A planar trigger type low jitter long life gas spark gap switch

A gas spark gap and low jitter technology, which is applied to spark gaps with auxiliary trigger devices, spark gaps, spark gap components, etc., can solve the problems of switch performance changes, poor switch consistency, and short life, and reduce output jitter , The switch performance is consistent, and the effect of improving the stability of the switch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

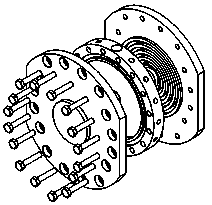

[0027] Attached below Figure 1-4 The present invention is further described.

[0028] The structure of the present invention is as figure 1 As shown, it includes a trigger plate and two plexiglass insulating covers on both sides of the trigger plate. Use nylon screws to tighten the two plexiglass insulating covers and fix the trigger plate in the middle.

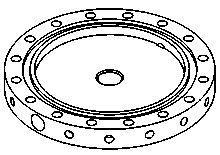

[0029] like figure 2 As shown, the two bottom surfaces of the trigger plate are provided with concave table tops, the edges of the two bottom surfaces are provided with sealing grooves, and a pair of through holes and several threaded holes are symmetrically distributed on the circumferential surface.

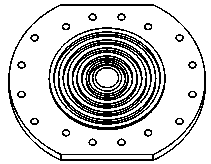

[0030] like image 3 As shown, several concentric rings are provided on the inner side of the insulating cover, and each concentric ring protrudes to the same height along the axis of the insulating cover.

[0031] like Figure 4 As shown, the outer surface of the insulating cover is provided with a concave table, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com