Dead head grinding and labeling device

A labeling and equipment technology, applied in labeling machines, casting molding equipment, metal processing equipment, etc., can solve the problems of grinding the inner wall of the riser and slow efficiency, so as to speed up the labeling speed, improve the accuracy and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

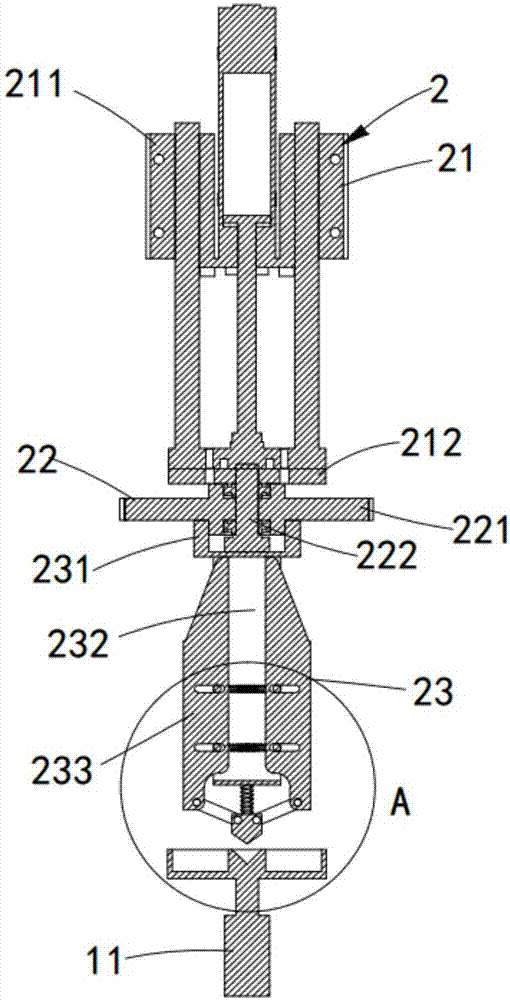

[0080] Such as figure 1 As shown, a riser grinding and labeling equipment includes a frame 1, the lower part of the frame 1 is provided with a workbench 11, and the workbench 11 is provided with a riser positioning seat 12, and also includes:

[0081] Grinding mechanism 2, said grinding mechanism 2 is arranged on the top of frame 1, which is located directly above workbench 11, and it is used for grinding the inner arm of riser, and this grinding mechanism 2 includes lifting assembly 21 from top to bottom , the first rotating assembly 22 and the grinding assembly 23;

[0082] Labeling mechanism 3, described labeling mechanism 3 is arranged on the workbench 11, and it is used for carrying out the labeling work to riser side wall, and this labeling mechanism 3 comprises paper feeding assembly 31, clamping assembly 32, and labeling Component 33;

[0083] The driving mechanism 4 is rotatably arranged on the workbench 11 and is used to drive the grinding mechanism 2 and the label...

Embodiment approach

[0129] Such as Figure 13 As shown, as a preferred embodiment, the drive mechanism 4 includes:

[0130] A driving motor 41, the driving motor 41 is fixedly arranged under the workbench 11;

[0131] Rotating shaft 42, said rotating shaft 42 is concentrically connected with the motor shaft of said drive motor 41, and it is driven to rotate by this drive motor 41;

[0132] V-shaped bracket 43, the V-shaped bracket 43 is sleeved on the rotating shaft 42, and its lower end is fixedly connected with the workbench 11;

[0133] The driving gear 44, the driving gear 44 is located at the lower part of the V-shaped bracket 43, it is sleeved on the rotating shaft 42, and it is used to drive the clamping assembly 32 to rotate;

[0134] The toothed roller 45 is located on the upper part of the V-shaped bracket 43 and sleeved on the top of the rotating shaft 42 to drive the first rotating assembly 22 to rotate.

[0135] It should be specified that the drive motor 41 drives the driving gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com