Charcoal amine sulfur dual-group modification method

A biochar and group technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as small pore volume, high ash content of biochar, and small specific surface area. Achieve strong passivation ability and improve physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

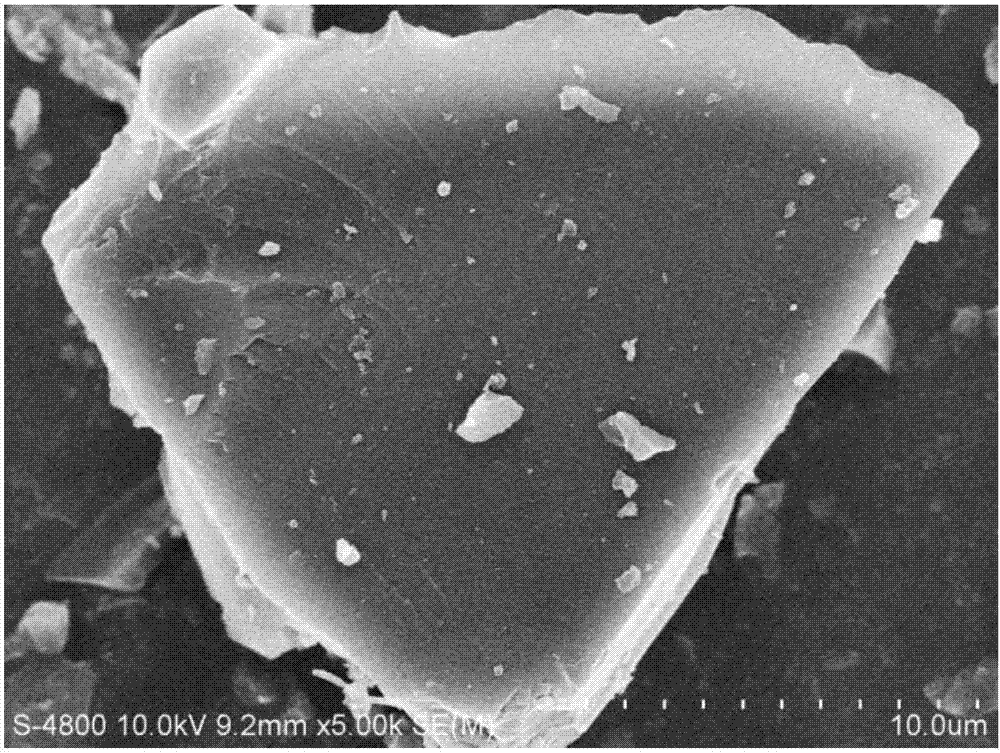

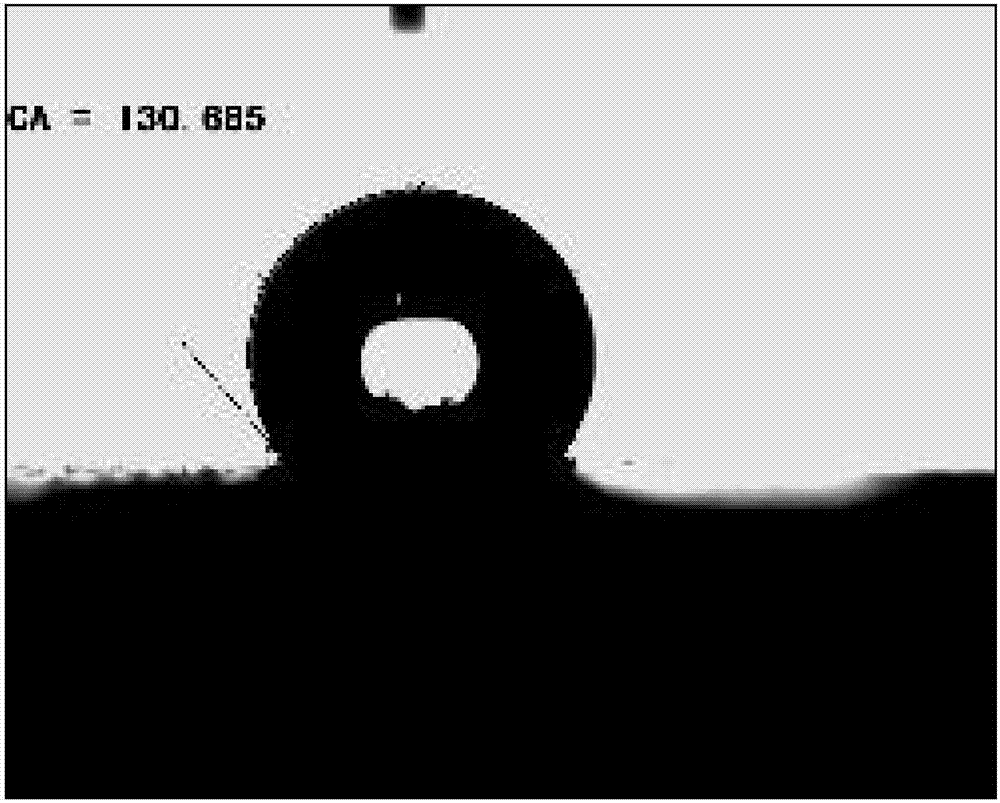

[0021] A kind of amine sulfur modification method of biochar, the step of specific modification is as follows:

[0022] (1) Acidify and oxidize biochar with nitric acid, and ultrasonically shake for 2 hours; centrifuge and wash to neutral to obtain acidified activated biochar BC-O; the concentration of nitric acid is controlled at 9mol / L;

[0023] (2) Adjust the pH of activated biochar BC-O to 11, add formaldehyde at a constant temperature of 60°C, react for 40 minutes, add diethylenetriamine dropwise and react for 6 hours, and obtain amino-modified biochar BC-N; The molar ratio of carbon BC-O: formaldehyde: diethylenetriamine is 1:0.9:1.1;

[0024] After cooling to room temperature, add NaOH with a mass fraction of 45%, and then dropwise add carbon disulfide to carry out sulfur group reaction. After the dropwise addition, raise the temperature to 60°C and react for 7 hours; centrifuge, wash, and dry to obtain amine-sulfur double-group modified biochar BC-SN, wherein the mola...

Embodiment 2

[0026] A kind of amine sulfur modification method of biochar, the step of specific modification is as follows:

[0027] (1) The biochar was acidified and oxidized with nitric acid, and ultrasonically oscillated for 3 hours; centrifuged and washed to neutral to obtain acidified activated biochar BC-O; the concentration of nitric acid was controlled at 8mol / L;

[0028] (2) Adjust the pH of BC-O to 10.5, add formaldehyde at a constant temperature of 40°C, react for 30 minutes, add triethylenetetramine dropwise and react for 4 hours to obtain amino-modified biochar BC-N; among them, activated biochar BC- The molar ratio of O: formaldehyde: triethylenetetramine is 1:0.8:1.2.

[0029] After cooling to room temperature, add NaOH with a mass fraction of 50%, and then dropwise add carbon disulfide to carry out sulfur group reaction. After the dropwise addition, raise the temperature to 80°C, and react for 5 hours; centrifuge, wash, and dry to obtain amine-sulfur double-group modified b...

Embodiment 3

[0032] A kind of amine sulfur modification method of biochar, the step of concrete modification is as follows:

[0033] (1) The biochar was acidified and oxidized with nitric acid, and ultrasonically oscillated for 5 hours; centrifuged and washed to neutral to obtain acidified activated biochar BC-O; the concentration of nitric acid was controlled at 10mol / L;

[0034] (2) Adjust the pH of activated biochar BC-O to 12, add formaldehyde at a constant temperature of 50°C, react for 20 minutes, add triethylenetetramine dropwise and react for 5 hours to obtain amino-modified biochar BC-N; The molar ratio of carbon BC-O: formaldehyde: triethylenetetramine is 1:0.8:1.1.

[0035] After cooling to room temperature, add NaOH with a mass fraction of 40%, and then dropwise add carbon disulfide to carry out sulfur group reaction. After the dropwise addition, raise the temperature to 70°C and react for 5 hours; centrifuge, wash, and dry to obtain amine-sulfur double-group modified biochar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com