Preparation method of fine dry silk product

A technology of refined and dried silk, which is applied in the field of silk processing, can solve the problems of poor quality, easy cake knots in silk tires, easy hardening of silk quilts, etc., and achieves the effects of eliminating static electricity, good bulkiness, and eliminating chemical residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

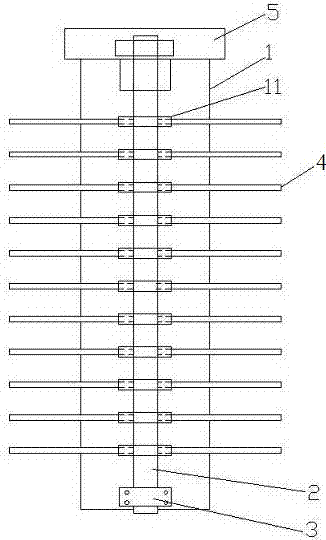

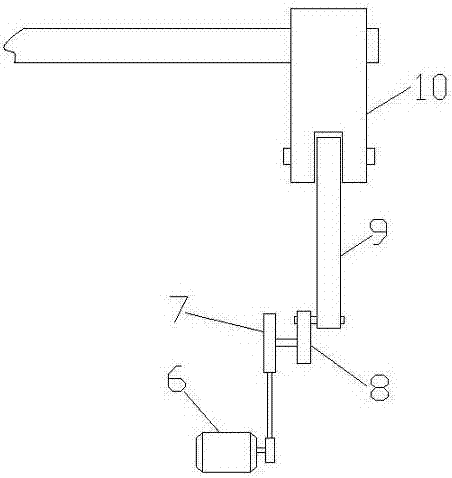

Image

Examples

Embodiment 1

[0030] The method for preparing dried silk product comprises the following steps in turn: putting silk cocoons into a scourer for soaking, adding 5% of the cocoon weight of soda ash and 1% of the silk cocoon weight of detergent and keeping the pH of the soaking solution at 8.5-10.5, controlling The water temperature is 80°C, and the soaking time is 12 hours; the soaked silkworm cocoons are taken out of the washing machine and put into the dehydrator for the first dehydration; the silkworm cocoons after the first dehydration are opened by the cotton opener to form cotton sheets; the cotton sheets are put into the water tank For the second soaking, add 3% soda ash based on the weight of the sheet, control the water temperature at 80°C, and soak for 60 hours; after the second soaking, the sheet is dehydrated twice, then rinsed, and then dehydrated three times; the sheet after the third dehydration Put it in the water tank for bleaching, add 20% hydrogen peroxide of the weight of t...

Embodiment 2

[0034] In Example 2: add 9% soda ash and 1.3% detergent based on silkworm cocoon weight for the initial soaking, control the water temperature at 100°C, and soak for 18 hours; control the water temperature for the second soaking at 100°C, and soak for 72 hours; 40% of the sheet weight hydrogen peroxide, bleaching time 16h; wet the sheet into 32 ° C water; other steps and parameters are the same as in Example 1.

Embodiment 3

[0036] In Example 3: add 7% soda ash and 1.1% detergent based on silkworm cocoon weight for the initial soaking, control the water temperature at 90°C, and soak for 15 hours; control the water temperature for the second soaking at 90°C, and soak for 70 hours; 40% of the weight of the sheet with hydrogen peroxide, bleaching time 15h; when wet, put the sheet into water at 30°C to wet; other steps and parameters are the same as in Example 1.

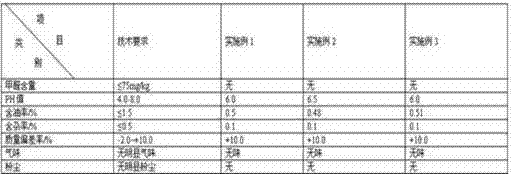

[0037] With embodiment 1, 2, 3 the fine dried product of silk made, the data detected by National Textile Products Quality Inspection and Inspection Center (Jiangyin) are as follows:

[0038]

[0039] From Examples 1, 2, and 3, it can be seen that the oil content of the dry product made by the method of the present invention is far lower than the industry standard, and the finished product made from the dry product with a low oil content is not easy to harden after washing, and the dry product after repeated rinsing The impurity rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com