Degradable skull lock capable of improving skull healing ability

A skull and ability technology, applied in the field of degradable skull lock, can solve the problems of slow healing, infection, and non-degradable skull, and achieve the effect of promoting healing, preventing infection, and inhibiting bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

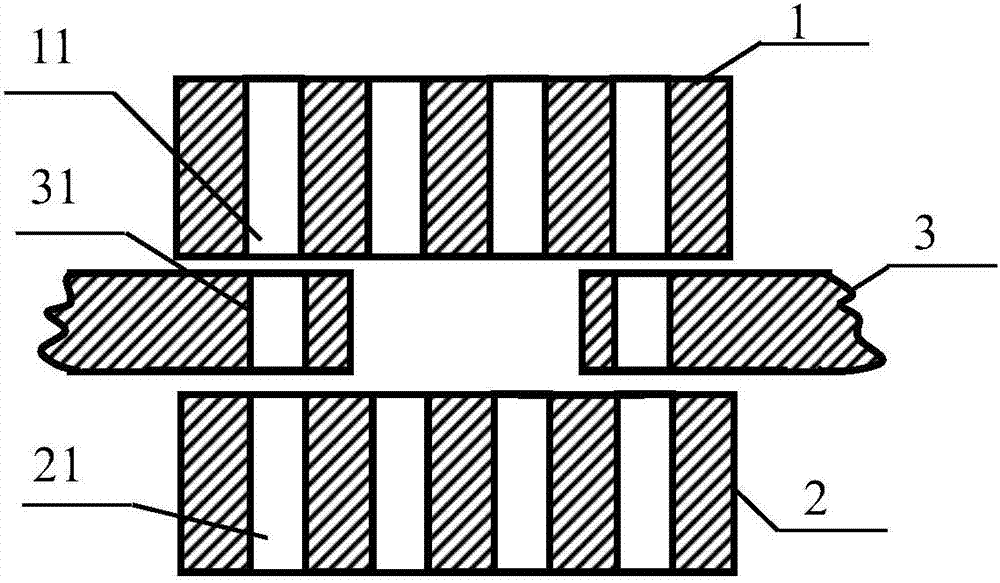

[0049] The skull lock of this embodiment adopts structure one, wherein the middle layer of upper and lower lock plate materials is taken from rolled pure magnesium (purity is 99.99%) plate. A Φ5mm×0.8mm locking piece with a toothed edge is prepared by stamping, and 4 first through holes and 4 second through holes with a diameter of Φ0.5mm are drilled. The upper and lower ceramic layers of the locking piece are made of original It is obtained by a high-temperature ceramic method, and the thickness of the obtained ceramic layer is 20 μm. The connecting wire is made of pure magnesium (99.99% pure) wire with a diameter of 0.4 mm to connect the upper and lower locking pieces. The functional wire is made of pure magnesium (purity: 99.99%), the cross section is circular, the diameter is 1mm, and the diameter of the third through hole is 0.5mm. The beams are arranged continuously, with a thickness of 0.2 mm and a width of 0.5 mm. The surface of connecting wire, functional wire and b...

Embodiment 2

[0052] The skull lock of the present embodiment adopts the second structure, wherein the middle layer of the upper and lower lock plate materials is taken from rolled state ZK60 magnesium alloy (purity is 99.9%) plate. A Φ8mm×1mm locking piece with a 0.5mm diameter limiter and a toothed edge is prepared by punching, and 4 first through holes and 4 second through holes with a diameter of Φ0.5mm are drilled, and the locking piece is The upper and lower ceramic layers are formed by an in-situ high-temperature ceramic method, and the thickness of the obtained ceramic layer is 50 μm. The connecting wire is made of polylactic acid wire with a diameter of 0.4mm, which connects the upper and lower locking pieces. The functional wire is made of ZK60 magnesium alloy (purity: 99.9%), the cross section is circular, the diameter is 1.5mm, and the diameter of the third through hole is 0.5mm. The beams are arranged continuously, with a thickness of 0.3 mm and a width of 0.6 mm. The surface...

Embodiment 3

[0055] The skull lock of the present embodiment adopts the third structure, wherein the middle layer of the upper and lower lock plate materials is taken from a rolled magnesium-strontium alloy (purity is 99.9%) plate. The Φ12mm×1.5mm locking piece with toothed edge is made by stamping method, the height of the middle protrusion of the lower locking piece is 2mm, and the width is 2mm. The upper and lower locking pieces are drilled with 4 first through holes with a diameter of Φ0.7mm and 4 second vias. The upper and lower ceramic layers of the locking piece are obtained by electrodeposition, and the thickness of the obtained ceramic layer is about 50 μm. The connecting wire adopts magnesium-strontium alloy (purity is 99.9%) wire material with a diameter of 0.6mm, and connects the upper and lower locking pieces. The surface of connecting wire and functional wire is prepared with calcium phosphorus coating by electrodeposition method.

[0056] The skull lock in this example was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com