An assembly method of an aero-engine precision fit ring assembly

An aero-engine and precision matching technology, which is applied in the field of assembly of parts, can solve the problems of micro-deformation of precision components, shape and position tolerance of precision components, and difficulty in ensuring assembly accuracy, so as to improve assembly accuracy, assembly efficiency and assembly accuracy. , the effect of reducing the number of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

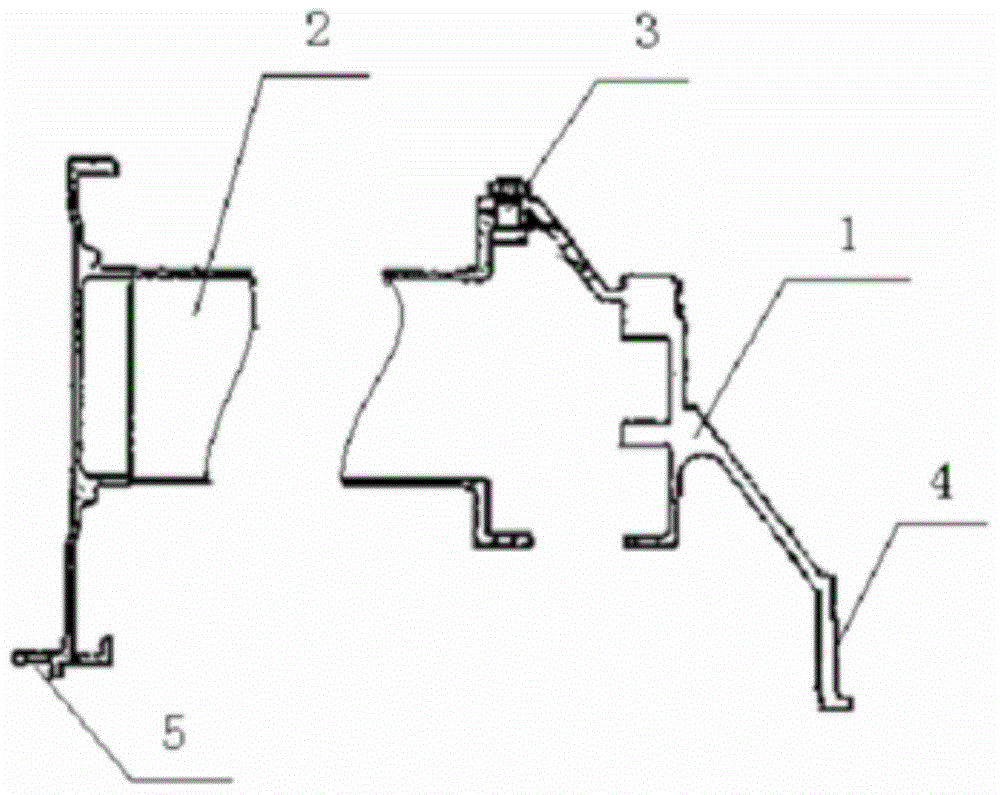

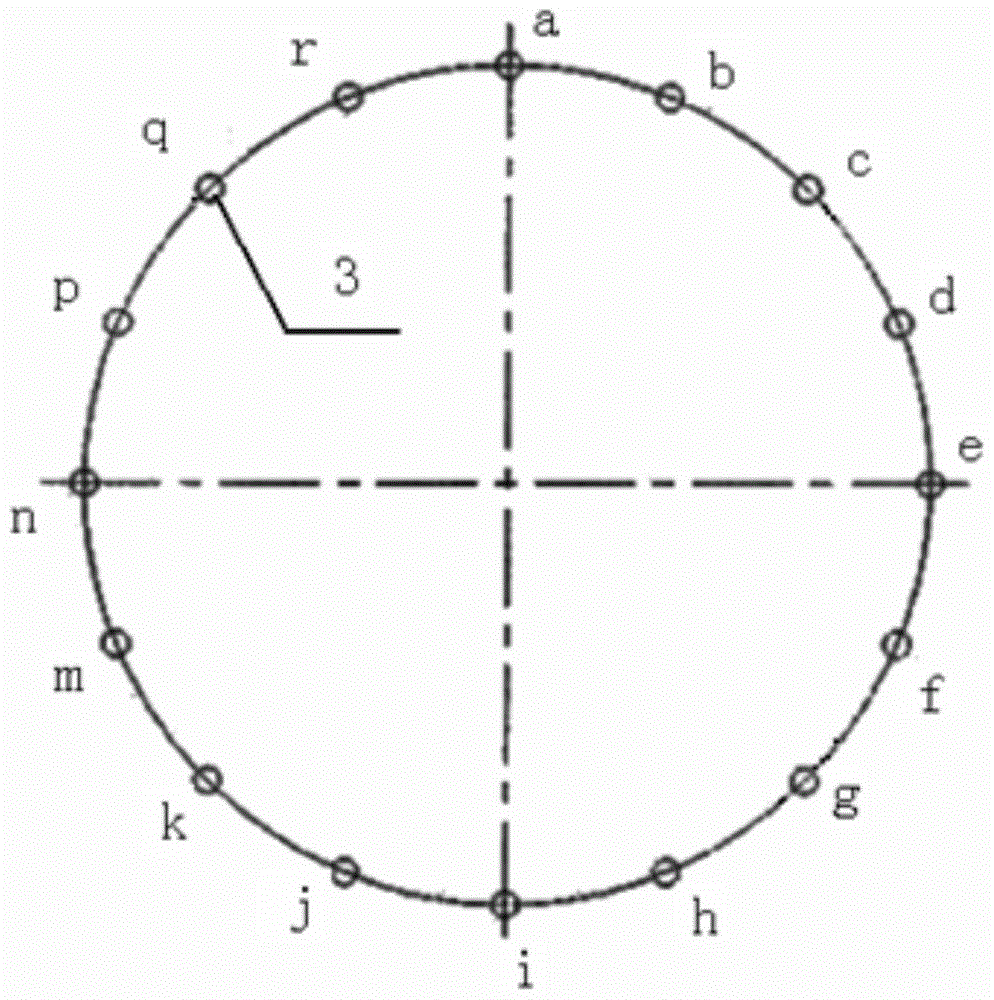

[0016] like figure 1 , 2 As shown, the aero-engine precision fit ring assembly includes an inner ring 1 and an outer ring 2. The inner ring 1 and the outer ring 2 are precisely matched and fixed with 16 precision bolts 3. The design requirements of the precision bolts 3 are to be tightened. The torque is 5KN. After the ring assembly is assembled, it is required that the runout of the inner surface 4 of the inner ring relative to the reference 5 of the outer ring is less than 0.02mm. The assembly method of the ring assembly includes the following steps:

[0017] (1) The inner ring part 1 and the outer ring part 2 are installed together, and the precision bolt 3 is placed in the initial position; select the precision bolt 3a, and the precision bolt 3i which is symmetrical with the position of the precision bolt 3a, and then select the two precision bolts 3i The bolts 3 are precision bolts 3n and precision bolts 3e in the vertical direction, and these four precision bolts 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com