Artificial nerve scaffold and preparation method and application thereof

A technology of artificial nerves and nerve guides, applied in medical science, prostheses, surgery, etc., can solve the problems of nerve diameter mismatch between donor and recipient, damaged function of donor area, difficulty in scale-up production, etc., to prevent connective Scar tissue grows in, promotes the speed of nerve regeneration, and is conducive to the effect of growing in and rebuilding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Dosing

[0038] Dissolve collagen and polylactic acid (PLA) in hexafluoroisopropanol (HFIP) at a mass ratio of 1:9, with a material-to-liquid ratio of 1:10, and stir until completely dissolved to obtain a uniform spinning solution for the outer layer of the nerve guide (O);

[0039] The collagen was dissolved in hexafluoroisopropanol (HFIP) with a material-to-liquid ratio of 1:10, and stirred until it was completely dissolved to obtain a uniform spinning solution (I) for the inner layer of the nerve guide.

[0040] Dissolve collagen in pure water so that the final concentration reaches 1 mg / ml to obtain the "natural polymer binder", and store it at 4°C after filtration and sterilization.

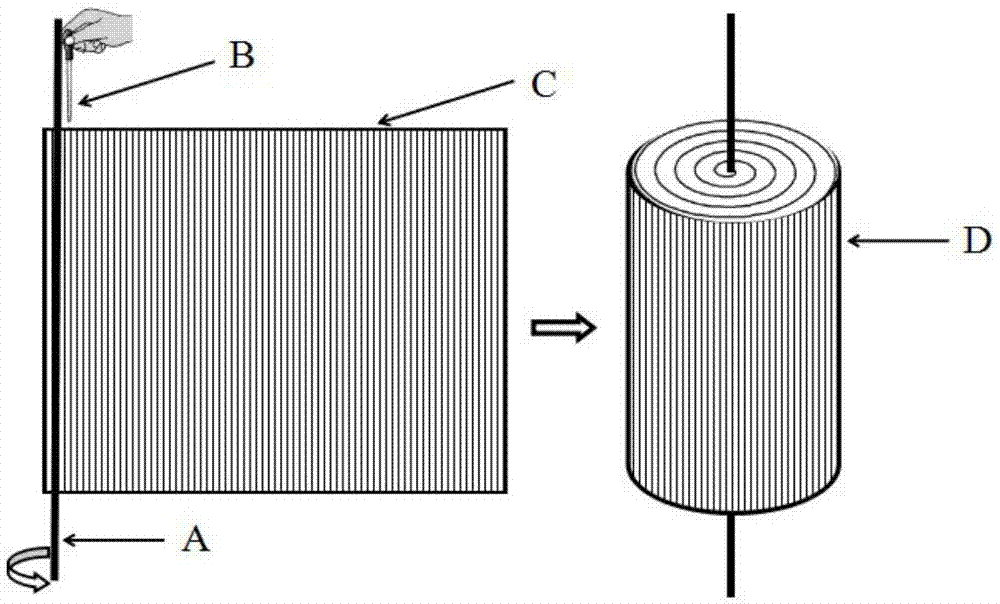

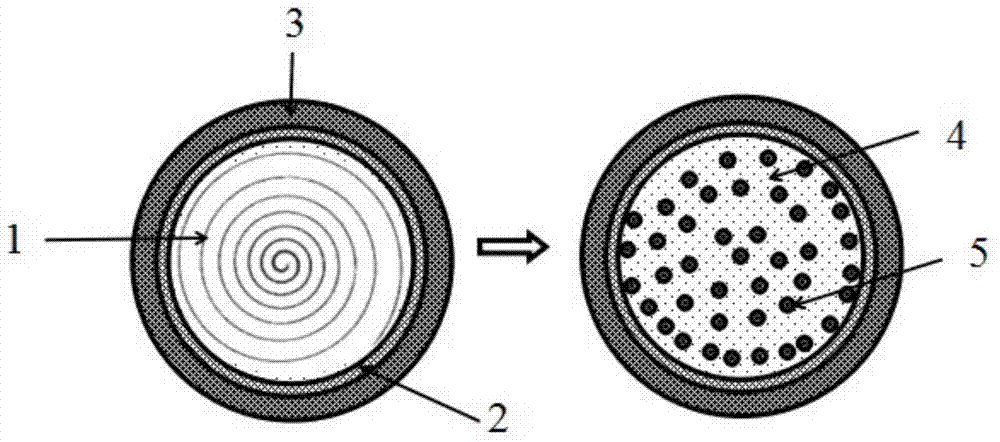

[0041] 2. Preparation of two-component nanofiber membrane

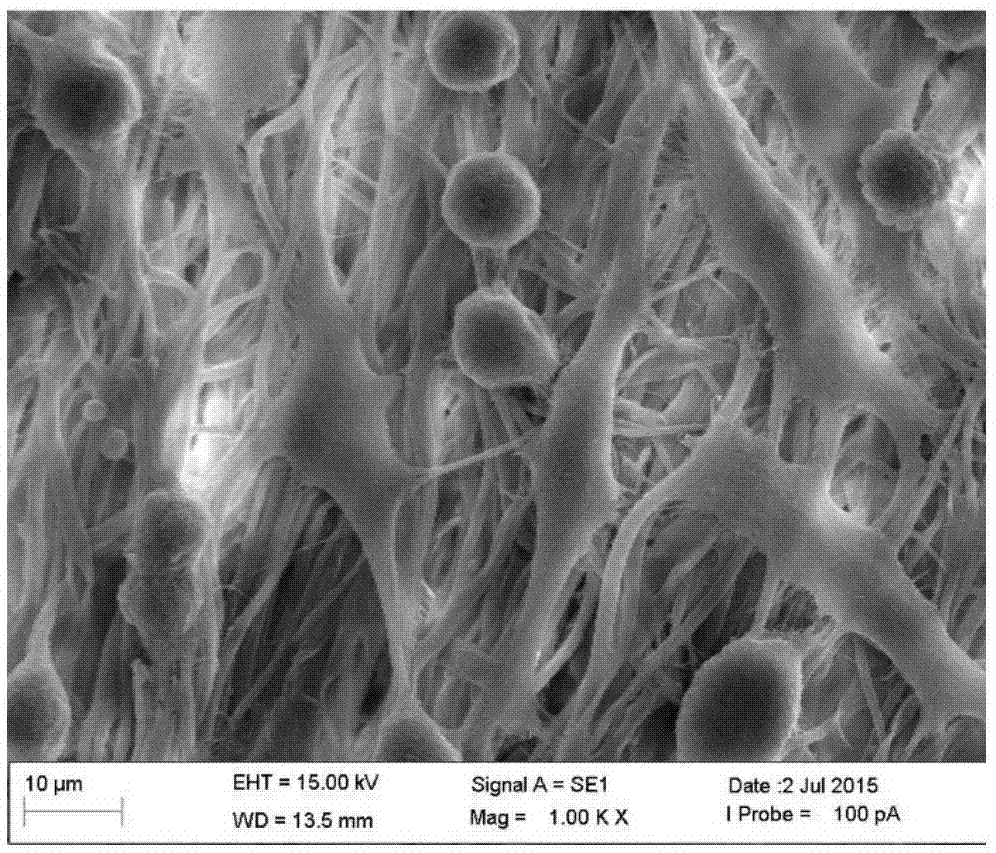

[0042] Nanofiber membranes with a certain orientation are obtained by electrospinning with a conjugate electrostatic spinning device, that is, the nozzles of the two spinning solutions are arranged on both sides above th...

Embodiment 2

[0051] 1. Dosing

[0052] Dissolve gelatin and polylactide caprolactone copolymer in trifluoroethanol according to the mass ratio of 2:8, the ratio of solid to liquid is 1:20, and stir until completely dissolved to obtain a uniform outer layer spinning solution of nerve guide (O) ;

[0053] Gelatin and polylactide caprolactone were dissolved in trifluoroethanol at a mass ratio of 50:1, and the material-to-liquid ratio was 1:20, and stirred until completely dissolved to obtain a uniform inner layer spinning solution (I) of the nerve conduit.

[0054] Dissolve gelatin in pure water so that the final concentration reaches 3mg / ml to obtain the "natural polymer binder", and store it at 4°C after filtration and sterilization.

[0055] 2. Preparation of two-component nanofiber membrane

[0056] Nanofiber membranes with a certain orientation are obtained by electrospinning with a conjugate electrostatic spinning device, that is, the nozzles of the two spinning solutions are arranged...

Embodiment 3

[0065] 1. Dosing

[0066]Dissolve chitosan and polylactide caprolactone copolymer in acetone / acetic acid mixed solvent (volume ratio 20:1) according to the ratio of mass ratio 4:6, and the ratio of solid to liquid is 1:8, and stir until completely dissolved to obtain a uniform The outer layer spinning solution (O) of the nerve guide;

[0067] Dissolve collagen and polyglycolic acid (PGA) in hexafluoroisopropanol (HFIP) at a mass ratio of 10:1, with a material-to-liquid ratio of 1:8, and stir until completely dissolved to obtain a uniform nerve guide inner layer spinning Liquid (I).

[0068] The nerve growth factor was dissolved in pure water to a final concentration of 50 μg / ml, and stirred until completely dissolved to obtain a uniform core layer solution (Y).

[0069] Dissolve sodium hyaluronate in pure water so that the final concentration reaches 10mg / ml to obtain the "natural polymer binder", and store it at 4°C after filtration and sterilization.

[0070] 2. Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com