Natural polymer for filtrate loss reducer for drilling fluid and preparation method thereof

A technology of natural polymer and fluid loss control agent, which is applied in the field of fluid loss control agent for drilling fluid and petroleum drilling aids, which can solve problems such as unspecified guidance plan, land environmental pollution, strong alkalinity, etc., and achieve reduction in drilling Complicated accidents, reduced fluid loss, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

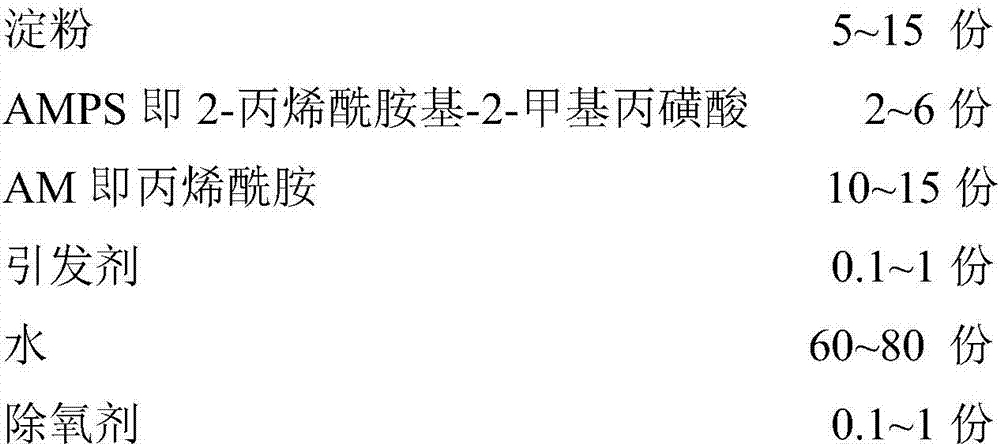

[0033] Embodiment 1: the fluid loss reducer natural high molecular polymer for drilling fluid of the present invention is to be made from the raw material of following weight ratio (weight part, mass part):

[0034]

[0035] The oxygen scavenger is sodium sulfite, and the initiator is sodium persulfate.

[0036] The preparation method of described fluid loss reducer natural polymer for drilling fluid comprises the following processing steps: 1. starch hydrolysis: in reactor, 10 parts of starch (corn starch) are dissolved in 72 parts of water, and the dissolution temperature is controlled Prepare starch solution at 35°C; ②Acidification of starch solution: Dissolve 5 parts of AMPS and 13 parts of AM in the starch solution prepared in step ①, control the dissolution temperature at 35°C, and adjust the pH of the solution to 4 with NaOH , to obtain starch acid solution; ③ deoxygenation of starch acid solution: raise the temperature of the starch acid solution to 62 ° C, add 0.5 ...

Embodiment 2

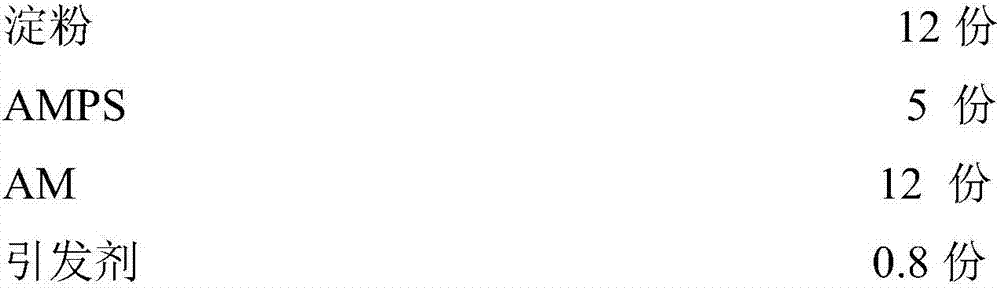

[0037] Embodiment 2: the fluid loss reducer for drilling fluid of the present invention is made from the raw materials of the following weight ratio (parts by weight, parts by mass):

[0038]

[0039] The oxygen scavenger is magnesium oxide, and the initiator is sodium persulfate.

[0040] The preparation method of described fluid loss reducer natural polymer for drilling fluid comprises the following process steps: 1. starch hydrolysis: in reactor, 12 parts of starch (potato starch) are dissolved in 76 parts of water, and the dissolution temperature is controlled Prepare starch solution at 45°C; ②Acidification of starch solution: Dissolve 5 parts of AMPS and 12 parts of AM in the starch solution prepared in step ①, control the dissolution temperature at 46°C, and adjust the pH of the solution to 5 with NaOH , to obtain the starch acid solution; ③ deoxygenation of the starch acid solution: the temperature of the starch acid solution was raised to 68 ° C, and 0.9 parts of ox...

Embodiment 3

[0041] Embodiment 3: the fluid loss control agent for drilling fluid of the present invention The natural polymer is made of the raw materials of the following weight ratio (parts by weight, parts by mass):

[0042]

[0043] The oxygen scavenger is sodium sulfite, and the initiator is potassium persulfate.

[0044] The preparation method of described fluid loss reducer natural polymer for drilling fluid comprises the following process steps: 1. Starch hydrolysis: dissolve 10 parts of starch (wheat starch) in 70 parts of water in a reactor, and the dissolution temperature is controlled Prepare starch solution at 50°C; ②Acidification of starch solution: Dissolve 6 parts of AMPS and 14 parts of AM in the starch solution prepared in step ①, control the dissolution temperature at 48°C, and adjust the pH of the solution to 6 with NaOH , to obtain starch acid solution; ③ deoxygenation of starch acid solution: raise the temperature of the starch acid solution to 70 ° C, add 0.7 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com