A device and method for locally strengthening the elastic mold of a microfluidic chip

一种微流控芯片、弹性模具的技术,应用在家里用具、其他家里用具、纳米技术等方向,能够解决提高的幅度有限等问题,达到增强机械强度、机械强度加强的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

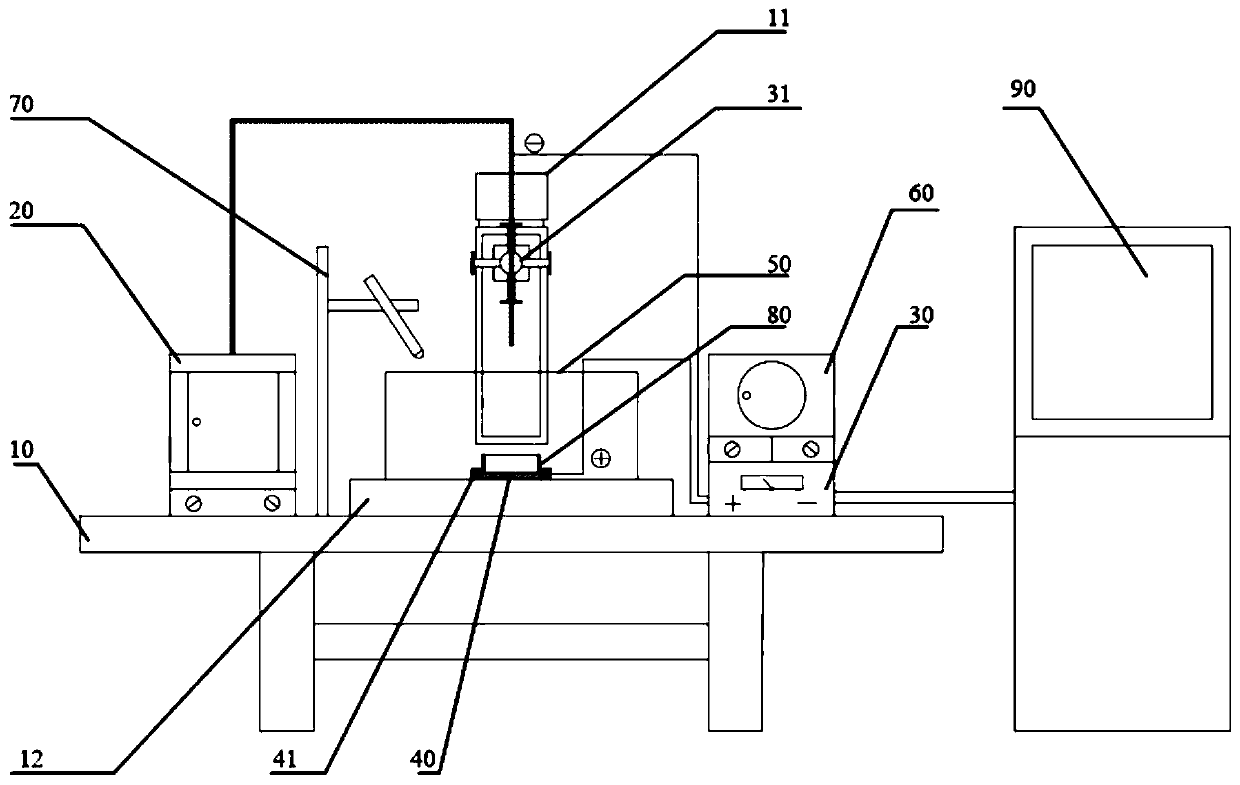

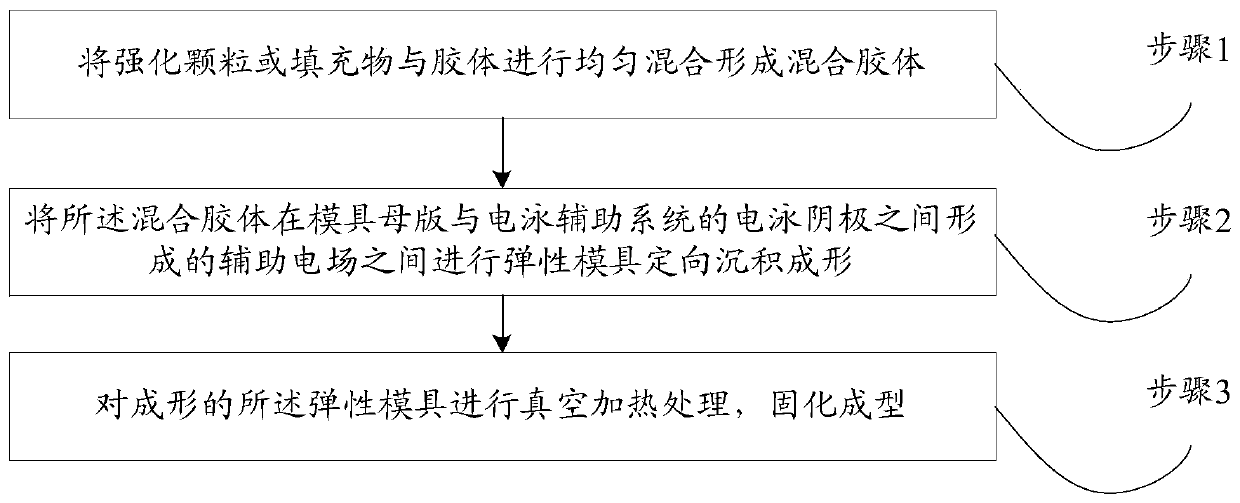

[0034] Please refer to Figure 1 ~ Figure 2 , figure 1 A structural schematic diagram of a specific embodiment of a microfluidic chip elastic mold local reinforcement molding device provided by the embodiment of the present invention; figure 2 It is a schematic flow chart of the steps of a specific implementation of the local reinforcement molding method for the elastic mold of the microfluidic chip provided by the embodiment of the present invention.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com