Assembly type composite panel and heat insulation boards thereof

A technology of thermal insulation board and composite board, applied in thermal insulation, building components, construction and other directions, can solve the problems of easy detachment of insulation board joints, large difference in expansion coefficient, deformation of nails, etc., to avoid deformation, convenient installation process, Avoid the effect of dislocation deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

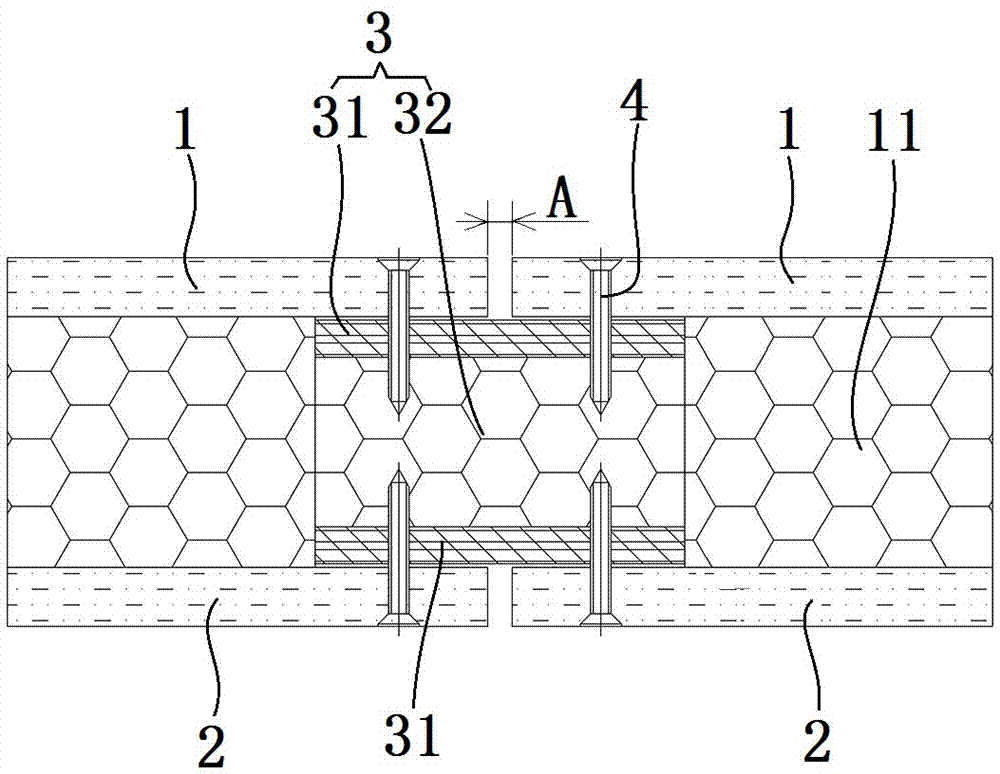

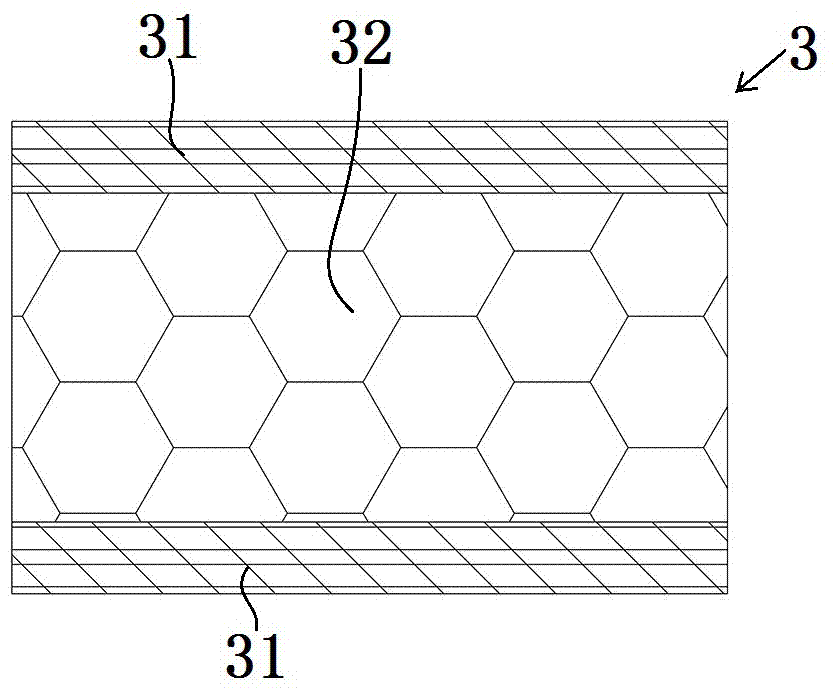

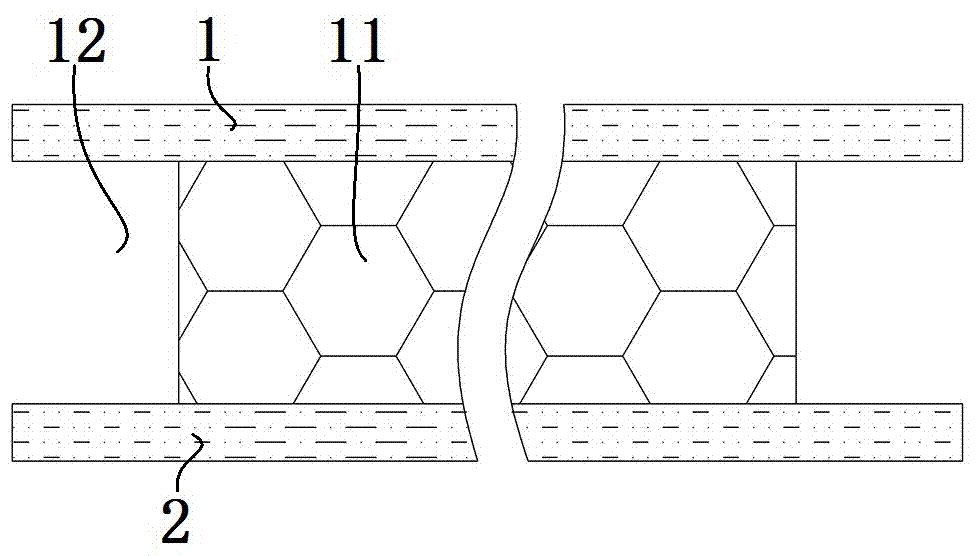

[0020] The specific embodiment of the prefabricated combination board of the present invention, as Figure 1 to Figure 3 As shown, the prefabricated composite panel includes at least two insulation boards connected in sequence, each insulation board includes a panel, the panel is divided into an inner panel 2 and an outer panel 1, both panels are made of oriented strand board, of course, in other embodiments , the two panels are also made of glass magnesium board, fiber reinforced calcium silicate board and other hard materials, there is an insulation board filling layer 11 between the two panels, the insulation board filling layer 11 is a foam filling layer, and the foam filling layer is made of It is made of modified PIR polyurethane foam with good energy-saving and flame-retardant effects. Of course, in other embodiments, other fire-proof and heat-ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com