Basin excavation short support supporting system and construction technology thereof

A technology of basin-type excavation and construction technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of large construction period impact, long construction period, waste and other problems, and achieve the effect of saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

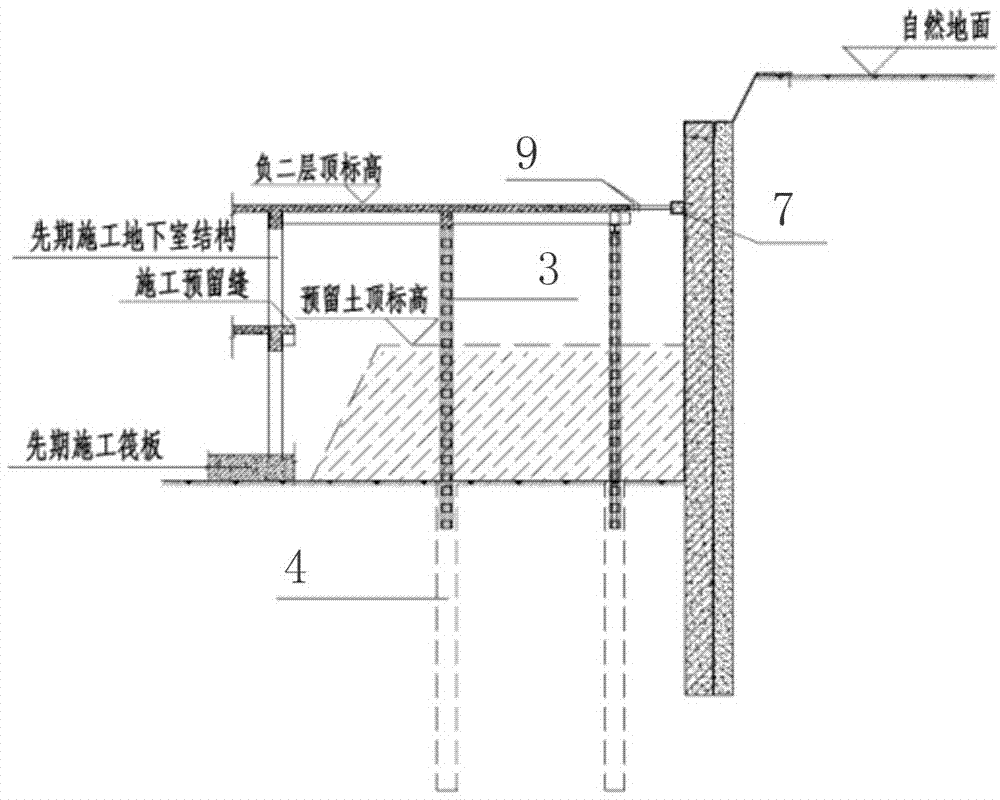

[0048] The depth of the foundation pit is 17.0m, and the surrounding environmental conditions of the foundation pit are complex, and there is no external anchor condition. The design intends to adopt the short support system of basin excavation. A basin-type excavation short support support system, including a beam-slab structure 6 located in the middle of the foundation pit and a soil retaining structure 1 located at the side wall of the foundation pit, the bottom of the beam-slab structure 6 is provided with a vertical support system; the beam A steel support 10 is arranged horizontally between the plate structure 6 and the retaining structure 1 , and the steel support 10 is connected to the retaining structure 1 through purlins 7 .

[0049] Its construction techniques, such as Figure 1-6 shown, including the following steps:

[0050] 1) Construction of the soil retaining structure 1, the soil retaining structure 1 is a row of piles, and the row of piles is a concrete pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com