Grouting conductive silver paste applied to low-temperature co-fired ceramic and preparation method thereof

A technology of low-temperature co-fired ceramics and conductive silver paste, which is used in cable/conductor manufacturing, circuits, electrical components, etc. Excellent electrical conductivity and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

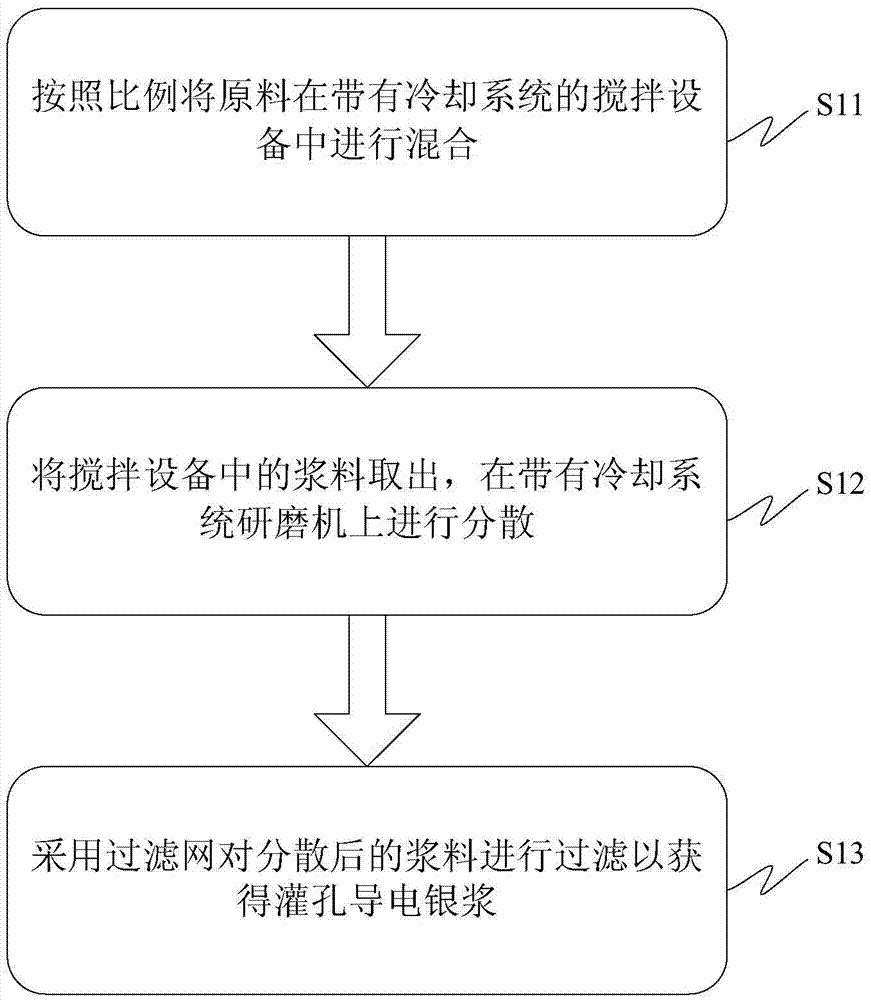

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a conductive silver paste for filling holes applied to low-temperature co-fired ceramics. The conductive silver paste for filling holes includes the following components in terms of mass ratio: 80% silver particles, 10% inorganic additives, 5% % carrier, 0.5% adjuvant, and 4.5% solvent.

[0030] As an example, the silver particles are selected from silver powders whose morphology is spherical and whose particle size is selected from silver powders whose D50 is between 1-3 microns and D90 is not greater than 5 microns.

[0031] As an example, the inorganic additives include the following components in parts by weight: 25 parts of Al 2 o 3 , 30 parts of SiO 2 , 10 copies of Bi 2 o 3 , 25 parts of CaCO 3 , and 10 parts of SrCaO 3 .

[0032] As an example, the carrier includes a mixture of the following components in mass ratio: 30% specialty resin, and 70% solvent. Further, the special resin is selected from esters, and the solvent is selec...

Embodiment 2

[0041] This embodiment provides a conductive silver paste for filling holes applied to low-temperature co-fired ceramics. The conductive silver paste for filling holes includes the following components in terms of mass ratio: 95% silver particles, 1% inorganic additives, 1 % carrier, 0.3% adjuvant, and 2.7% solvent.

[0042] As an example, the silver particles are selected from silver powders whose morphology is flake, and whose particle size is selected from silver powders whose D50 is between 1-3 microns and D90 is not greater than 5 microns.

[0043]As an example, the inorganic additives include the following components in parts by weight: 20 parts of Al 2 o 3 , 35 parts of SiO 2 , 10 copies of Bi 2 o 3 , 20 parts of CaCO 3 , and 15 parts of SrCaO 3 .

[0044] As an example, the carrier includes a mixture of the following components in mass ratio: 10% specialty resin, and 90% solvent. Further, the special resin is selected from alcohol esters, and the solvent is sel...

Embodiment 3

[0052] This embodiment provides a conductive silver paste for filling holes applied to low-temperature co-fired ceramics. The conductive silver paste for filling holes includes the following components in terms of mass ratio: 85% silver particles, 5% inorganic additives, 6 % carrier, 1% adjuvant, and 3% solvent.

[0053] As an example, the size of the silver particles is selected from silver powders whose D50 is between 1 and 3 microns and whose D90 is not greater than 5 microns, and the shape is 50 parts flake and 50 parts spherical.

[0054] As an example, the inorganic additives include the following components in parts by weight: 40 parts of Al 2 o 3 , 15 parts of SiO 2 , 35 copies of Bi 2 o 3 , 5 parts of CaCO 3 , and 5 parts of SrCaO 3 .

[0055] As an example, the carrier includes a mixture of the following components in mass ratio: 20% specialty resin, and 80% solvent. Further, the special resin is cellulose, and the solvent is alcohol.

[0056] As an example,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com