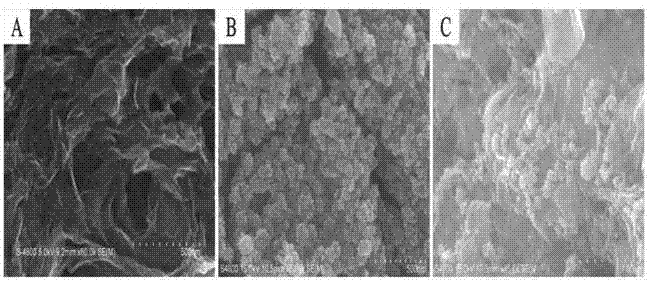

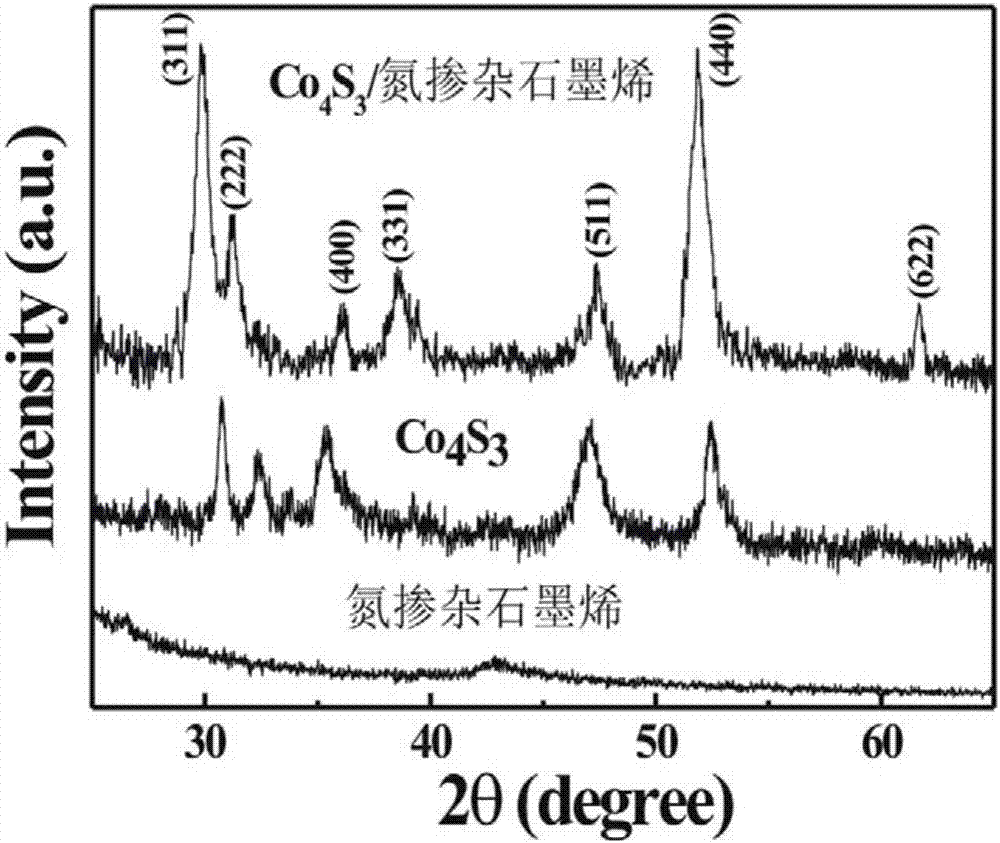

Preparation method of Co4S3 / nitrogen doped graphene composite material and application thereof

A technology of nitrogen-doped graphene and composite materials, which is applied in the fields of analyzing materials, electrochemical variables of materials, and material analysis by electromagnetic means, and can solve the problems of low sensitivity and selectivity of electrochemical sensing, narrow linear response range, raw materials, etc. Excessive consumption and other problems, to achieve the effect of wide detection linear range, easy separation and purification, and less raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 50 mg of graphene oxide powder in 50 mL of twice distilled water, and disperse it into a uniform solution by ultrasonication for 2 hours.

[0033] (2) Adjust the graphene dispersion to a pH of about 9 with ammoniacal liquor with a mass concentration of 30%, then add 0.8mL of hydrazine hydrate with a mass concentration of 85% and stir for 15 minutes, and heat the resulting mixed solution at 40°C Reflux for 36 hours.

[0034] (3) After the reaction, centrifuged and washed several times with secondary water and ethanol, and finally the centrifuged product was dried in a vacuum oven at 15° C. for 18 hours to obtain nitrogen-doped graphene powder.

[0035] (4) Take by weighing 15mg of nitrogen-doped graphene powder in a mixed solution of 70mL of secondary water and ethanol (1.0:1.0), ultrasonic for 30 minutes, after making it uniformly dispersed, add 525mg of cobalt acetate tetrahydrate and 140mg of thiourea, Continue to sonicate for 15 minutes and stir to dissolv...

Embodiment 2

[0037] (1) Weigh 50 mg of graphene oxide powder in 50 mL of twice distilled water, and disperse it into a uniform solution by ultrasonication for 3 hours.

[0038] (2) Adjust the graphene dispersion to a pH of about 10 with ammoniacal liquor with a mass concentration of 30%, then add 1.0 mL of hydrazine hydrate with a mass concentration of 85% and stir for 8 minutes, and place the resulting mixed solution at 50° C. Heat to reflux for 24 hours.

[0039] (3) After the reaction, centrifuge and wash with secondary water and ethanol for several times, and finally dry the centrifuged product in a vacuum oven at 20° C. for 15 hours to obtain nitrogen-doped graphene powder.

[0040] After the reaction was completed, it was centrifuged, the product was washed three times with absolute ethanol, and the product was vacuum-dried at 50°C for 12h

[0041] (4) Take by weighing 15mg of nitrogen-doped graphene powder in the mixed solution of 70mL of secondary water and ethanol (1.2:1.0), ultr...

Embodiment 3

[0043] (1) Weigh 50 mg of graphene oxide powder in 50 mL of twice distilled water, and disperse it into a uniform solution by ultrasonication for 4 hours.

[0044] (2) Adjust the graphene dispersion to a pH of about 10 with ammoniacal liquor with a mass concentration of 30%, then add 1.2mL of hydrazine hydrate with a mass concentration of 85% and stir for 10 minutes, and place the resulting mixed solution at 50°C Heat to reflux for 24 hours.

[0045] (3) After the reaction, centrifuged and washed several times with secondary water and ethanol, and finally the centrifuged product was dried in a vacuum oven at 30° C. for 12 hours to obtain nitrogen-doped graphene powder.

[0046] (4) Take by weighing 15mg of nitrogen-doped graphene powder in the mixed solution of 70mL of secondary water and ethanol (1.0:1.0), ultrasonic for 30 minutes, after making it uniformly dispersed, add 560mg of cobalt acetate tetrahydrate and 170mg of thiourea, Continue to sonicate for 15 minutes and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com