Collagen/chondroitin sulfate composite artificial cornea and preparation method thereof

A technology of chondroitin sulfate and composite membrane, which is applied in medical science, prosthesis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

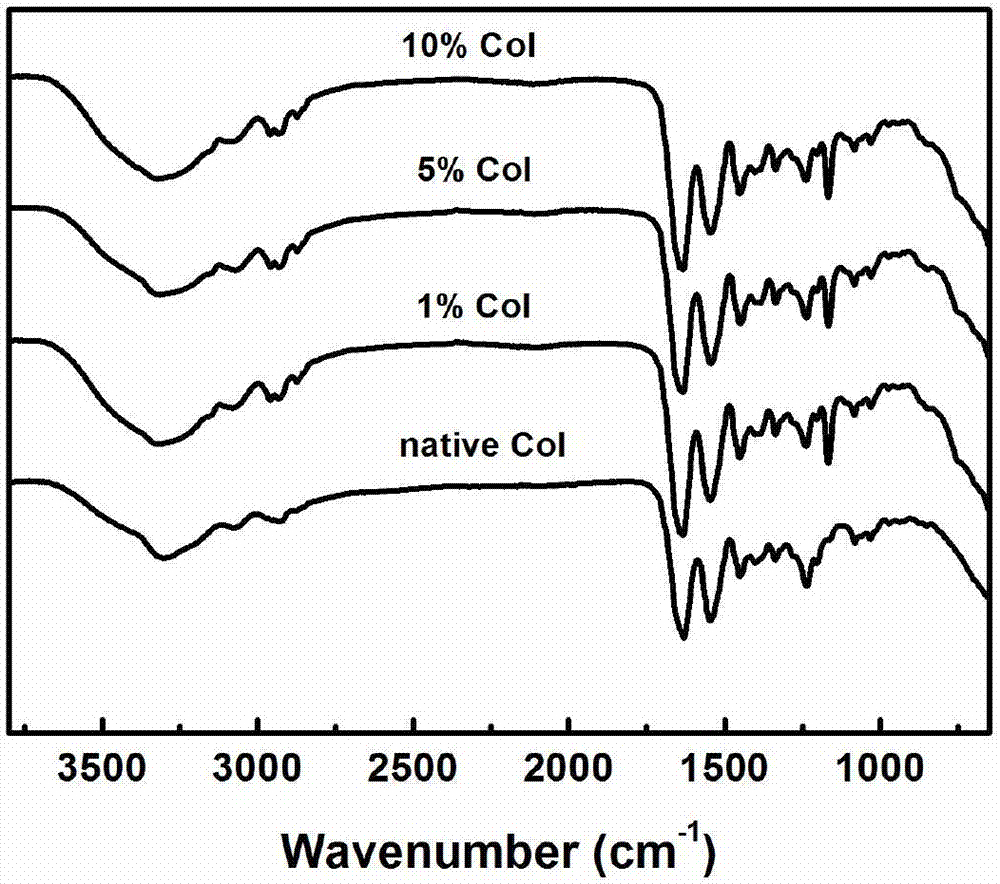

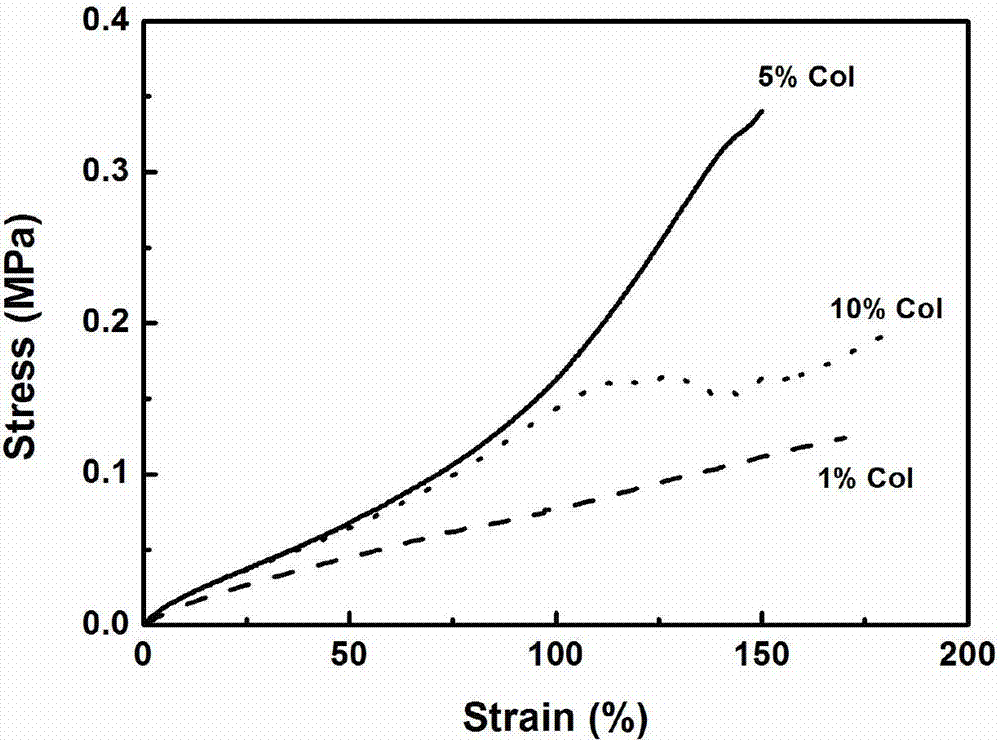

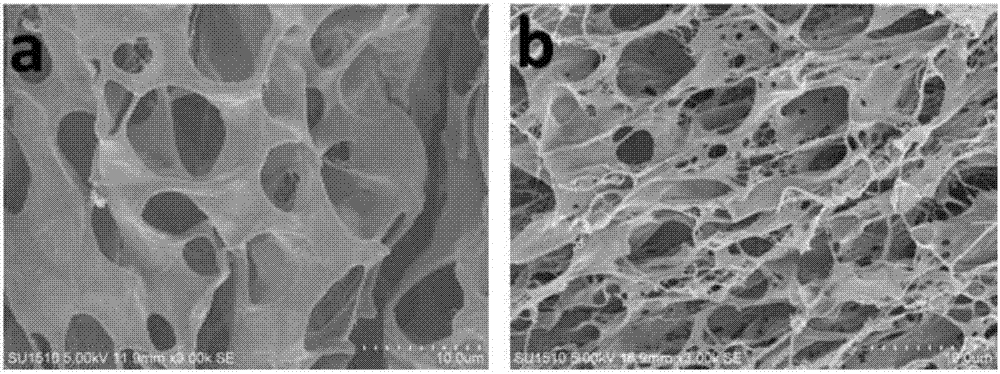

[0025] Weigh 10 mg of collagen freeze-dried raw materials, dissolve them in 10 mg of ionic liquid, stir and dissolve at 55°C for 2-4 hours, centrifuge the completely dissolved collagen solution at 4000 rpm for 10 min to de-bubble, and pour it into a mold by casting to spread it into a film . The mold is immersed in a 65-95% ethanol coagulation bath for 2-5 hours for regeneration and molding, and then immersed and washed with an 80% ethanol aqueous solution for 3 times to remove the ionic liquid in the gel film to obtain a gel sheet with a thickness of 0.2 mm. Dehydrate in a constant temperature oven at ℃ to form a dry collagen film Col-1.

Embodiment 2

[0027] Weigh 100 mg of collagen freeze-dried raw materials, dissolve them in 100 mg of ionic liquid, stir and dissolve at 55°C for 2 days, centrifuge the completely dissolved collagen solution at 4000 rpm for 10 min to de-bubble, and pour it into a mold using a casting method to spread it into a film. Immerse the mold in a 65-95% ethanol coagulation bath for 2-5 hours to regenerate the molding. Use an 80% ethanol aqueous solution to soak and wash three times to remove the ionic liquid from the gel film to obtain a gel sheet with a thickness of 02mm. Dehydrate in the incubator to form a dry collagen film Col-2.

Embodiment 3

[0029] Weigh 300 mg of collagen freeze-dried raw material, dissolve it in 300 mg of ionic liquid, stir and dissolve at 55°C for 3 days, centrifuge the completely dissolved collagen solution at 4000 rpm for 10 min to de-bubble, and pour it into a mold by casting to spread it into a film. The mold is immersed in a 65-95% ethanol coagulation bath for 2-5 hours for regeneration and molding, and then immersed and washed with an 80% ethanol aqueous solution for 3 times to remove the ionic liquid in the gel film to obtain a gel sheet with a thickness of 0.2 mm. Dehydrate in a constant temperature oven at ℃ to form a dry collagen film Col-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com