A machining fixture for large overhang casing parts in a narrow space

A technology of parts processing and large space, applied in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, can solve the problems of unsupported, small processing space, etc., to eliminate processing vibration, improve system rigidity, and realize component processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

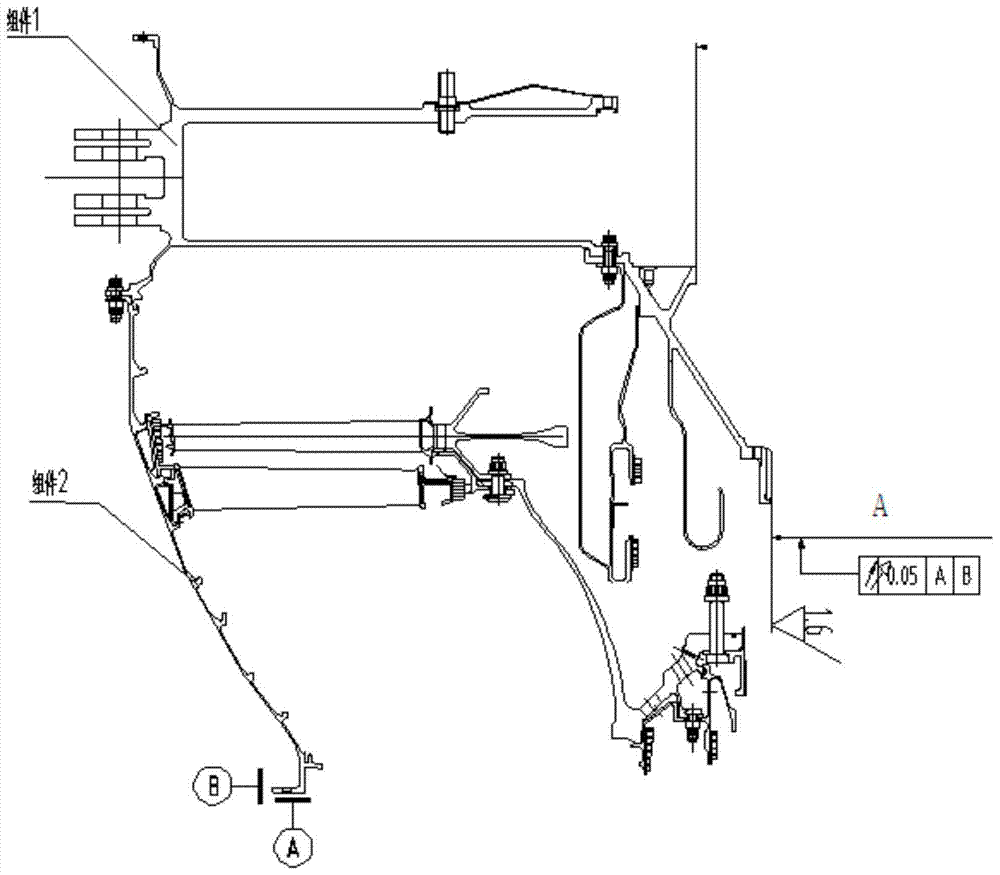

[0014] The present invention is specifically described below in conjunction with accompanying drawing, figure 1 It is a schematic diagram of the processing of a certain assembly. The assembly is composed of component 1 and component 2. After the assembly, the processing size ΦA, the technical conditions fluctuate by 0.05 relative to the benchmarks A and B, the processing part itself is a cantilever structure, and the distance between the processing part and the upper end surface is far, reaching 300mm, the space of the parts that can be supported in the radial direction is narrow, it is difficult to support, and the processing technology of the whole part is poor.

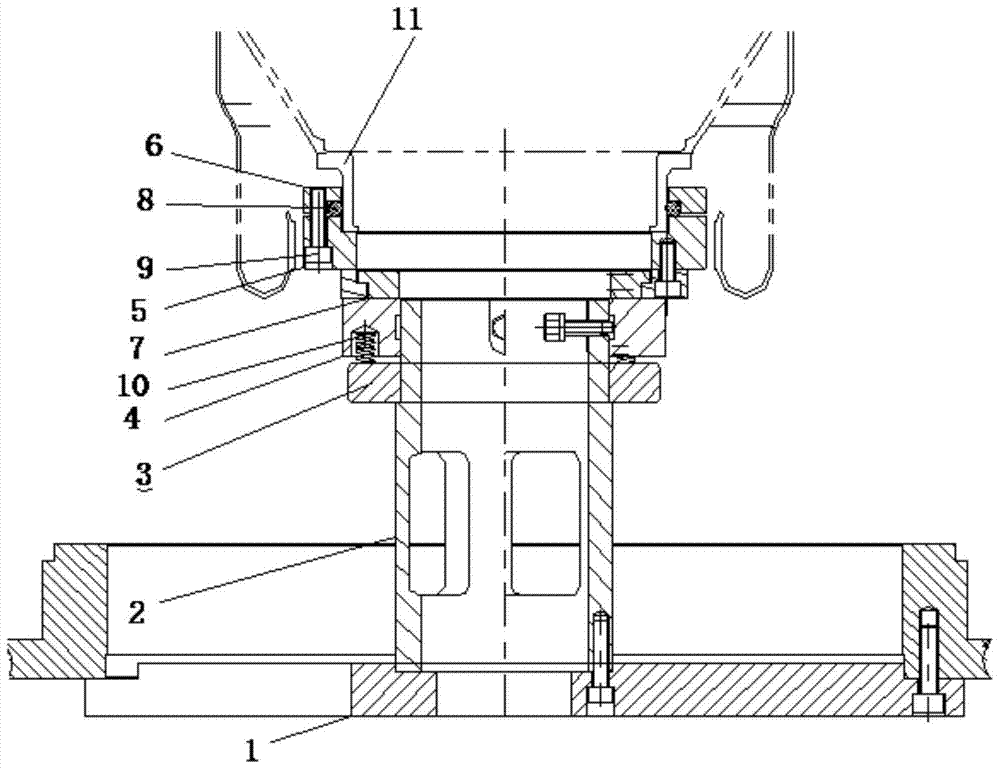

[0015] The fixture designed to solve this technical problem is as follows: figure 2 As shown, it includes a base plate 1, a support 2, a support ring 3, a guide block 4, a lower support plate 5, an upper cover plate 6, a gland 7, an O-ring 8, a screw 9, and a compression spring 10. On the base plate 1 A support 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com