Roller type breaker

A technology of roller crusher and feeding hopper, applied in grain processing and other directions, can solve the problems of blockage, large physical labor intensity, affecting raw material crushing and drying system operation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

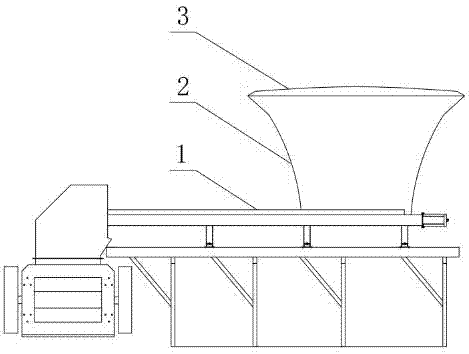

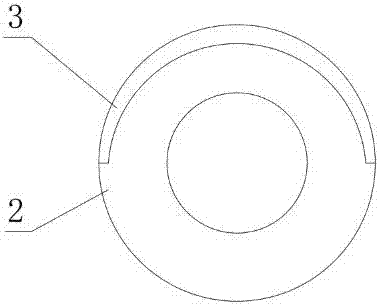

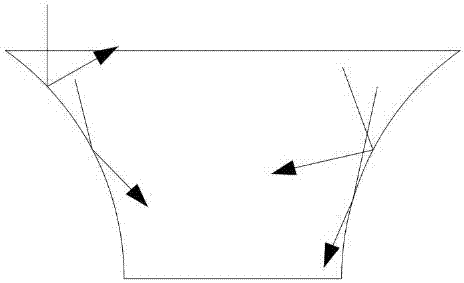

[0017] like figure 1 , figure 2 and image 3 As shown, a roll crusher 1 includes a feed hopper 2, the feed hopper 2 is an arc-shaped plate structure, and the arc-shaped plate structure is an arc that expands from bottom to top. When the wet ore falls onto the feed hopper 2, since the contact mode between the wet material and the feed hopper 2 is point contact, it is difficult to stick to the feed hopper 2. And there is no feeding dead angle in the arc-shaped structure, and the wet material will not be stuck on the feeding hopper 2, which further enhances the smoothness of feeding.

[0018] In order to further reduce the sticking of wet material on the feed hopper 2, the feed hopper 2 is configured as a circular arc plate structure. The circular arc plate structure is more rounded than the ordinary arc plate. After the material collid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com