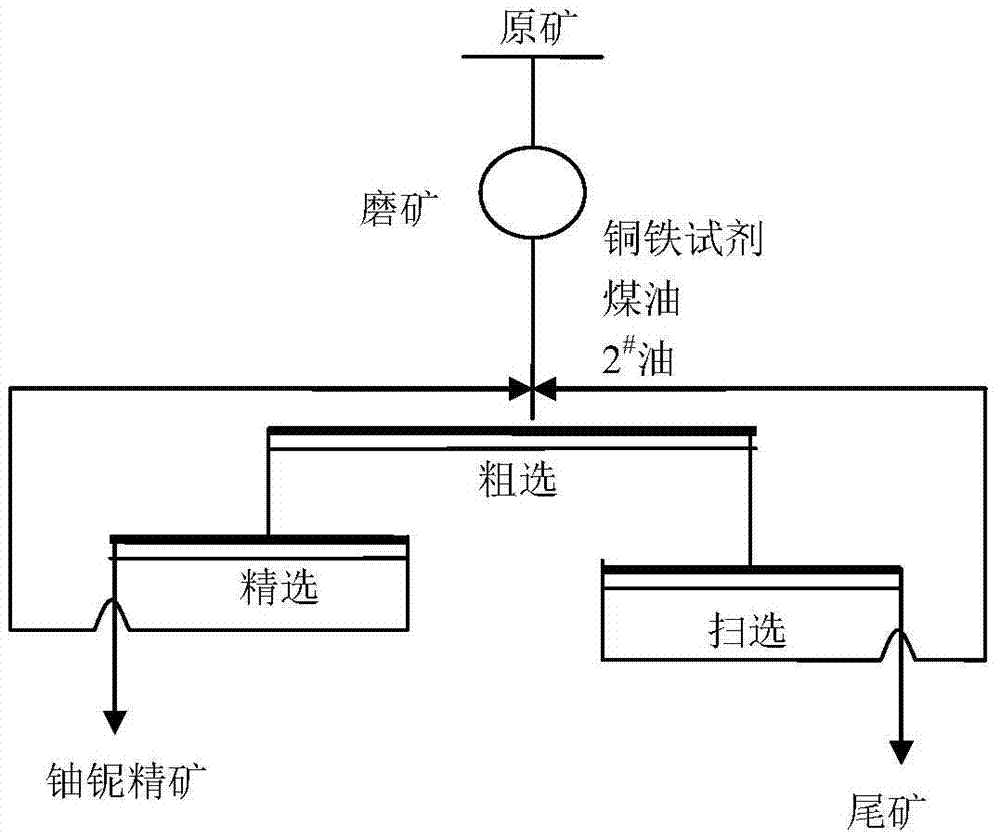

Niobium titanium uranium ore flotation process

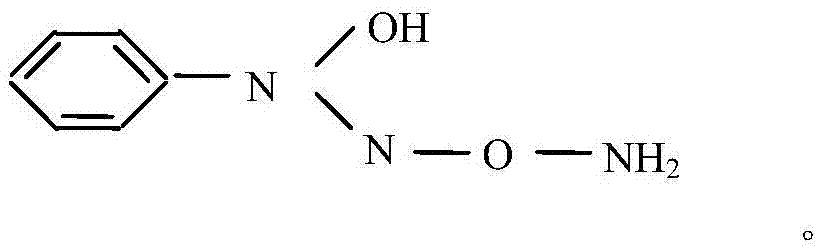

A niobium-titanium-uranium ore and flotation technology, which is applied in flotation, solid separation, etc., can solve the problems of high uranium extraction cost and low grade of uranium concentrate, and achieve the effects of good selectivity, excellent indicators and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Adopt collector copper-iron reagent of the present invention, carry out laboratory flotation experiment research to certain niobium-titanium-uranium ore, its main uranium mineral is niobium-titanium-uranium ore, and gangue mineral mainly contains microplagioclase, quartz, Neonite, albite, iron-rich sodium amphibole, biotite, calcite, etc. The grade of uranium in the flotation raw ore is 0.077%. In the flotation process, add collector 2000g / t of the present invention, stir 5min, auxiliary collector kerosene 200g / t, stir 5min, foaming agent 2 # Oil 50g / t, stirring for 5min. Inflatable bubbling flotation for 5 to 8 minutes. The uranium concentrate with a yield of 9.23%, a uranium content of 0.766%, and a recovery rate of 91.75% can be obtained through a closed-circuit process of one roughing, one beneficiation and one sweeping. The flotation results show that the niobium-titanium ore is better enriched by using the flotation agent of the present invention, and the recov...

Embodiment 2

[0039] After preliminary enrichment of a certain niobium-titanium-uranium ore, the uranium grade can reach 0.065% after gravity separation, and the uranium grade can reach 0.078% after flotation to remove sulfide ore and magnetic separation to remove magnetite. When the grinding fineness -0.074mm accounts for 60%, adopt collector copper-iron reagent of the present invention to flotation niobium-titanium-uranium ore, change the consumption of copper-iron reagent to flotation raw ore, auxiliary collector kerosene dosage 200g / t , frother 2 # See Table 2 for the flotation index of uranium under the conditions of oil consumption of 40g / t, pulp temperature of 30°C, primary roughing, and different dosages of copper and iron collectors.

[0040] Table 2 The test results of different copper and iron reagent dosages

[0041]

[0042] It can be seen from Table 2 that when the uranium grade of the flotation raw ore is between 0.05% and 0.2%, a better flotation effect is obtained when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com