Sorting method for carbel loop line sorting system and package discharging control system

A sorting system and control system technology, applied in conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of acceleration segment error, complex algorithm, low efficiency, etc., to improve sorting speed and efficiency, computing The process is simple and efficient, and the effect of simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

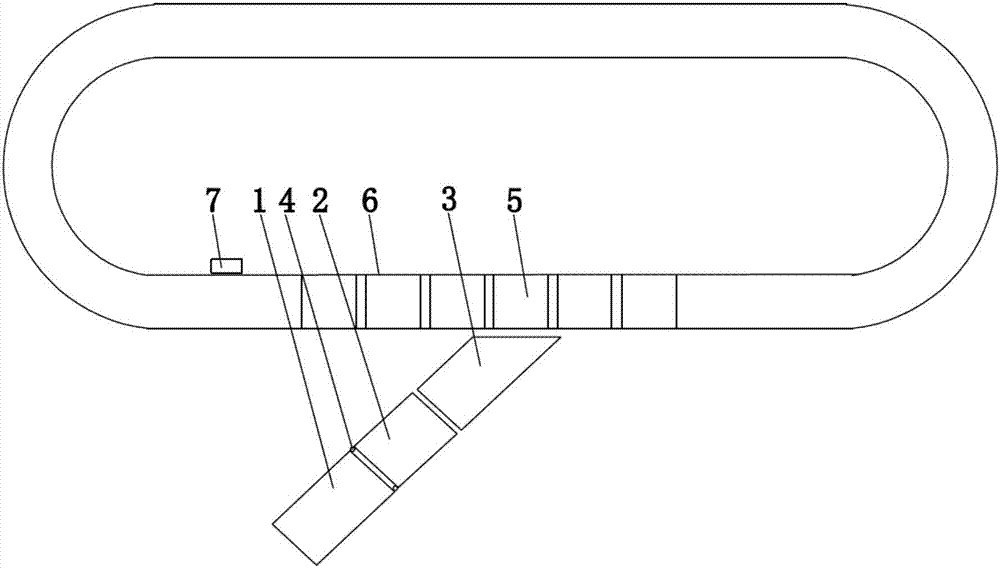

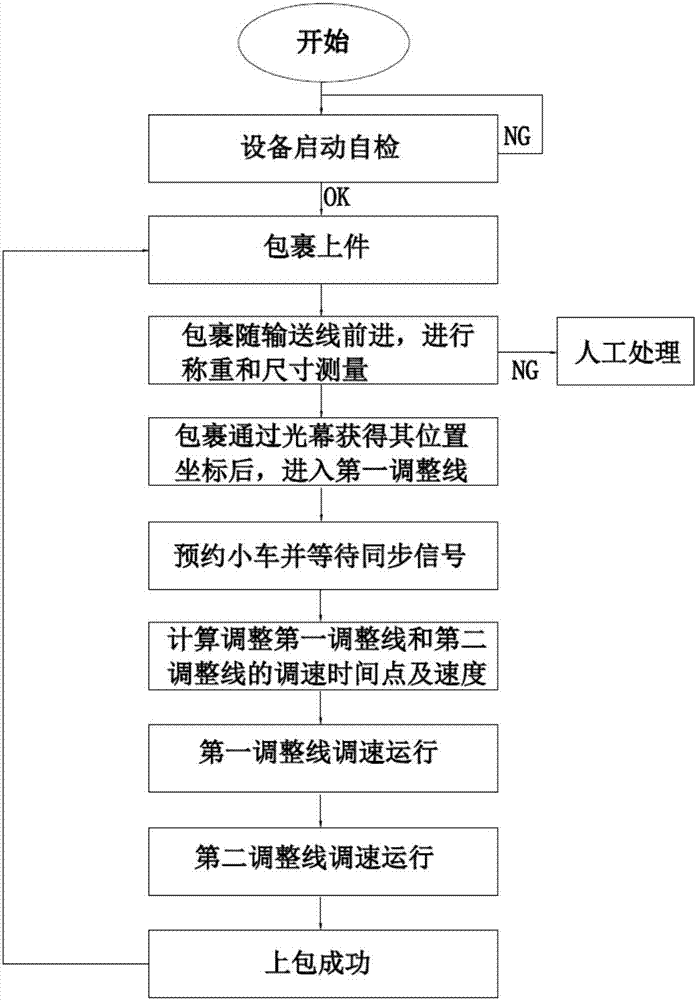

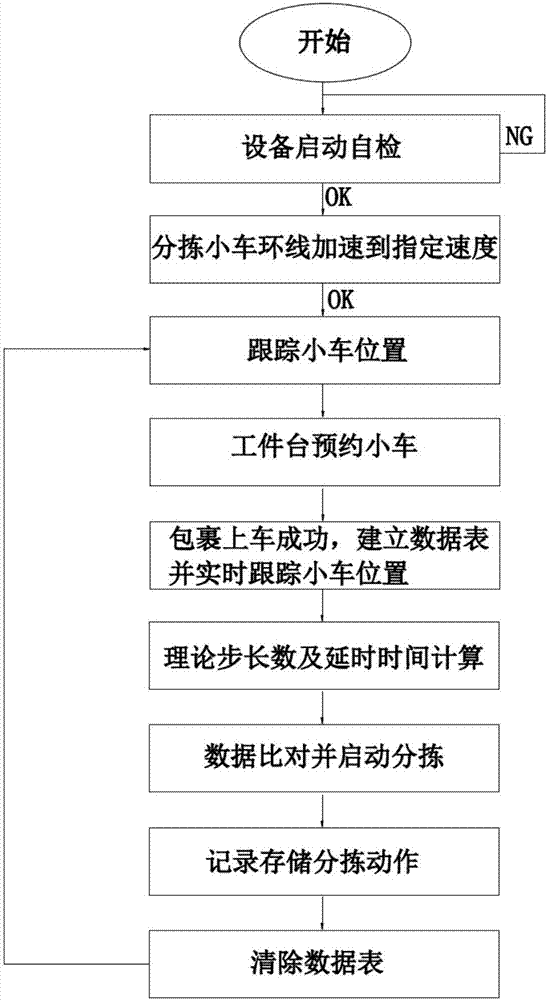

[0066] The invention discloses a sorting system for a cross belt and loop line. The cross belt loop line sorting system includes a sorting trolley loop and a package supply line for the sorting trolley loop, which are all connected to a control system.

[0067] as attached figure 1 As shown, the running speed V of the loop line 6 of the sorting trolley 环 Between 1.5m / s-2.2m / s, it includes a group of sorting carts 5 arranged at equal intervals and surrounded by a ring, each sorting cart 5 corresponds to a cart number, and a photoelectric trigger point is set on it A photoelectric sensor 7 for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com