Carpet processing, pre-evaporating and flatting operation platform device

An operating table, pre-steaming technology, used in high-pressure cleaning, textile and papermaking, spray/jet textile material processing, etc., can solve problems affecting work efficiency and processing cost, uneven angle of felt, increase defect rate, etc., to achieve functional Improve, improve efficiency and effect, the effect of timely cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

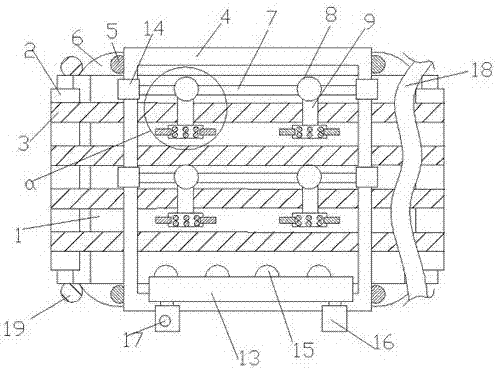

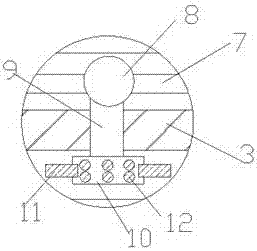

[0015] Such as figure 1 , 2 As shown: a carpet processing pre-steaming and flattening operation table device of this embodiment, including an operation table 1, a steam pre-spray pipe 18 is provided on the operation table 1, and transmission rollers 2 are provided on both sides, and two The transmission rollers 2 are connected and fixed by several conveyor belts 3; a fixed frame 4 is provided directly above the operation table 1, wherein the fixed frame 4 is connected with the adjustment disc 6 on the operation table 1 through a spring 5 Fixed; one end of the adjusting disc 6 is adapted to mesh with the adjusting gear 19 .

[0016] Several fastening rods 7 are sequentially arranged on the fixed frame 1 , and both ends of each fastening rod 7 are slidably fixed on the fixed frame 4 through a slider 14 .

[0017] Several fixing parts 8 are slidably fixed on each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com