Rare earth hydride-carbon nano composite material and preparation method and application thereof

A rare earth hydride, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable production and commercial application, complex preparation method, low yield, etc., Achieve the effect of low cost, easy to scale up production and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] YH 3 - Graphite weight ratio of 1:2 nanocomposite

[0031] (1) Take 2g of metal Y block, polish it to remove the oxide layer on the surface, put it in a tube furnace, and react with hydrogen absorption for 3 hours at 350°C and 3MPa hydrogen pressure to obtain YH 3 powder.

[0032] (2) Take 200mg YH 3 Powder, mixed with 400 mg of 300-mesh graphite powder (purchased from Sinopharm Group), added 30 g of zirconia balls, filled the ball mill with 0.4 MPa of hydrogen, and milled for 150 min with a planetary ball mill at a speed of 200 rpm.

[0033] (3) Use a vacuum pump to evacuate the ball mill jar to a vacuum, put it in a glove box filled with argon and open it, take out the obtained mixed material with a spoon, and store it in the glove box.

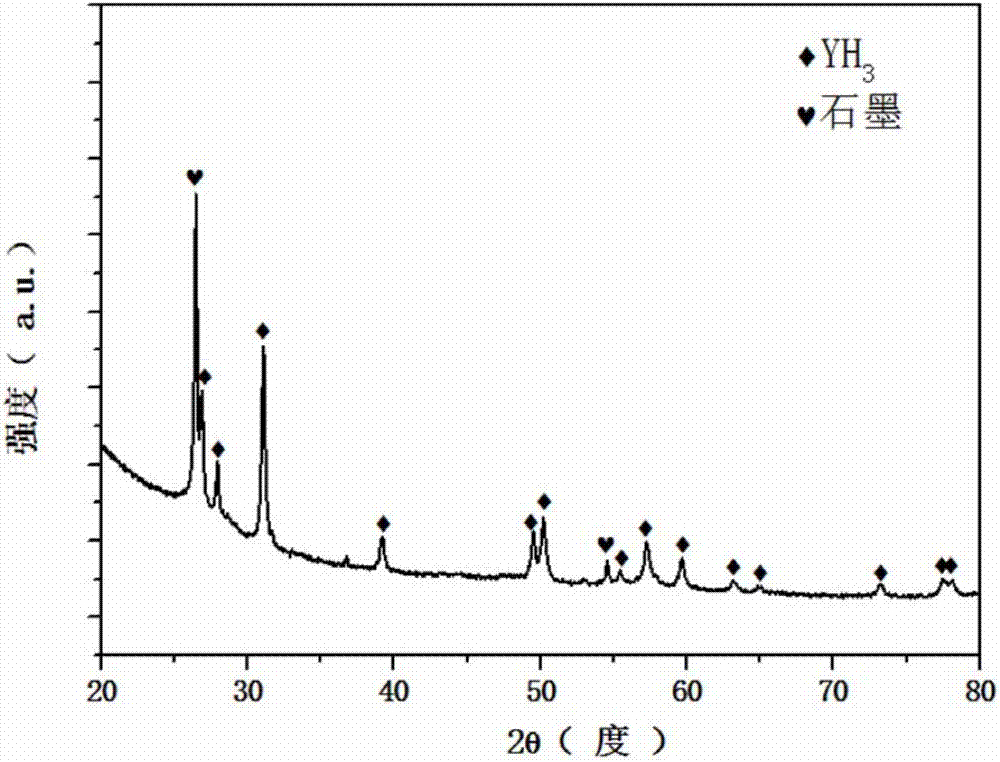

[0034] YH obtained after the above three steps 3 - X-ray diffraction and transmission electron microscopy of graphite nanocomposites such as figure 1 with figure 2 As can be seen from the figure, YH 3 And the crystallinity of...

Embodiment 2

[0036] YH 3 - Expanded graphite weight ratio of 1:0.2 nanocomposite

[0037] (1) Take 2g metal Y block, polish it to remove the oxide layer on the surface, put it in a tube furnace, and react with hydrogen absorption for 4 hours at 350°C and 4MPa hydrogen pressure to obtain YH 3 powder.

[0038] (2) Take 500mg YH 3 Powder, mixed with 100 mg of 200-mesh expanded graphite powder (purchased from Sinopharm), added 30 g of zirconia balls, filled the ball mill with 0.4 MPa of hydrogen, and milled for 60 min with a planetary ball mill at a speed of 200 rpm.

[0039] (3) Use a vacuum pump to evacuate the ball mill jar to a vacuum, put it in a glove box filled with argon and open it, take out the obtained mixed material with a spoon, and store it in the glove box.

[0040] YH obtained after the above three steps 3 - YH in expanded graphite nanocomposites 3 The crystallinity is good, the particle size is about 200nm, and it is evenly mixed with expanded graphite.

Embodiment 3

[0042] L 3 - Graphite weight ratio 1:1 nanocomposite

[0043] (1) Take 2g of metal La block, polish off the oxide layer on the surface, put it in a tube furnace, and react with hydrogen absorption for 3 hours at 350°C and 3.5MPa hydrogen pressure to obtain LaH 3 powder.

[0044] (2) Take 200mg LaH 3 Powder, mixed with 200 mg of 300-mesh graphite powder (purchased from Sinopharm), added 18 g of zirconia balls, filled the ball mill with 0.4 MPa of hydrogen, and milled for 300 min with a planetary ball mill at a speed of 250 rpm.

[0045] (3) Use a vacuum pump to evacuate the ball mill jar to a vacuum, put it in a glove box filled with argon and open it, take out the obtained mixed material with a spoon, and store it in the glove box.

[0046] LaH obtained after the above three steps 3 -LaH in graphite nanocomposites 3 Good crystallinity, particle size about 500nm, mixed with graphite evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com