Flexible vibration damping mandrel for processing thin-walled pipe parts and clamping method thereof

A technology for thin-walled tubes and parts, applied in the field of flexible vibration-absorbing mandrels and clamping, can solve problems such as cumbersome operations, polluting the environment, and large length-to-diameter ratios, and achieve increased rigidity and damping, simple and easy operation, and elimination of machining The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

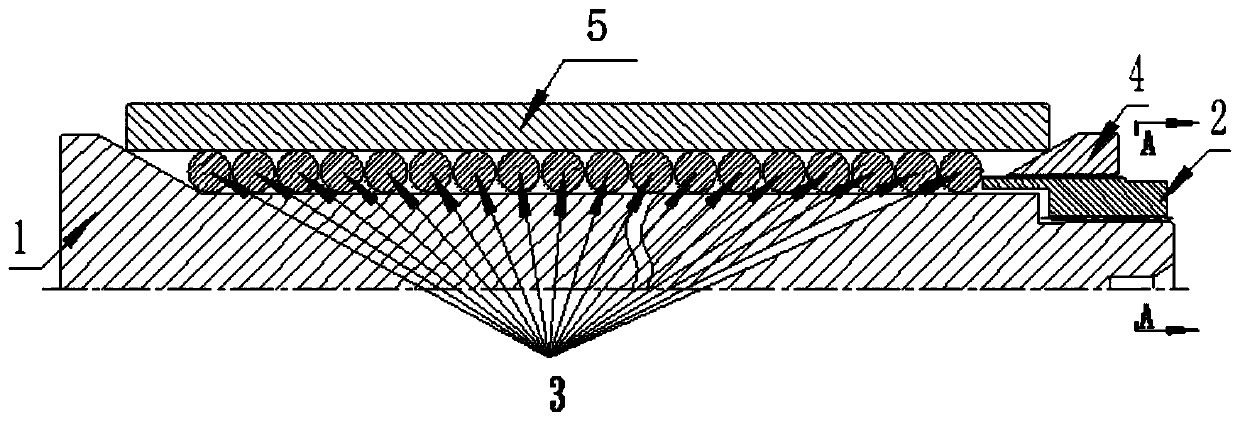

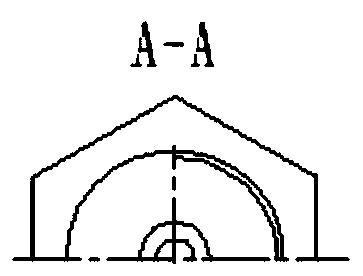

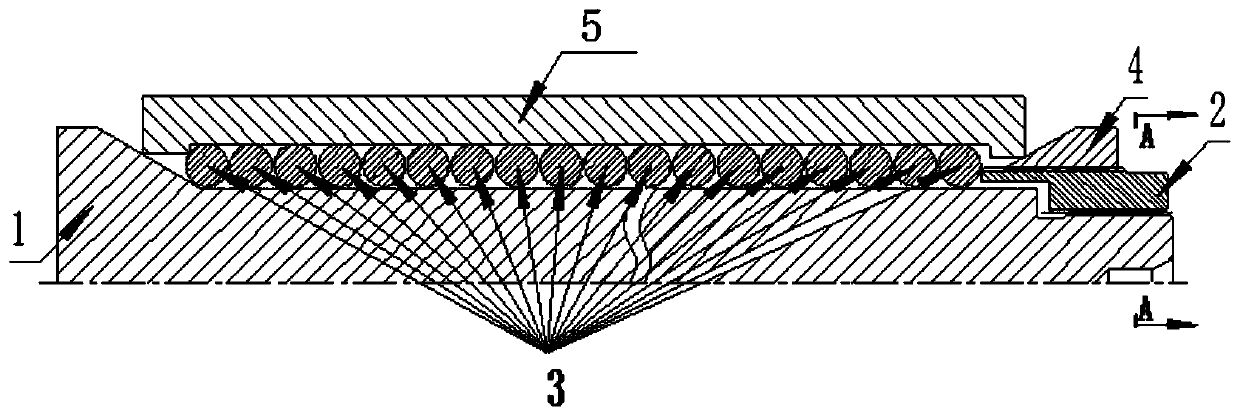

[0037] Thin-walled pipe parts have 5 small openings and large inside. The inner diameter of the "big inside" is Φ113.7mm and the length is 665mm. A group of 125 O-rings 103×5.3-G-N-GB / T 3452.1-2005 using GB / T3452 standard. The middle section of the mandrel body 1 has a straight outer circle of Φ103mm, the end surface of the second end has a GB / T4459.5-A10 / 21.2 center hole, and the outer circle of the second end has an M80 external thread. The O-ring lock nut and the mandrel body 1 are screwed together with an M80 thread and have an M105 external thread. The lock nut of the parts and the O-ring lock nut are screwed together with M105 thread. Both the outer circle of the first end of the mandrel body 1 and the two nuts adopt an outer hexagonal structure for clamping and tightening.

[0038] Put 125 O-rings into the thin-walled tubular parts 5 first, then insert the mandrel body 1 into the inner hole of the O-ring group, compress the O-ring axially with the O-ring lock nut, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com