Multi-grain-size uniform spherical powder batch preparation device and method based on uniform metal droplet spraying

A technology of metal droplets and spherical powders, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problems of low productivity and achieve the effects of small vibration, uniform size, and consistent thermal history

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

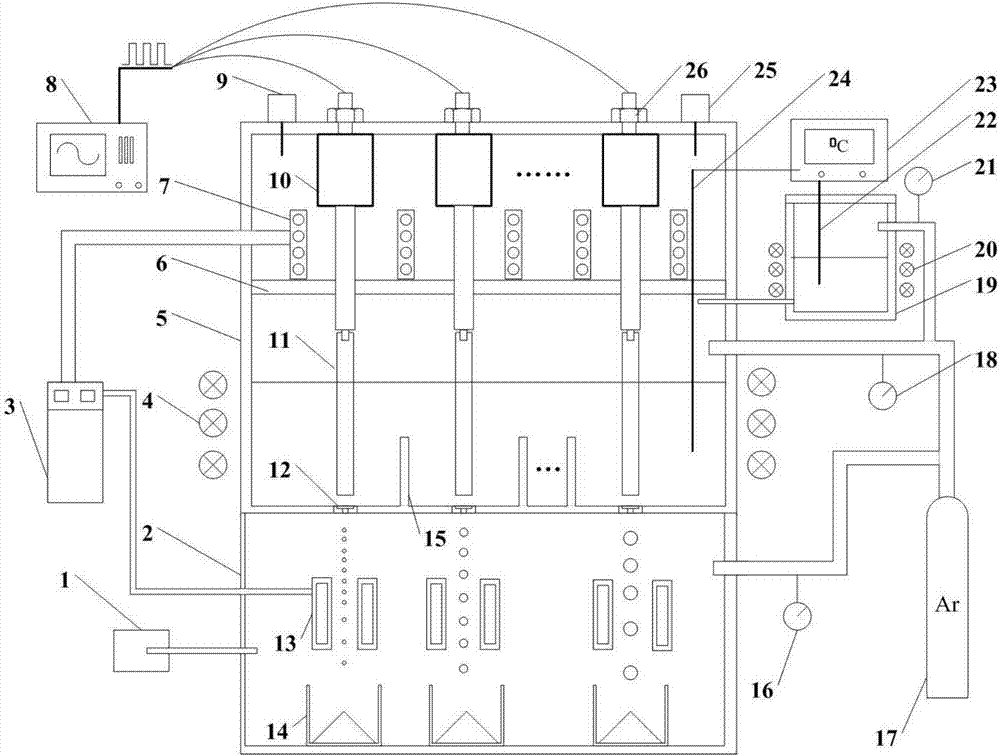

[0023] The following examples refer to figure 1 .

[0024] Device example:

[0025] The present invention is based on the uniform metal droplet spraying multi-particle size uniform spherical powder batch preparation device comprising a vacuum pump 1, a collection box 2, a cooling cabinet 3, an induction heating coil 4, a chamber 5, a heat shield 6, a cooling ring 7, a signal Generator 8, oxygen content detector 9, piezoelectric ceramics 10, vibrating rod 11, nozzle 12, cooler 13, powder collector 14, barrier plate 15, collection box barometer 16, argon cylinder 17, chamber pressure Table 18, crucible 19, induction heater 20, crucible pressure gauge 21, crucible thermocouple 22, temperature controller 23, chamber thermocouple 24, water content analyzer 25 and fasteners 26. The separation of the chamber 5 and the crucible 19 can continuously add metal raw materials in the crucible 19, so that the uninterrupted production of metal powder can be realized. Wherein, argon gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com