A method for preparing coded microspheres

A technology for coding microspheres and coding materials, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., to achieve the effects of being conducive to wide-scale promotion, simple preparation process and excellent coding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for preparing coded microspheres, in a specific embodiment, comprising the following steps:

[0029] (1) Mix the encoding material with the water-based oligomer, add the corresponding water-based photoinitiator to dissolve completely, and oscillate and stir evenly to form a stable suspension as the water phase;

[0030] (2) mixing and shaking the alkane solvent and emulsifier evenly to form an oil phase;

[0031] (3) drop the water phase in step (1) into the oil phase in the stirring step (2), the volume of the oil phase is 20-30 times the volume of the water phase, drop Continue to stir until the suspension system is uniformly suspended after the addition, and continuously irradiate the suspension system with ultraviolet light;

[0032] (4) After the cured product is washed several times, the microspheres with the target particle size are screened out, and the coded microspheres are obtained after drying.

[0033] In some prefe...

Embodiment 1

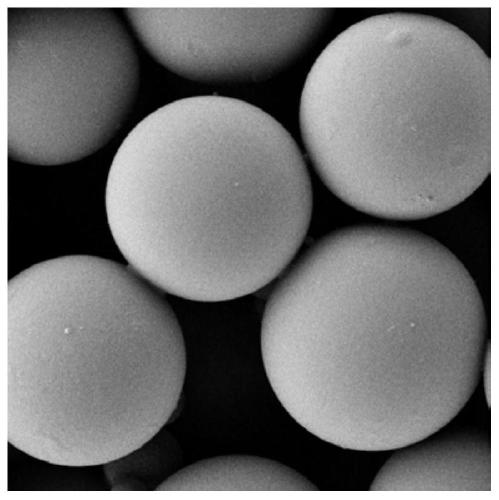

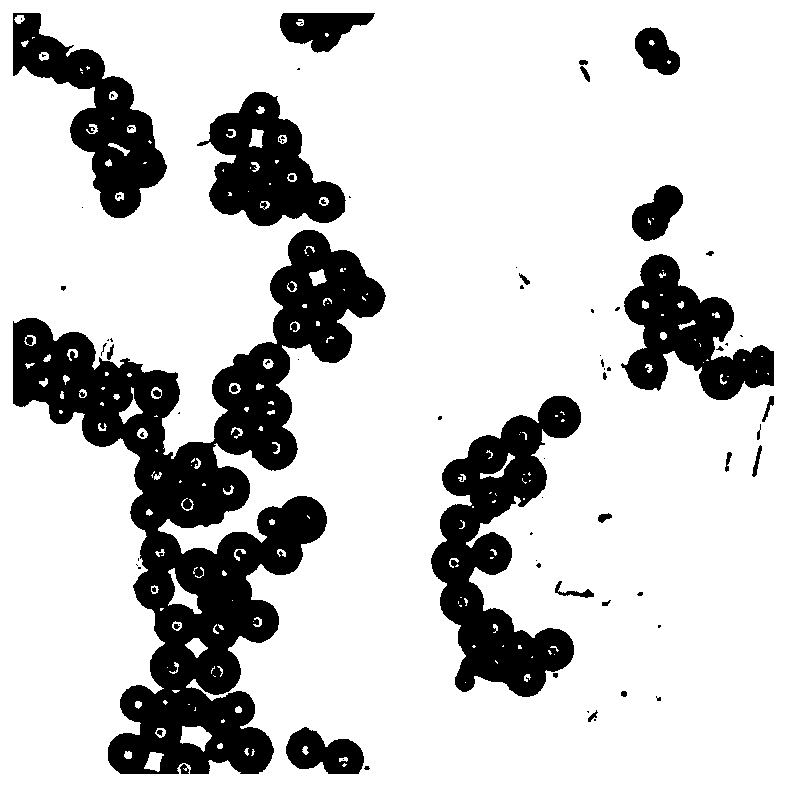

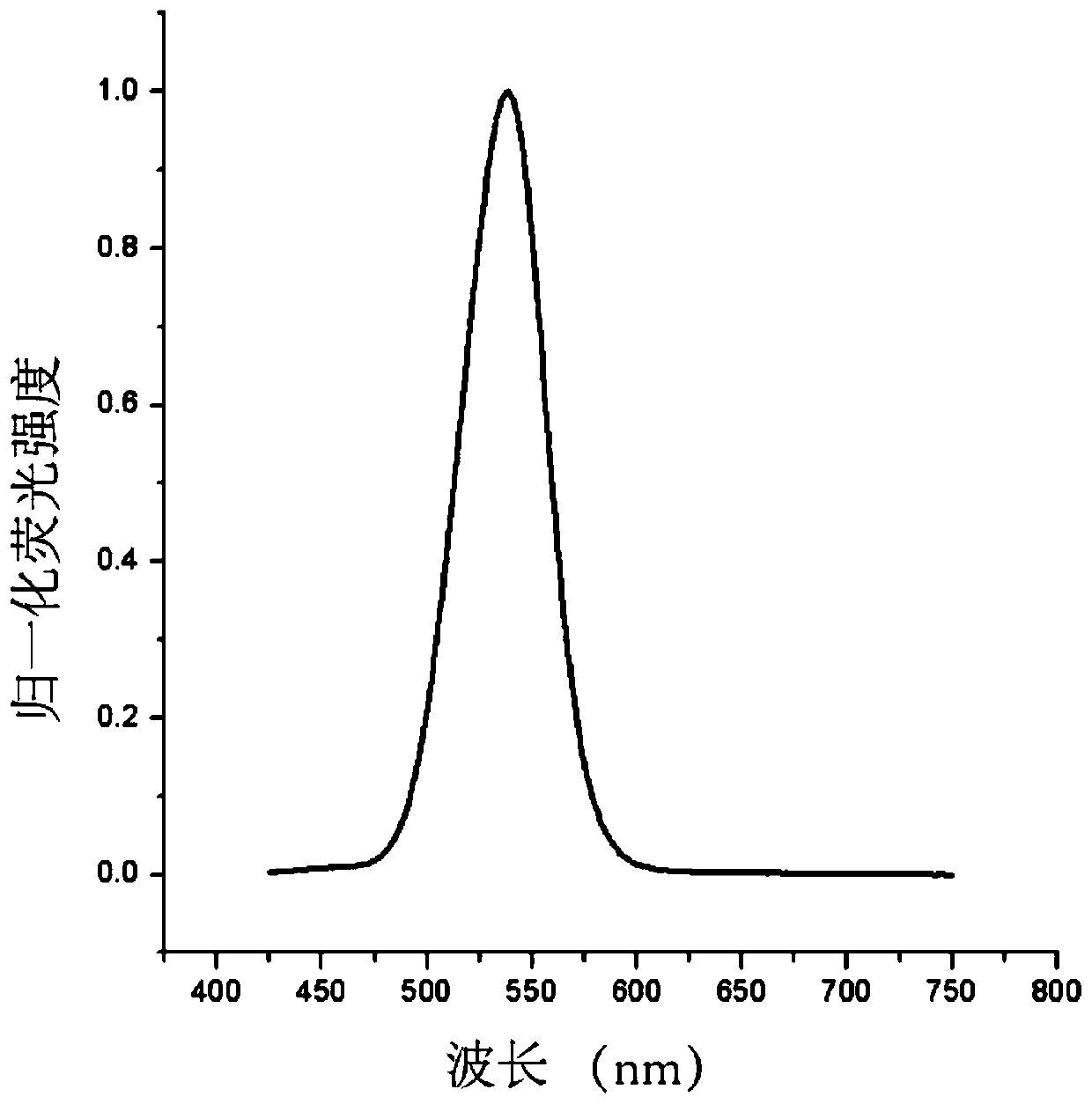

[0045]Mix 100 μl of water-soluble 520nm CdSe / ZnS quantum dots with 1 ml of polyethylene glycol diacrylate, add 20 mg of photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methyl Propiophenone is completely dissolved, shake and stir evenly to form a stable suspension as the water phase; take 20 ml of hexadecane, add 1 ml of emulsifier cetyl polyethylene glycol, mix and shake evenly to form an oil phase; put the oil phase into Put a magnet in a small beaker, stir magnetically at 600 rpm, drop the water phase into the stirring oil phase with a straw, after the addition is complete, keep stirring for 1 minute until evenly suspended, then turn on the UV lamp (wavelength 355-375nm, energy 200mW) placed above a small beaker, continue to irradiate, and the curing time lasts for 10 minutes; take out the cured suspension and centrifuge it with a mixed washing solution of cyclohexane and ethanol (V / V, 1:1) Wash several times, suspend the remaining solid in ethanol, use a stainless steel mic...

Embodiment 2

[0048] Mix 10 mg of zinc oxide nanoparticles with 1 ml of polyethylene glycol diacrylate, add 20 mg of photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone to dissolve completely, And shake and stir evenly to form a stable suspension as the water phase; take 20 ml of hexadecane, add 1 ml of emulsifier cetyl polyethylene glycol, mix and shake evenly to form an oil phase; put the oil phase into a small beaker, put Put in the magnet, carry out magnetic stirring at 700 rpm, drop the water phase into the stirring oil phase with a straw, keep stirring for 2 minutes until it is uniformly suspended, and then turn on the ultraviolet lamp (wavelength: 355-375nm, energy: 250mW) in the Above the small beaker, continue to irradiate, and the curing time lasts for 20 minutes; take out the solidified suspension, use cyclohexane and ethanol mixed washing solution (V / V, 1:1) to wash several times by centrifugation, and suspend the remaining solid in ethanol , using a stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com