A combined type electric heating tube formed by a heater having a nonmetal tube arranged outside a metal tube and a sinking injection molded connecting piece

A technology of non-metallic tubes and connecting parts, applied in the field of electric heating tubes, can solve the problems of reducing heating efficiency, scaling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

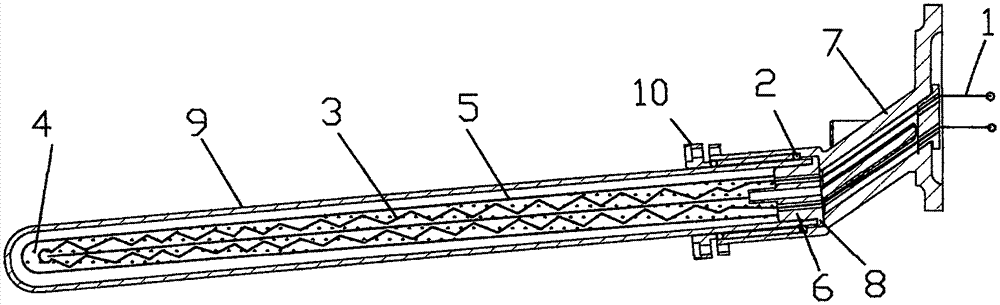

[0008] In the accompanying drawings, lead-out rod 1, sealing member 2, electric heating wire 3, magnesium oxide powder 4, heater 5 with electric heating wire in the straight metal pipe and insulated with magnesium oxide powder and metal pipe, non-metallic plug 6, sinking Type non-metallic material injection molded connector 7, a step 8 for absorbing axial force in the hole where the tubular heater is installed on the connector, straight non-metallic pipe or shell 9 with a blind hole, and a locking ring 10.

[0009] figure 1 It is a structural diagram of the combination of a heater with a non-metallic tube outside the metal tube and a connecting piece 7 made of plastic material injection molding. The function of the connecting piece is to connect with various water heating devices and make the electric heating tube in the water tank Sinking, a step 8 is formed in the inner hole to block the axial force of the tubular heater; the metal tubular heater 5 is equipped with a heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com