Horizontal type double-liner fast-heating water storage type electric water heater adopting combined electric heating tubes

A fast-heating water storage type and electric water heater technology, applied in electric heating devices, water heaters, fluid heaters, etc., can solve problems such as scale formation, lower heating efficiency, and corrosion breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

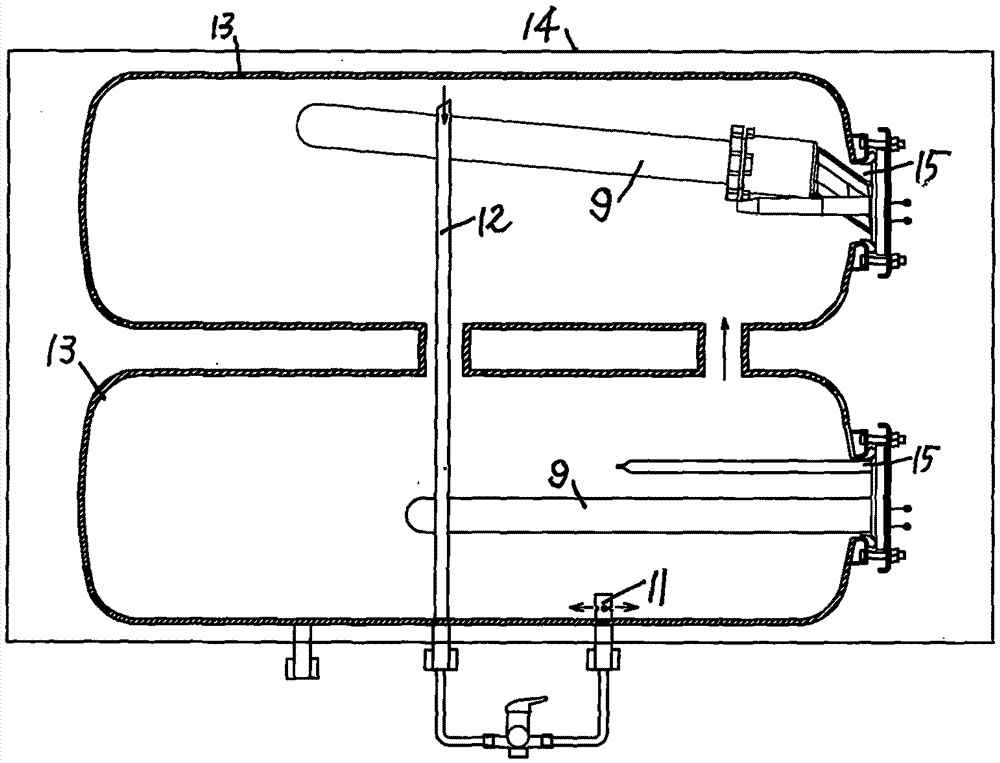

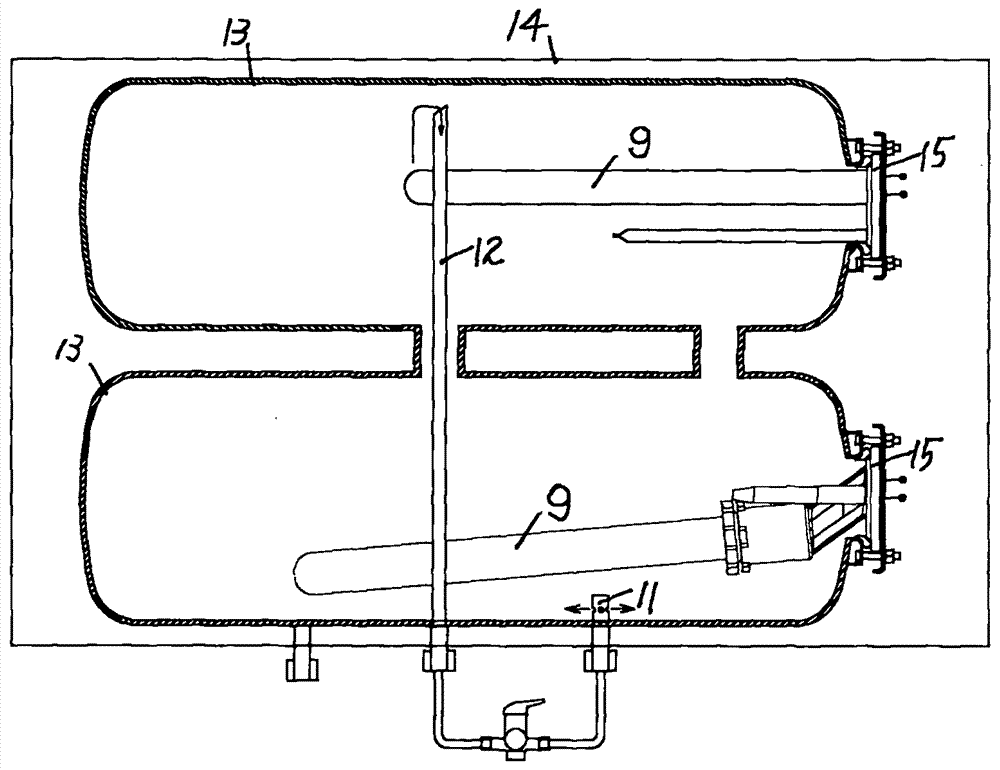

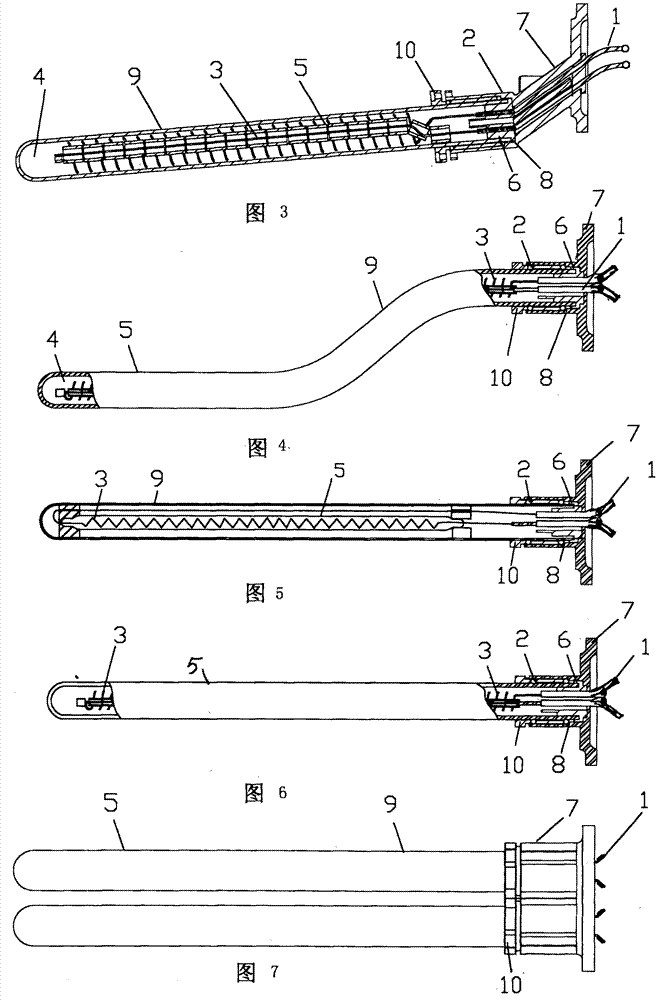

[0008] attached picture Among them, lead-out rod or terminal 1, seal 2, electric heating wire or electric heating tube 3 (including carbon fiber tube or halogen tube or dry-fired metal electric heating tube), magnesium oxide powder or air 4, non-metallic tubular heater 5, non-metallic Plug 6, metal or non-metal connecting piece 7, tubular heater installation hole 8, combined electric heating tube 9, locking ring or compression cover 10, cold water inlet 11, hot water outlet 12, water tank 13, shell 14 , Flange mouth 15.

[0009] figure 1 , figure 2 It is a horizontal double-tank (that is, 2 water tanks) fast-heating water storage electric water heater using a combined electric heating tube. picture The combined electric heating tube 9 is installed on the flange port 15 of each water tank 13; when the water is discharged, the upper electric heating tube is connected, the natural water temperature is > 20°C, and hot water > 40°C flows out immediately, which is called fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com