Sealant production device and system

A production device and sealant technology, which is applied in the direction of feeding device, adhesive, transportation and packaging, etc., can solve the problems of short storage period and poor quality of finished products, and achieve the effect of improving the quality of finished products, avoiding quality problems and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

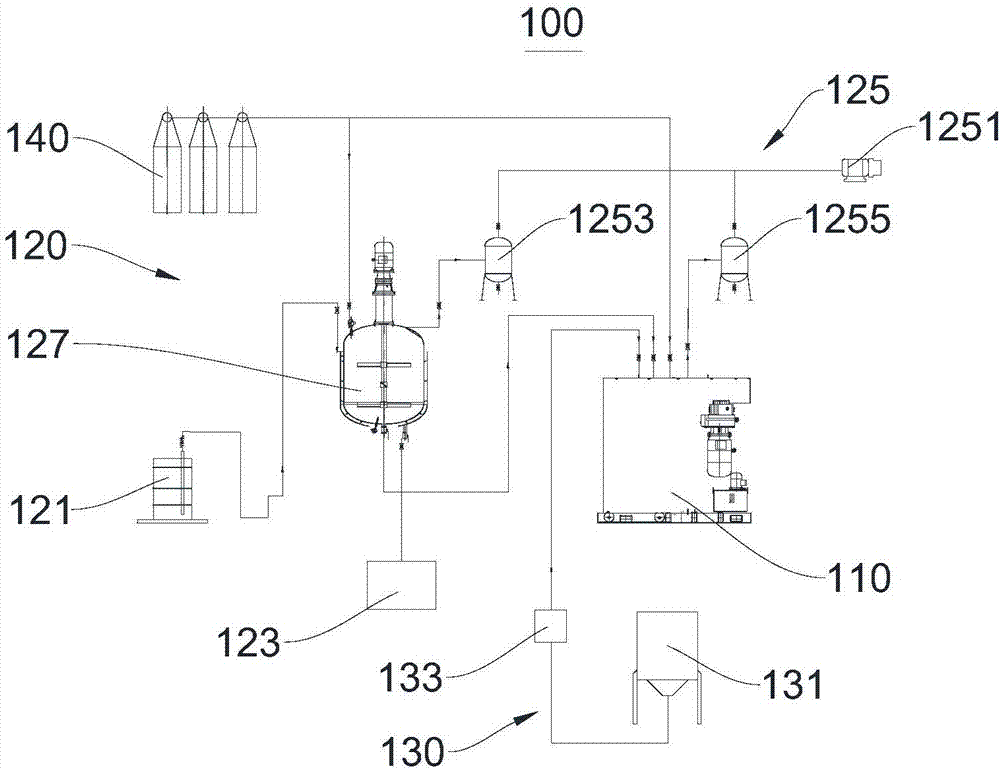

[0031] Please refer to figure 1 , this embodiment provides a sealant production device 100, including a mixing device 110, a first processing device 120 that supplies the first raw material to the mixing device 110, and a second processing device 130 that provides the second raw material to the mixing device 110 .

[0032] In the mixing device 110, the first raw material is a prepolymer obtained through polymerization. The first processing device 120 includes a raw material barrel 121 , a reaction kettle 127 matched with a temperature control device 123 and a vacuum generator 125 . The raw material barrel 121 , the reaction kettle 127 and the mixing device 110 are sequentially connected through pipelines to form a closed first conveying channel.

[0033] In the production process of the sealant, the raw materials need to be vacuum dehydrated under a certain vacuum degree, so the vacuum generator 125 is used to adjust the vacuum degree in the reaction kettle 127 . Specifical...

Embodiment 2

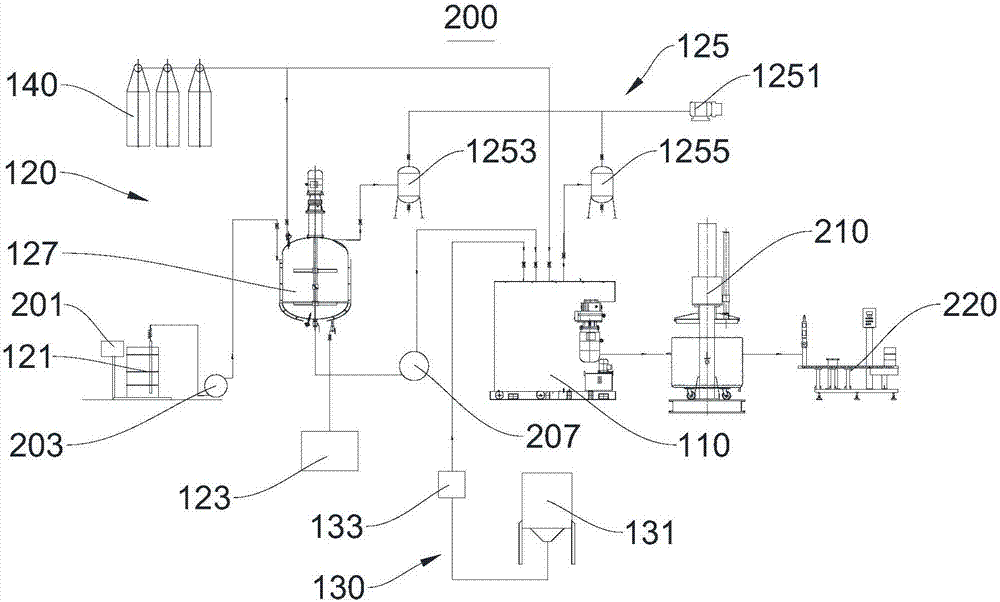

[0043] Please refer to figure 2 , this embodiment provides a sealant production device 200 .

[0044] The difference between the sealant production device 200 and the sealant production device 100 mainly lies in:

[0045] In order to add the first raw material into the reactor 127 more accurately, the first delivery channel is provided with a first weighing device 201 . The first weighing device 201 is connected with the raw material barrel 121, and is used for weighing the mass of the first raw material to be reacted, and reacting it in an optimal amount. On the one hand, the addition amount of the first raw material is more accurate, avoiding waste caused by incomplete reaction due to inaccurate addition; on the other hand, it replaces manual addition, reduces manual measurement errors, improves work efficiency, and prevents sealant production Air enters into the device 200, causing the raw materials to absorb moisture and affecting the performance of the product.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com