Cutting tool fully-automatic detection system

A detection system and automatic detection technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of inability to guarantee the dimensional accuracy of processed products, delays in machine adjustment and frequent tool changes, waste of raw materials for processed products, etc., to achieve measurement The effect of high speed, improving the efficiency of tool use, and saving the cost of tool use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

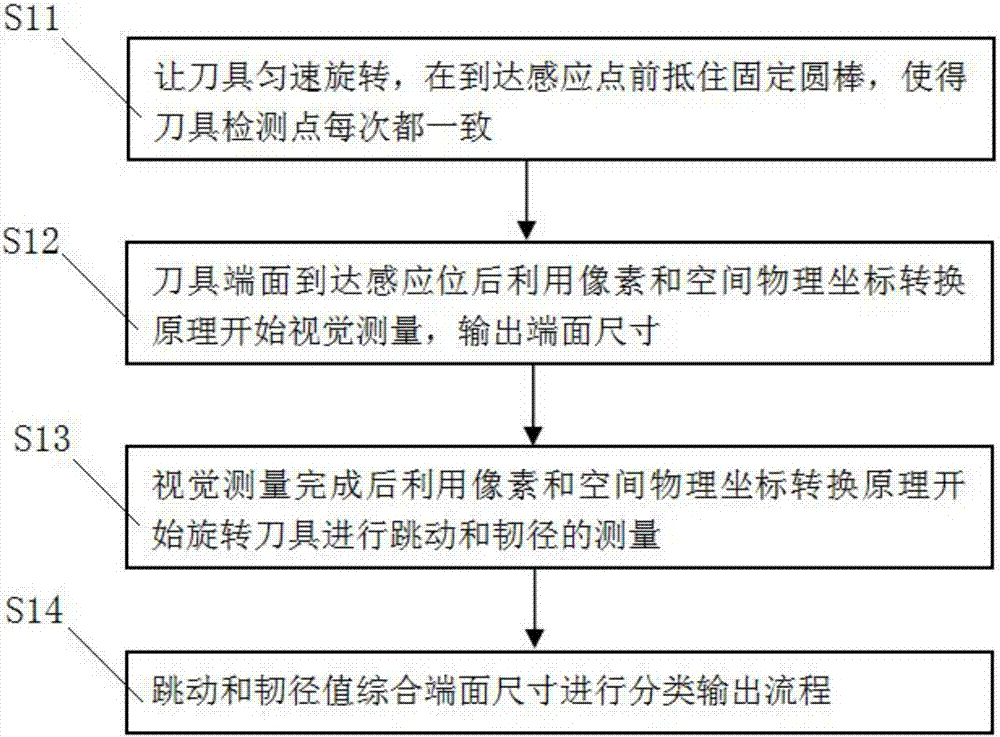

[0023] Such as figure 1 , 2 As shown, a tool automatic detection system is characterized in that it includes a tool size data entry step and an automatic detection step:

[0024] The tool size data entry steps include:

[0025] S11. Let the tool rotate at a constant speed, and press against the fixed round rod before reaching the sensing point, so that the tool detection point is consistent every time;

[0026] S12. After the end face of the tool reaches the sensing position, visual measurement is started using the pixel and space physical coordinate conversion principle, and the end face size is output;

[0027] S13. After the visual measurement is completed, use the pixel and space physical coordinate transformation principle to start rotating the tool to measure the runout and toughness diameter;

[0028] S14. Classification and output process of runout and toughness value based on end face size;

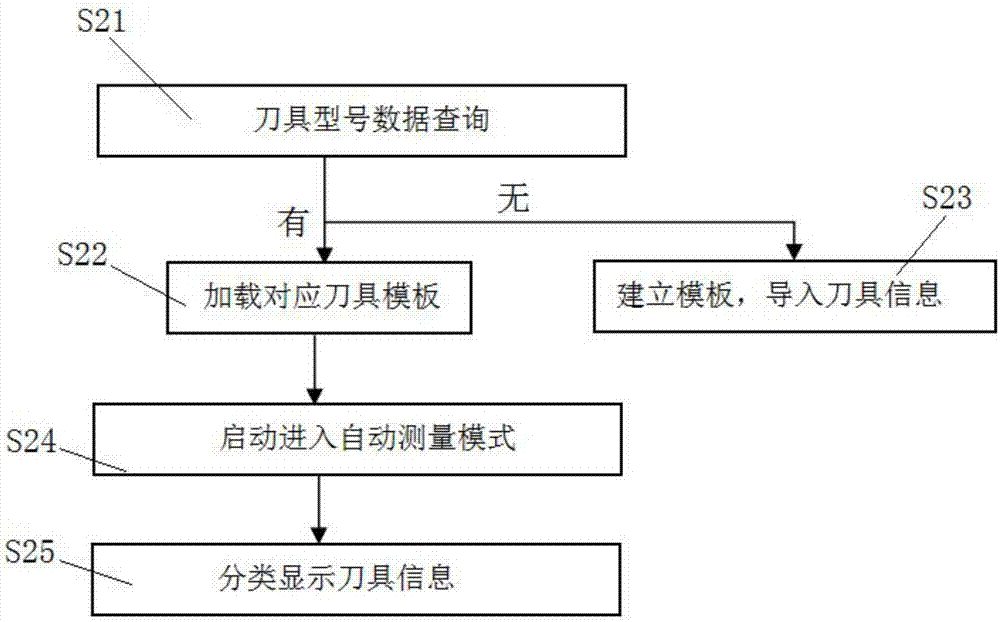

[0029] Described automatic detection step comprises:

[0030] S21, tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com