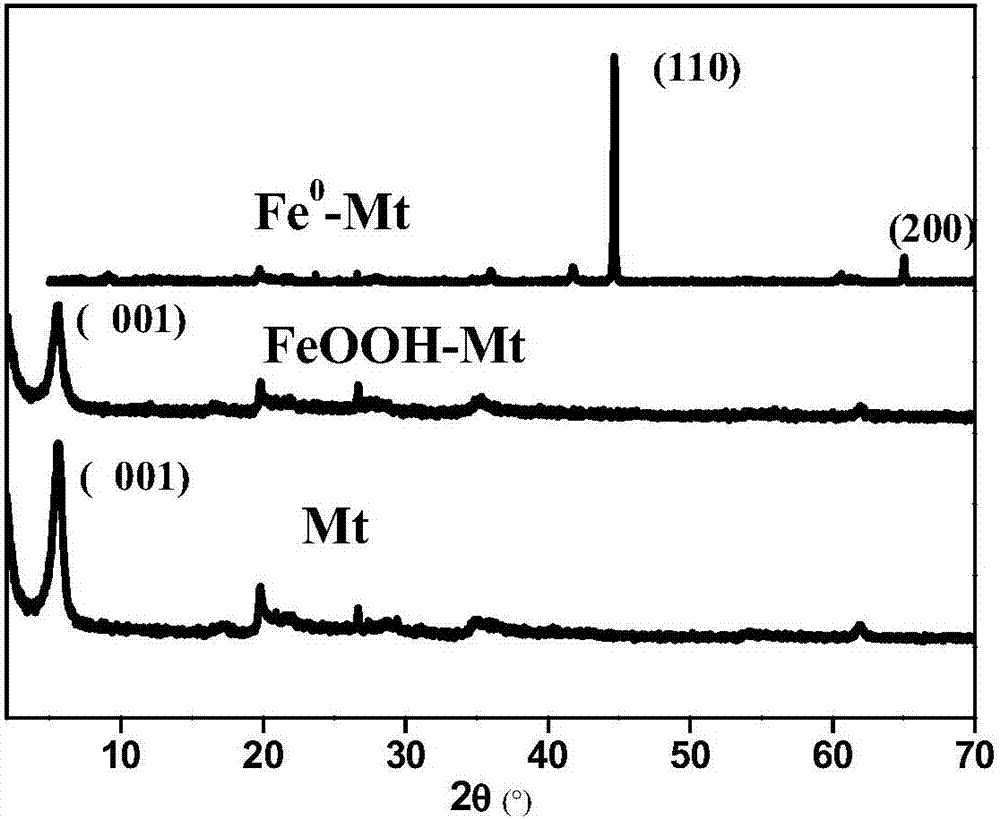

[0060] The first step: other steps are the same as in Example 1, except that in the fourth step, the hydroxyl iron pillared montmorillonite is heated to 300 °C at a heating rate of 5 min / °C in a mixed atmosphere of hydrogen and nitrogen with a volume ratio of 50:50. °C, 500 °C, 700 °C and 900 °C for 3 hours, and the reduced products were ground and sieved to obtain zero-valent iron pillared montmorillonite repair materials obtained by thermal reduction at different temperatures; compared the thermal reduction at different temperatures XRD patterns of zero-valent iron pillared montmorillonite restoration materials (such as Figure 8 shown), it was found that the characteristic peaks (110) and (200) of zero-valent iron could be observed;

[0061] Step 2: Prepare and measure 4 parts of 250 mL of 10 mg / L TBBPA solution in four 500 mL beakers, accurately weigh 4 parts of 0.0154 g of PMS in 250 mL of TBBPA solution, and then accurately weigh 0.0125 g of Fe0-Mt obtained by thermal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com